EDIT 24 Oct 2018 The schematic in this post contains an error. It will be reposted after receipt of the PCB and testing.

I am developing an inexpensive but reasonably accurate meter for measuring resistance in the milliohm range. The previous posts are listed in the related links at the bottom. In this post the design for the working prototype is expanded to include a second current source for measuring resistance up to 400 ohm and provision made for future auto-ranging. A new schematic and a PCB design are presented along with an update on meter options.

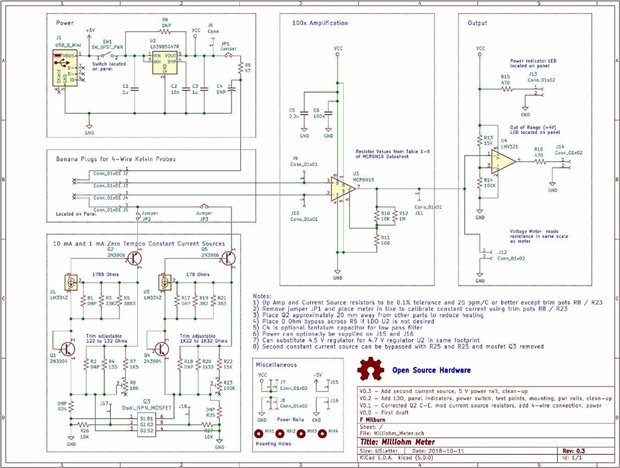

Revised Schematic

The revised schematic is shown below:

The added current source is identical to the first but designed for 1 mA current. A dual N-Channel MOSFET with pull-down resistors is connected just above ground to allow selection of a source. It will add maybe an ohm to ground. There are jumpers and bypass resistors so that the second current source and MOSFETs can be omitted if desired. This has not been incorporated into the working prototype so a second eye and comments on the design are welcome. An additional 5V set of pins was added so a source other than the USB connection could be used as well. Thanks for ideas and suggestions shabaz  .

.

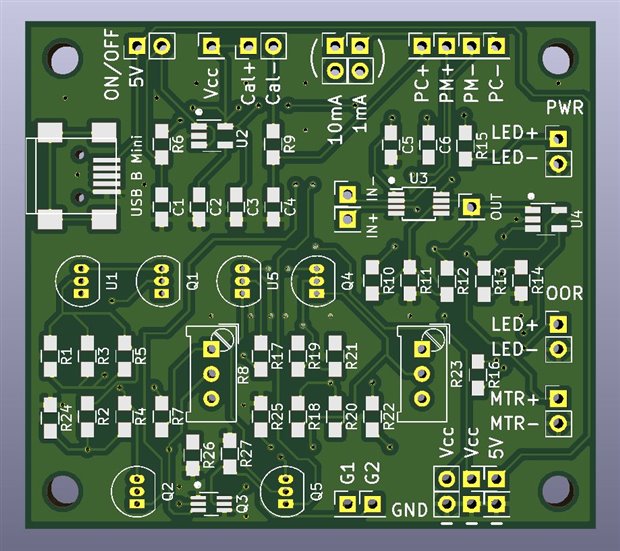

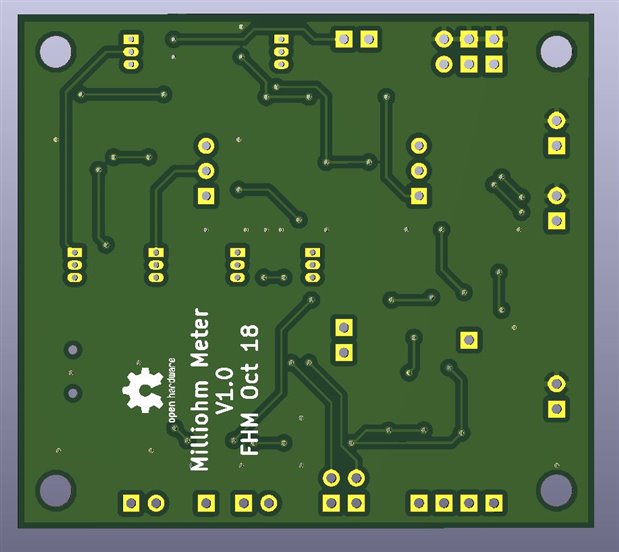

PCB Design

The PCB was done in KiCad (5.0.0) which is a new version for me and I am still finding my way around the changes. The layout was done with ease of hand soldering in mind which led to what I consider poor routing so I may redo it and hope send it to the board house tomorrow. There were a couple of unfinished wires when the renders below were made but those are finished now and it passes electrical check.

Panel Meters and Alternate Current Sources

The panel meter I ordered from China came in earlier in the week but they were a disappointment. Although they advertised 5 digit resolution they are not much better than 3 and show zero when down in the low millivolt range so they aren't much use for this project. There is a zeroing procedure which I tried without much luck and a small pot which doesn't seem to do much. I also ordered a ammeter but haven't had a chance to really test it. It looks like I will be using patch cables and a multimeter for the display.

I also finally got the other current sources I was going to test for the project but time is running out and the LM334 really works good so I will put those aside for a later time.

Next Steps

This week I also plan to finish preparation of the BOM and order the parts that aren't in hand but there probably won't be any more posts until after the PCBs are back in about 2 weeks time. As always, comments and corrections are appreciated.

Related Links

Testing Current Sources for a Kelvin (4-Wire) Milliohm Meter

More on Current Sources and a Kelvin (4-Wire) Milliohm Meter

Even More on Current Sources and a Kelvin (4-Wire) Milliohm Meter

Top Comments

-

shabaz

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

fmilburn

in reply to shabaz

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

fmilburn

in reply to shabaz

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

fmilburn

in reply to shabaz

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to fmilburn

-

Cancel

-

Vote Up

+6

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

fmilburn

in reply to shabaz

-

Cancel

-

Vote Up

+4

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to fmilburn

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

shabaz

in reply to fmilburn

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children