How Coffee Machines, Ovens, and HVAC Systems Benefit from EVE’s Graphics & Touch Features

Introduction

Smart appliances are no longer just about functionality — they’re about experience. From brewing the perfect cup of coffee to managing the home climate, consumers expect intuitive controls, sleek interfaces, and responsive feedback. Bridgetek’s Embedded Video Engine (EVE) technology makes this possible by combining graphics, touch, and audio in a single chip solution.

Coffee Machines: Brewing Made Simple

Ovens: Precision Cooking with Ease

️ HVAC Systems: Comfort at Your Fingertips

Why EVE Technology Stands Out

Conclusion

Bridgetek’s EVE technology allows designers to transform everyday appliances into smart, user‑friendly systems. Whether it’s brewing coffee, baking dinner, or managing home comfort, EVE delivers the intuitive interfaces consumers expect — helping manufacturers stay ahead in the connected appliance market.

Check out :

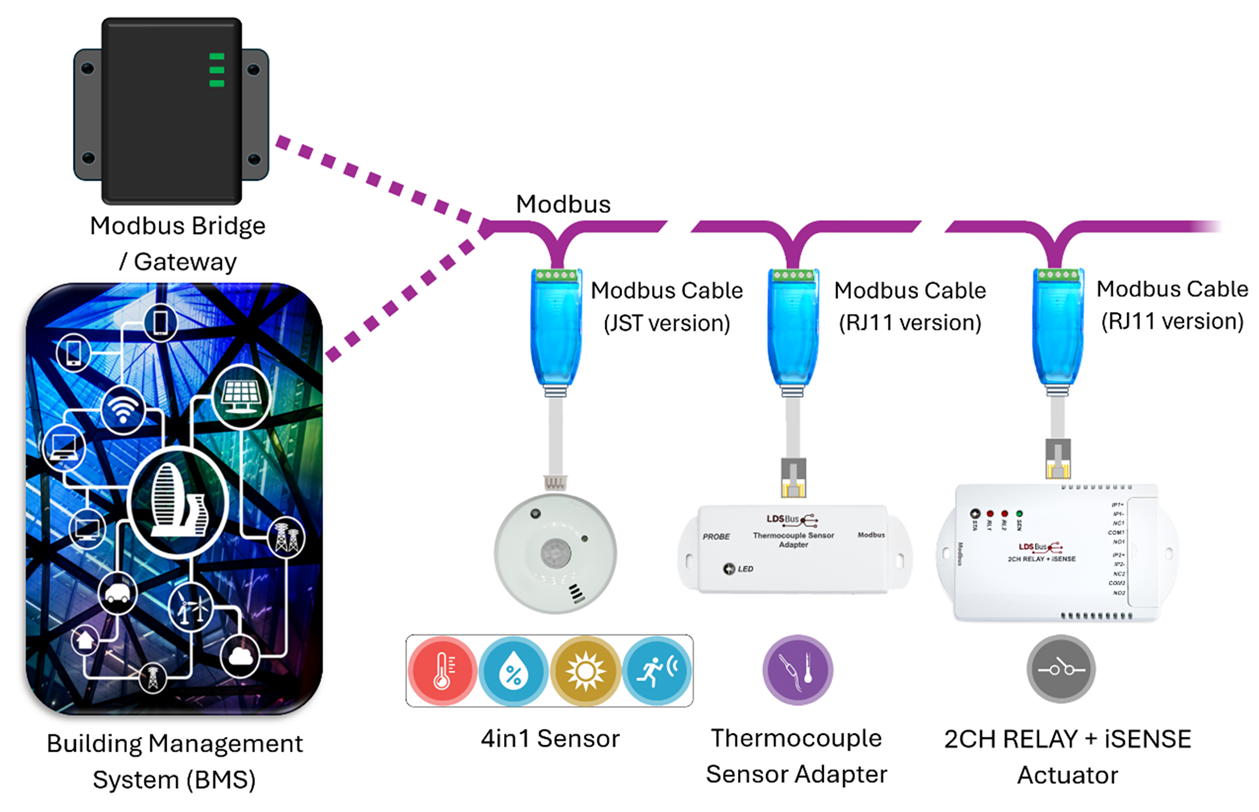

Overview

Introducing our range of sensors and actuator devices supporting the popular Modbus protocol. With robust yet aesthetically pleasing enclosures and a range of mounting options, they are ideal for connecting to new and existing Modbus systems, such as Building management controllers, smart home controls, Industrial controllers, computers, and via wireless bridges (for example Modbus to LoRaWAN bridges).

With Modbus RTU, you can daisy-chain large numbers of devices over long distances using cost-effective cabling, providing both power and data. Mix and match the sensors, sensor adapters and actuators from our range on the same network, and on existing buses with other Modbus RTU devices.

With Modbus connectivity, our sensors and actuators offer:

Modbus Products

Our range includes Sensors, Sensor Adapters, and Actuators.

Key Features

Modbus Hosts

Use our Modbus sensors and actuators with any Modbus host. Ideal for new and existing installations, connected to Building Management System controllers, smart home controls, Industrial controllers, computers, embedded systems and via wireless bridges (for example Modbus to LoRaWAN bridges) to name a few.

Use our Modbus sensors and actuators with a wide range of Modbus hosts in different applications

Get Connected!

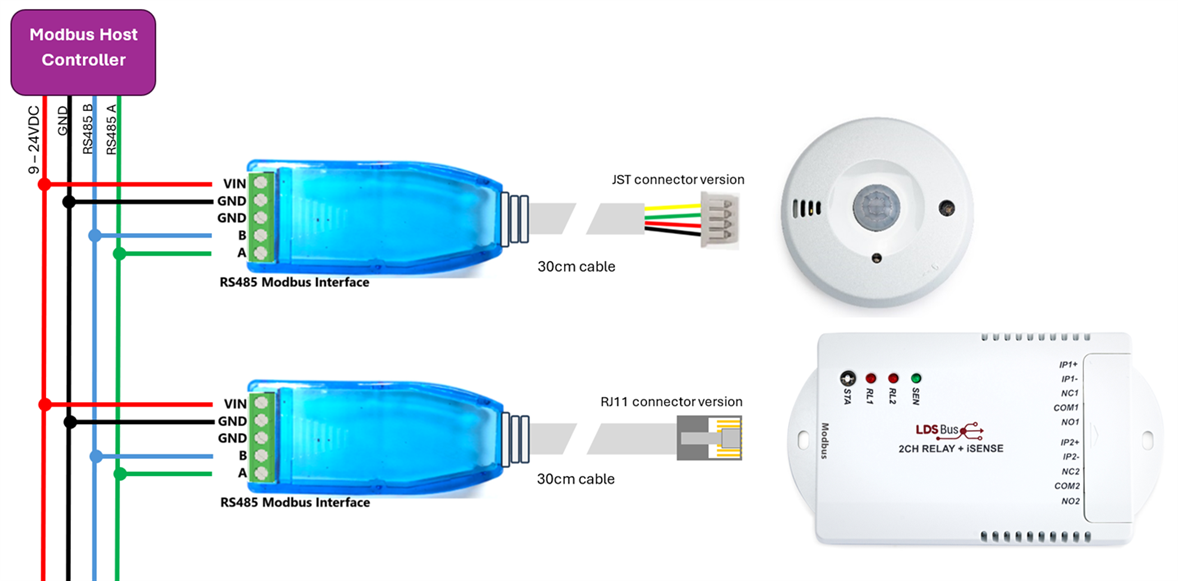

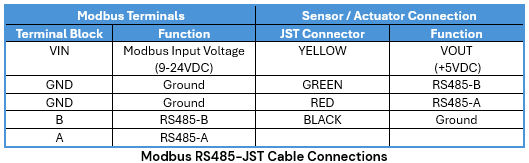

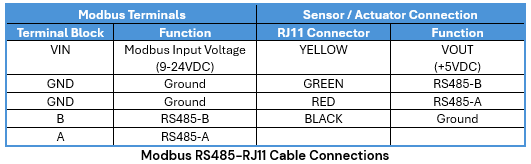

Our Modbus devices connect via convenient terminal blocks providing Modbus RTU power and data connectivity. Each device is shipped with a corresponding 30cm RS485 Modbus adapter cable to convert the on-board JST or RJ11/12 connector to a 5-way terminal block. Simply connect the RS485 A, RS485B, GND and Power (9-24V DC) to the terminals and connect the JST or RJ11/12 end to the sensor, actuator or sensor adapter.

Connecting to Modbus is easy with the RS485 Modbus cable supplied with each product

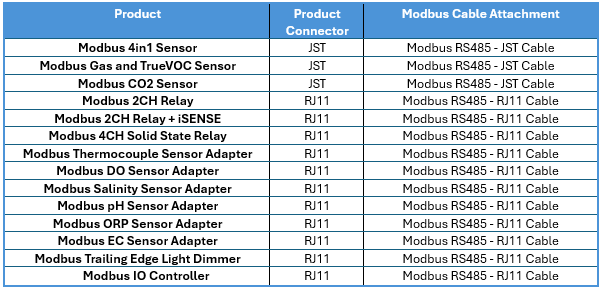

The adapter included with each product is shown below:

Modbus Devices and Cable Attachments

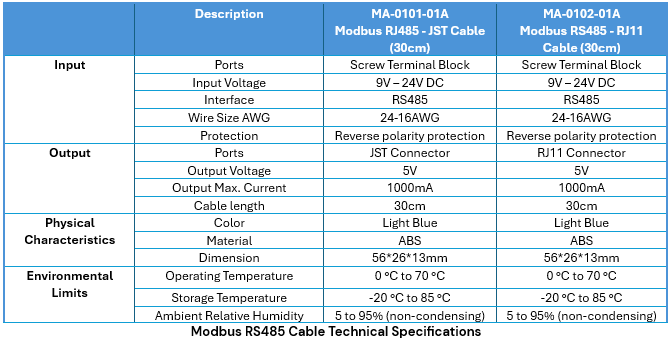

MA-0101-01A: Modbus RS485 – JST Cable (30cm)

MA-0102-01A: Modbus RS485 – RJ11 Cable (30cm)

Simple Configuration

Our Modbus Configuration Utility provides fast and easy configuration of your Modbus devices. Simply connect your sensor or actuator using a USB-RS485 adapter for initial set-up and additional configuration.

Refer to our Modbus Configuration Utility and User guide for details.

Note that address, baud rate, parity and termination can also be set using some 3rd party Modbus configuration tools

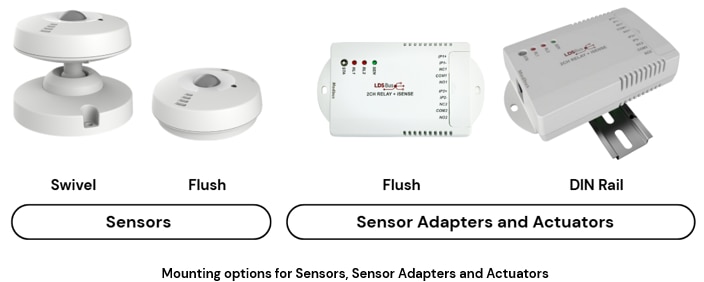

Flexible Mounting Options

Our sensors can be flush mounted on a flat surface or can be swivel-mounted using the optional swivel-mount bracket. Our Sensor Adapters and Actuators can be flush mounted using the integrated mounting ears, and can also be DIN rail mounted via the DIN Rail mounting kit (available separately).

The attractive yet discrete enclosures make the sensors ideal for use in offices, commercial/retail areas and residential applications where the sensors will be visible.

Applications

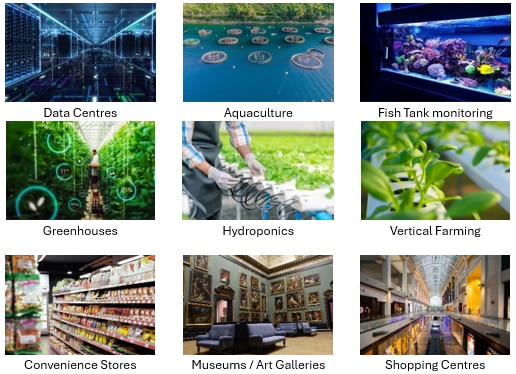

Our Modbus sensors, sensor adapters, and actuators are ideal for a wide range of applications including those shown below plus many more.

With a diverse range of sensors, you can monitor air quality and fluid properties via the same Modbus network using our sensors. You can also control a wide range of devices, including motors, pumps, fans, lighting or other devices which require a switching control via relays or even control via digital or analog signals from the Isolated IO controller (such as 0-10V dimmers).

Introduction

Adding a graphical touch HMI (Human Machine Interface) to a product is a great way to enhance the user experience. But the benefits go way beyond this: It adds flexibility to accommodate new features (both now and in future), helps overcome obsolescence of traditional controls, and enables a family of products to share a common HMI platform with strong brand visibility, while remaining easily customizable and supporting multiple languages.

Thanks to the innovative Embedded Video Engine (EVE) from Bridgetek, designing or updating products with a graphical touch display interface is fast and easy to do, even when the engineers have no prior experience with touch screen graphical HMIs. The graphical display, touch and even audio can be added to the existing MCU over SPI or Quad-SPI (QSPI). Along with extensive design software tools and examples, this solution ensures the product can benefit from the advantages in a short timescale.

Challenges

There are some cases, however, where directly connecting the EVE device to the existing system MCU or controller is not the most feasible option, requiring a slightly different approach. These include:

In the following sections, we’ll explain how the new Intelligent Display Panels (IDP) from Bridgetek help address these challenges.

Longer Distances

When designing a product with the EVE IC or modules from Bridgetek, the system MCU or controller connects to EVE over SPI or QSPI. EVE then connects to the display via RGB or LVDS, and to the touch panel via I2C (capacitive touch) or analogue signals (resistive touch).

Where the display must be located further from the MCU (for example 2m, 10m or even more than 100m), the distance limitations of the SPI/QSPI communication as well as the RGB/LVDS, analogue and I2C signals can become a challenge. Voltage drop can also be a concern when transferring the typical 5V and 3.3V power supplies over long cables.

Some examples of applications requiring long distances include smart building systems, room and desk booking systems, industrial machines with the display on an articulated arm, and remote-control panels for machines and devices.

Figure 1: The IDP modules are ideal for use cases where there is distance between the HMI and the main system controller

The Intelligent Display Panels (IDP) from Bridgetek provide a robust solution allowing the graphical touch display to be located at greater distances from the main system MCU or controller. They connect via half-duplex RS485 allowing long-distance communication over a low-cost, compact and flexible cable as well as communication on a bus with multiple external devices. A single cable (for example CAT5e network cable) carries both data and power.

The IDP module is powered from a nominal 24V supply, which reduces the current, and provides more headroom for voltage drop over long distances. This supply is regulated and smoothed internally, providing stable 5V and 3.3V rails for the electronics inside. The module can only be powered via the RJ45 or JST connector (depending on model) and so a PoE injector can be used to connect a 24V power adapter to the RJ45 connector.

Note that the IDP-3510-04A desktop module connects via Wi-Fi and Bluetooth and is powered by a local USB Micro-B 5V power adapter.

System Architecture and Partitioning

The IDP modules also help designers add a graphical touch HMI to products and systems where the main product controller does not have an MCU. For example, this may be an industrial controller which communicates over RS485 but does not have an interface or a software system which can be programmed to control EVE directly.

There are also cases where a product may not be able to accommodate changes. The MCU or processor used may be running very tightly timed control loops, may be at its maximum capacity already in terms of resources, or may have very basic I/O or programmability. It is also possible that the main controller software cannot be changed for certification purposes or that the controller is an accessory for a 3rd party product which has an available UART or RS485 interface.

The IDP modules offer a solution as a self-contained module. The on-board MCU (FT900, RP2040 or ESP32 depending on model) allows the IDP module to take care of the HMI tasks and implementation, via the EVE device, ensuring a responsive experience for users. It runs the custom HMI design which can be developed via our graphical design tools and BSPs (board support packages).

Figure 2: The IDP modules feature an EVE graphics controller and on-board MCU. Note that the peripherals shown vary by model – See Figure 5 for details.

The MCU also facilitates the connection of the IDP module to external devices via an RS485 link (or Wi-Fi and Bluetooth on the IDP-3510-04A). The RS485 communication is fully managed by the onboard MCU, allowing either the use of a standard protocol such as Modbus or the implementation of a custom protocol defined by the developer. The IDP module manages the user interface, receiving commands and data updates via RS485 and sending commands based on user interactions with the HMI. It can therefore be easily tailored to match the requirements of the attached RS485 device(s).

Time to Market

Time to market is another key factor which can challenge designers. Whilst devices such as EVE help keep the BOM and PCB space to a minimum when adding graphical touch display to a product, the design of the enclosure itself along with mounting of the display, PCB and external connections, can be complex and time-consuming.

The IDP modules are supplied in a modern and stylish custom-designed enclosure providing fast and easy integration into products, mounted within buildings or even positioned on desks etc. They are available with display sizes from 3.5” up to 10.1” to suit a range of applications.

Figure 3: The IDP-3510-04A is ideal for rapidly deploying devices for use on desktops etc.

Figure 4: The IDP-1000-04A provides a large 10.1” display with capacitive touch and a range of mounting options

Features of the IDP Modules

The IDP modules also have a range of peripheral devices onboard (depending on model) which can enhance the functionality and the user experience as shown in the table below. Please also refer to the individual IDP module datasheets for more details.

| IDP Module |

|

|

|

|

|

|

|

| Display size and resolution | 3.5”

320 x 480 |

3.5”

320 x 240 |

4.0”

480 x 480 |

5.0”

800 x 480 |

7.0”

800 x 480 |

7.0”

800 x 480 |

10.1”

1280 x 800 |

| EVE Device | FT811 | FT813 | BT815 | FT813 | BT815 | BT815 | BT817 |

| Touch | Capacitive | None | Capacitive | Capacitive | Capacitive | Capacitive | Capacitive |

| MCU | FT903 | ESP32 | RP2040 | FT903 | FT903 | FT903 | RP2040 |

| Data Interface | RS485

(RJ45 x 2) |

Wi-Fi, Bluetooth, Bluetooth LE | RS485

(JST connector |

RS485

(RJ45 x 2) |

RS485

(RJ45 x 2) |

RS485

(RJ45 x 2) |

RS485

(JST connector |

| Power | 24V

(9 – 24V) |

5V

Micro USB |

24V

(15 – 24V) |

24V

(9 – 24V) |

24V

(9 – 24V) |

24V

(9 – 24V) |

24V

(9 – 24V) |

|

Other Features

|

Smart LED indicator

Audio buzzer ID switch |

USB-UART interface

Smart LED Indicator Audio buzzer User-defined function button |

Audio buzzer

ID switch |

Digital microphone

Ambient light sensor Smart LED indicator Audio buzzer ID switch |

Digital microphone

Ambient light sensor Smart LED indicator Audio buzzer ID switch |

Digital microphone

Ambient light sensor Smart LED indicator Audio buzzer ID switch 13.56MHz RFID Reader |

Time-of-Flight sensor

Ambient light sensor Smart LED Indicator Audio buzzer ID switch |

| Enclosure form factor | Portrait display for wall and panel mounting

|

L-Shaped desktop display | Sleek and modern design for wall and panel mounting

|

5” landscape display in enclosure for wall or panel mounting | 7” landscape display in enclosure for wall or panel mounting | Version of IDP-7000-04A with RFID Reader | Large 10.1” display with sleek and modern design for wall and panel mounting |

Figure 5: Comparison of the IDP modules

Audio Buzzer: Allows the application to play sounds (either built-in or custom sounds converted using the EVE Asset Builder). Play clicks or beeps to acknowledge touch inputs or a range of sounds as notifications and alarms to get the users attention.

Ambient Light sensor: The MCU can use this to sense the ambient light levels which the display is exposed to. It can then adjust the display backlight brightness (via the internal EVE device’s backlight PWM output) to an optimal level for viewing.

Time of Flight sensor: Allows the MCU to detect when a user is in close proximity to the display. The display can be put into a low-power mode when no user is present for a certain amount of time and can be woken up when they approach. This can save power and increase life span by avoiding the display being on when no users are present.

Smart LED indicator: One or two RGB LED light strips integrated into the enclosure, with full control of the colour from the MCU, can be used to provide at-a-glance status indication to users from a distance even when the display is off.

RFID Reader: The integrated reader can be used for user identification and access control, etc.

ID switch: A rotary switch provides a convenient way to set a unique ID or address for each unit and can be read by the firmware on the internal MCU. For example, this can be used to set a unique ID where a number of the IDP panels are used on the same RS485 network.

User defined button: This button on the IDP-3510-04A is read by a GPIO input on the MCU and can be used as a function button by the firmware for accessing various settings, including display functions, brightness adjustment, volume control, and factory reset.

RJ45 in/thru: Some models have RJ45 connectors for both RS485 and power. Two connectors are provided, which are linked inside the IDP, allowing easy daisy-chaining of the panels for systems where multiple display panels are used. Other models have a single JST connection with 5M JST to RJ45 provided.

Capacitive Multi-Touch: Available on all models except IDP-3510-04A, the displays have touch panels supporting up to 5 simultaneous touches, allowing the application to use touch control. The EVE touch engine makes firmware development easy with its tagging and tracking features.

SD Card: The SD card is connected to the MCU. The application code can read files such as bin files containing assets for the user interface (such as images).

Digital Microphone: This allows the MCU to capture audio vis the microphone on the side of the enclosure.

Application Development

Bridgetek’s range of free tools and examples combined with the powerful on-board EVE graphics controller allow comprehensive and capable HMIs to be created and deployed rapidly for the IDP modules.

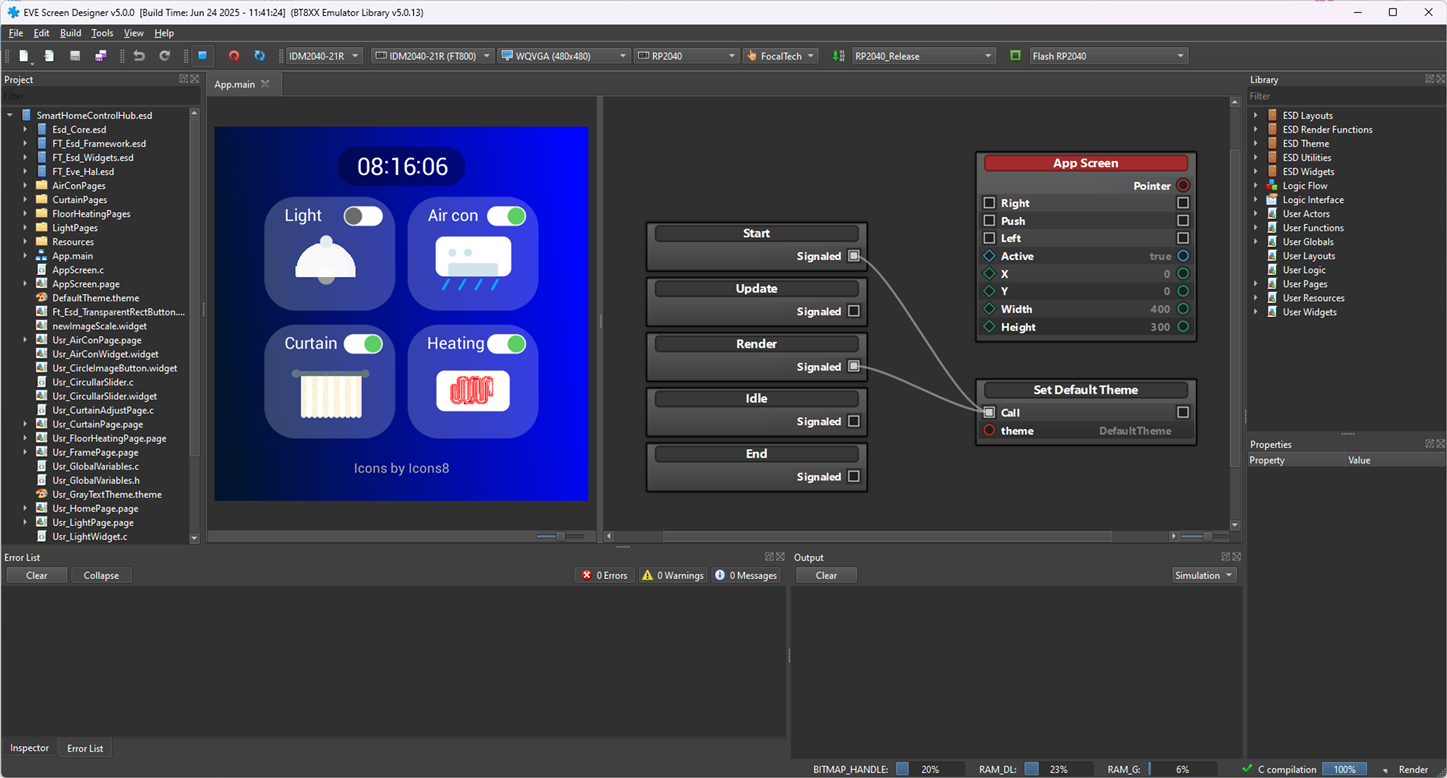

The EVE Screen Designer offers drag-and-drop layout of the screen content with a wide range of widgets and controls, in addition to the logic to handle user inputs and update the display. The IDP modules can be selected as the target device when creating a new project and the code can be easily deployed to the MCU.

Figure 6: Software development is fast and easy with the EVE Screen Designer

Alternatively, developers may build the application using a code-based approach by leveraging the Board Support Package (BSP) for each module, which is accessible via the Bridgetek GitHub repository. The BSP includes drivers for the different hardware devices onboard, allowing developers to avoid the time needed to create hardware drivers etc. and begin developing the main application immediately.

Figure 7: BSPs for each module save time and effort to speed application development

Applications

Applications include:

Conclusion

With the new IDP modules from Bridgetek, designers can quickly and easily enhance the way that users interact with their product. Tasks such as mechanical enclosure design, and creation of code libraries for bespoke hardware designs often add significant delays to a project. The IDP modules help engineers avoid these delays, saving time in application development and going to production.

The modules also provide a reliable solution where the there is a large distance between the display panel and the device that it is controlling, or indeed in systems where the main processor cannot accommodate a graphics library and SPI / QSPI connection directly.

Some of the key features of the IDP modules include:

The IDP modules are ideal for engineers designing and updating in-house products, design consultancies, and companies developing 3rd party controls for other products and systems.

Introduction

The ambition to create the optimal HMI (Human Machine Interface) has been a driving force for creators and designers, since the advent of automated devices, and is today as important as ever. Users interacting effortlessly with intuitive products is vital for success in an ever-competitive marketplace.

One of the most flexible and effective approaches is to add a graphical touch interface to the product’s existing MCU. This is made easy with Bridgetek’s Embedded Video Engine (EVE). Software developers then have a comprehensive collection of widgets and controls at their fingertips to create and optimise the User Interface (UI).

However, for some applications, supplementing the benefits of graphical touch interfaces with tactile mechanical controls provides an even better solution, but results in added complexity and longer time to market. But fear not, the IDM2040-21R module from Bridgetek is here to help…

Challenges

· Applications which require a more tactile user experience – It can be beneficial, or indeed necessary, for users to interact with the product without visibility of the display. Or in some specific applications, the original design selected a rotary control to provide the most natural and intuitive interaction. In these cases, touch display controls alone may not provide the complete user experience.

· Maintaining usability as the product feature set grows – Updated products and new designs often have a much greater range of features. Enabling user interaction with these in the same product form-factor or panel space, can be very challenging without compromising usability.

· Mechanical design, manufacture and time to market – Incorporating tactile features in an aesthetically pleasing shape, size and form-factor can help make the product much more effective, but designing and producing the mechanical components for volume production can be challenging and significantly delay time-to-market.

Solutions

· Tactile interaction with the IDM2040-21R’s rotary dial with push function – The IDM2040-21R enhances the user experience, by combining a rotary dial with pushbutton around a central circular touch display.

· Maximise useability with the IDM2040-21R’s 2.1” circular colour touch display – With the graphical touch display featured on the IDM2040-21R, you can easily support a wider range of product functions in the same form factor as an original rotary dial control or gauge

· Fast time to market with the ready-made IDM2040-21R module – Integrating the IDM2040-21R into a final product avoids the time-consuming development, test and volume manufacture of a custom module with display and rotary dial functionality.

Applications which require a more tactile user experience

Whilst many solutions require designers to choose between tactile operation and the benefits afforded by graphical touch displays, the IDM2040-21R provides the best of both via the rotary dial with push button, and graphical touch screen via Bridgetek’s FT800 Embedded Video Engine.

The rotary dial is well suited to applications such as audio or smart home applications (and many more), providing a natural interaction. The rotary encoder detents provide tactile feedback as it is rotated, with the integrated pushbutton allowing easy selection. The encoder and switch are read via the on-board RP2040 MCU’s GPIOs allowing the designer to define how it interacts with their UI. For example, the dial can be used to cycle through pages or menus on the display and to adjust a parameter on the desired page.

With the IDM2040-21R, a rotary dial further enhances the user experience, supplementing the graphical touch display

The graphical display’s touch panel is also easy to program thanks to the FT800’s touch engine. Bridgetek provide a binary file which can be loaded into the FT800 from the RP2040, allowing it to communicate with capacitive touch panels. The application can then benefit from EVE’s touch tagging and tracking features which make programming of buttons and sliders simple and help improve the user experience.

The optional audio output from the FT800 can also be used to provide an even more tactile experience by acknowledging turns on the dial, touches on the screen or sounding alerts to get the user attention. The FT800 has a range of built in sounds as well as the ability to play custom sounds converted with our free software tools.

Maintaining usability as the product feature set grows

As products evolve, their feature set often grows significantly. The UI designer must provide access to these without compromising useability, and in these cases the flexibility of a graphical touch screen is invaluable. The product can retain the original form-factor, using multiple pages, menus and graphical representations such as icons and charts to present a lot of information in a small space, something which is otherwise very difficult to achieve.

The IDM2040-21R’s circular graphical touch display allows complex devices to be controlled without compromising on ease of use

With the IDM2040-21R’s 2.1” 480×480 pixel circular touch screen, designers can produce intuitive, yet highly functional UIs tailored closely to the product and user needs. The on-board FT800 Embedded Video Engine combined with powerful software tools, available free of charge from Bridgetek, make it fast and easy to incorporate menus, icons, images, branding/themes, fonts, different languages, and more…

For example, with EVE Screen Designer (ESD), the designer can drag and drop a diverse set of built-in and custom widgets to create the UI, as well as creating the application code via the graphical flow editor. User code can be added, for example to read I2C sensors via the RP2040 or to communicate with a smart home system via the serial interfaces. The UI can be simulated within the ESD tool itself on the computer monitor, before building the code to be programmed into the RP2040 on the IDM2040-21R itself.

With Bridgetek’s EVE Screen Designer and code examples, designers can create attractive and intuitive UIs in a short time

Mechanical design, manufacture and time to market

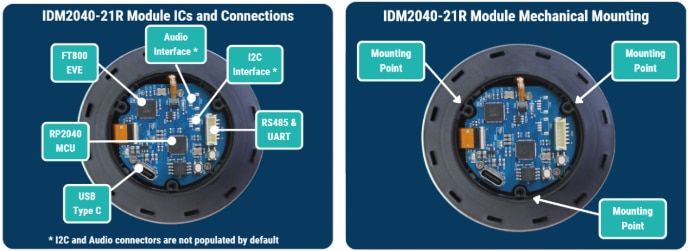

When designing a control device that combines mechanical inputs with a touch screen, there are many aspects which take significant time and resource, especially when preparing for volume production and test. The IDM2040-21R provides a ready-made solution, with the enclosure, rotary dial and pushbutton mechanism integrated, circular colour screen and touch panel, as well as a PCB with integrated FT800 and RP2040 MCU.

The key components and architecture of the IDM2040-21R

When incorporating the module into an overall product, the on-board RP2040 can communicate with the rest of the product via UART and RS485. UART is well suited to short connections (for example if the IDM2040-21R is in the same enclosure as the rest of the system) whilst RS485 uses the same data protocol but allows longer distances (for example to a smart home network over tens or hundreds of metres).

The I2C interface allows the RP2040 to be interfaced to sensors and other devices (for example local temperature measurement or ambient light level). The audio connector allows the audio out from the FT800 to be connected to an external speaker. This is an audio level signal and so requires an external amplifier to drive a speaker. Note that the connectors (CN3 for I2C and CN6 for audio) are not populated by default but the connector part BM04B-SRSS-TB can be added. The additional USB interface allows easy programming of the firmware to the RP2040-21R.

Integrating the IDM2040-21R to a product or system is fast and easy

Mechanically, the module can be securely integrated via three screws on the rear of the enclosure to the chassis inside the product or system.

Conclusion

When striving to create HMIs which provide an optimal user experience, designers must provide visibility and control of a much larger set of product functions and features, whilst ensuring elegant aesthetics and usability.

The addition of a graphical touch display can provide an ideal solution, with devices such as the Bridgetek EVE helping to ease integration and reduce development time. However, there are some cases where adding more tactile control via a rotary dial can enhance the user experience.

The IDM2040-21R module helps designers achieve this, and can be used directly in final products, providing a ready-made solution which offers a great user experience without time-consuming and complex development.

· Aesthetically pleasing design with tactile user feedback

· Avoid complex mechanical rotary dial design and manufacture

· Ready-made electronics assembly with encoders, touch display, FT800 and MCU

· Save UI development time with comprehensive tools and examples

· Simple hardware and electronics interfacing to the final product

The IDM2040-21R is ideal for a wide range of applications including Smart Building controls, Audio devices, Vehicle gauges, Industrial pumps or fan controllers, and many more. Looking to create UIs that enhance your product’s user experience, with a short development cycle and fast time-to-market? It’s Easy with EVE! Get in touch with us to find out more about our IDM2040-21R!

Find out more at these links:

IDM2040-21R module product page

Engineers are all too familiar with the challenges involved in achieving true excellence in their design whilst getting it to market in time. As a defining factor in the user experience of the product, the Human Machine Interface (HMI) is one area where this increasingly holds true.

Whether creating new products or updating existing designs, the addition of a Graphical User Interface (GUI) is one way to improve the user experience significantly. Vital steps in the development process (including evaluating and selecting the right graphics controller, prototyping, GUI development and preparing for mass production) must be thorough but efficient to achieve commercial success. Reluctantly, compromises are often needed to achieve this. With the right solution however, you can achieve great products and fast time to market.

Challenges

Some of the key challenges facing engineers during the product development cycle include:

Solutions

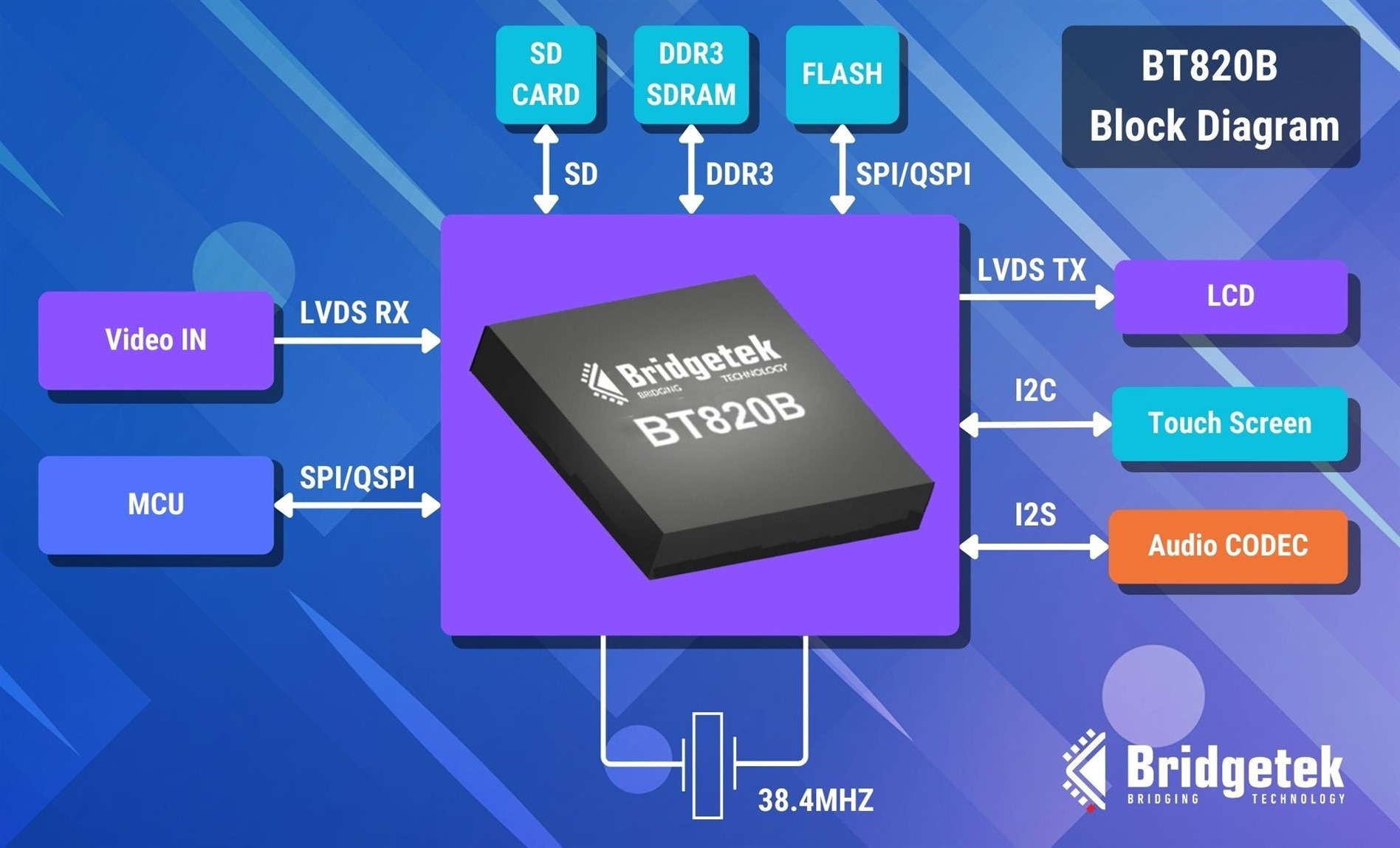

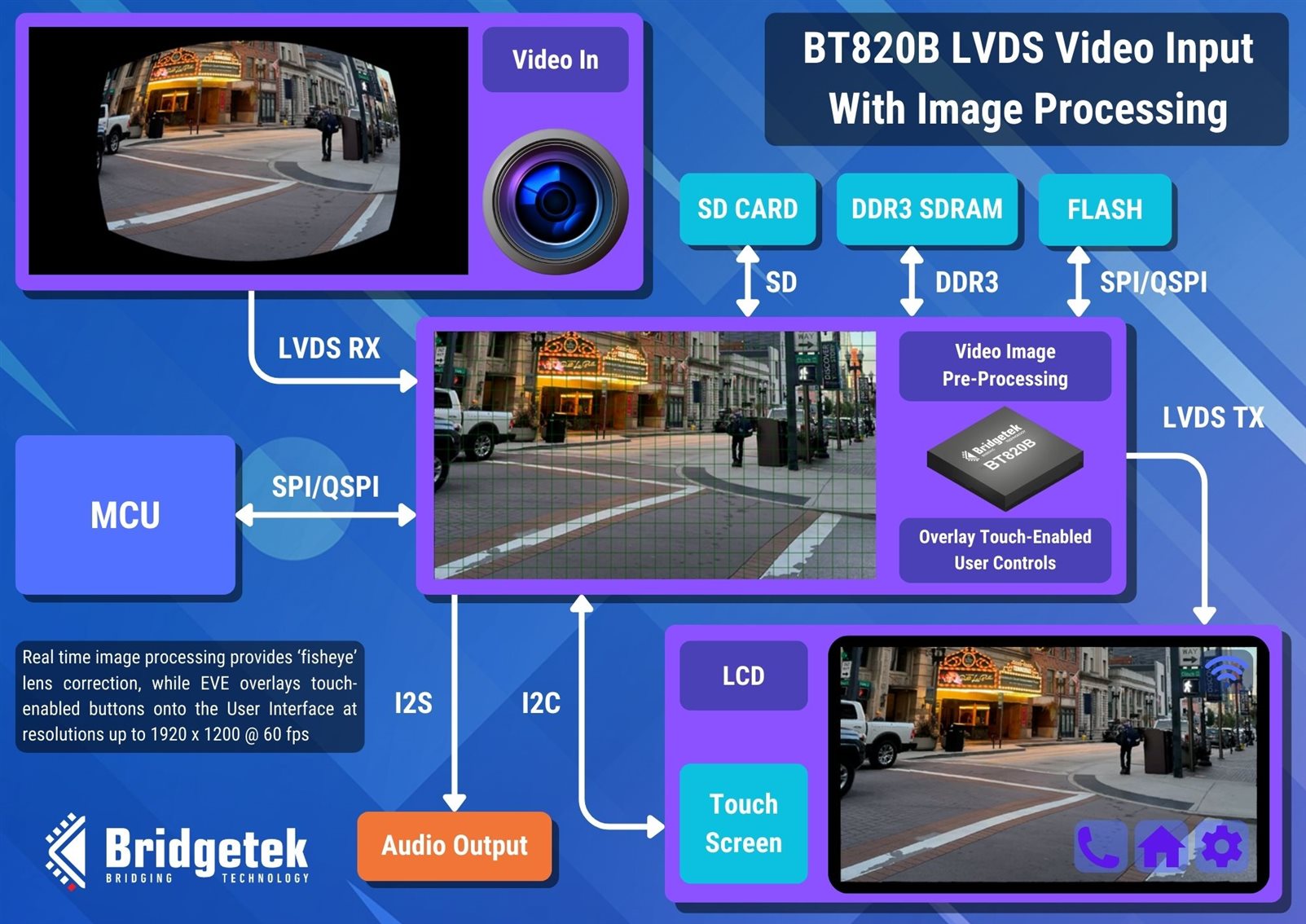

The BT820B: A powerful yet easy-to-use GUI Solution for any MCU

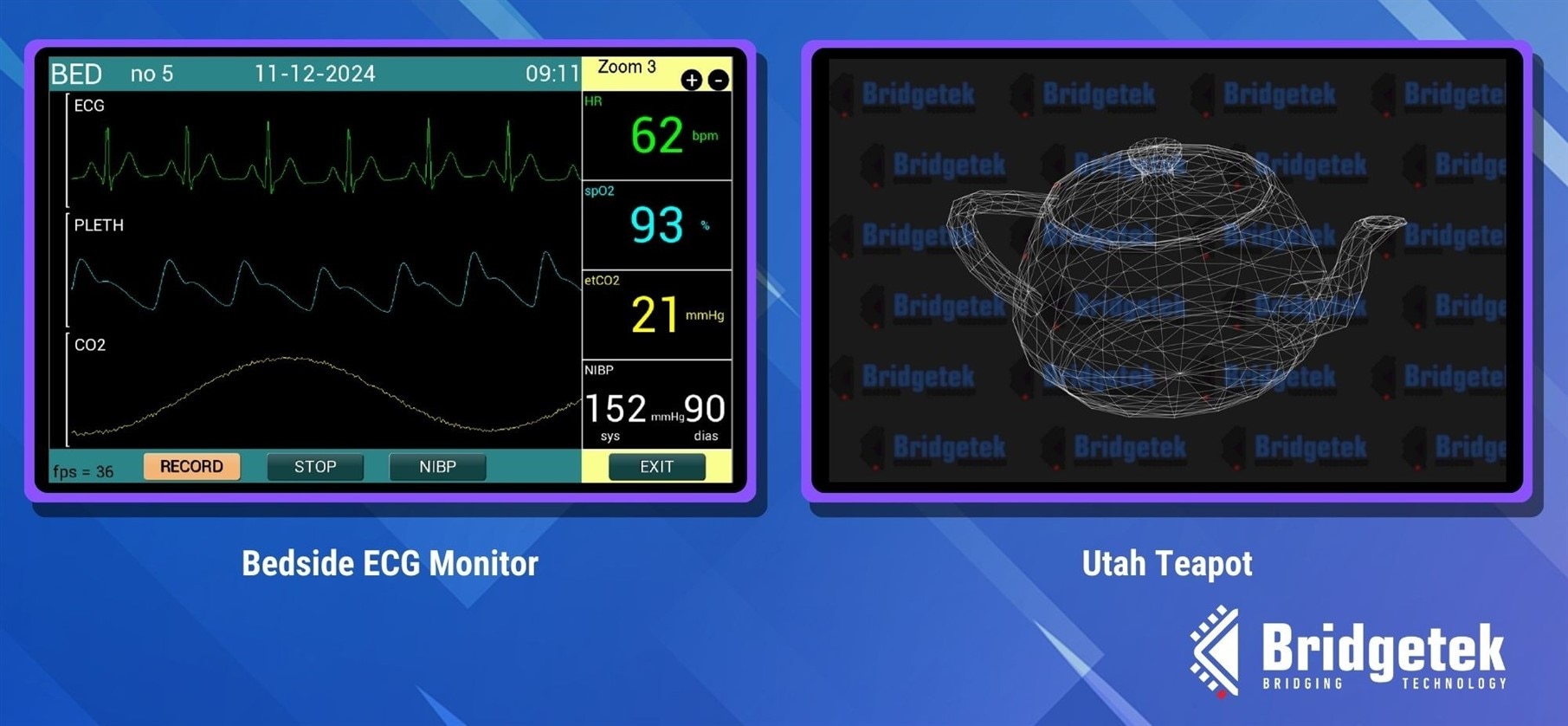

The BT820B Embedded Video Engine (EVE) IC offers a 3-in-1 solution for adding three key GUI features to any MCU: high resolution graphics, touch screen control and audio output. Capable of driving LVDS displays up to 1920 x 1200 pixels (for example 15.6” displays) at up to 60 frames per second (fps), it provides an ideal platform to create feature-rich GUIs which meet and exceed users’ expectations in fields such as industrial control, medical instruments, transportation, and building automation applications.

With EVE, designers have an alternative to MCUs with on-board graphics capability when developing products which use a GUI. Instead, they can select any MCU based on the requirements of the product, with only an SPI/QSPI Master being required to interface with EVE. By eliminating the move to a more complex MCU, engineers benefit from time savings through re-use of existing application code and avoiding the hurdles in becoming familiar with a new MCU platform and associated tools.

Key features of the BT820B Embedded Video Engine used on the MN820 Mini Module

Key features of the BT820B Embedded Video Engine used on the MN820 Mini Module

What’s more, EVE’s innovative and unique features like the touch engine, audio engine, directly attached Flash storage and real-time video input with pre-processing minimise the workload and Flash memory requirements on the MCU. This enables a cost-effective MCU to be selected and accelerates the application development process without compromising on GUI functionality.

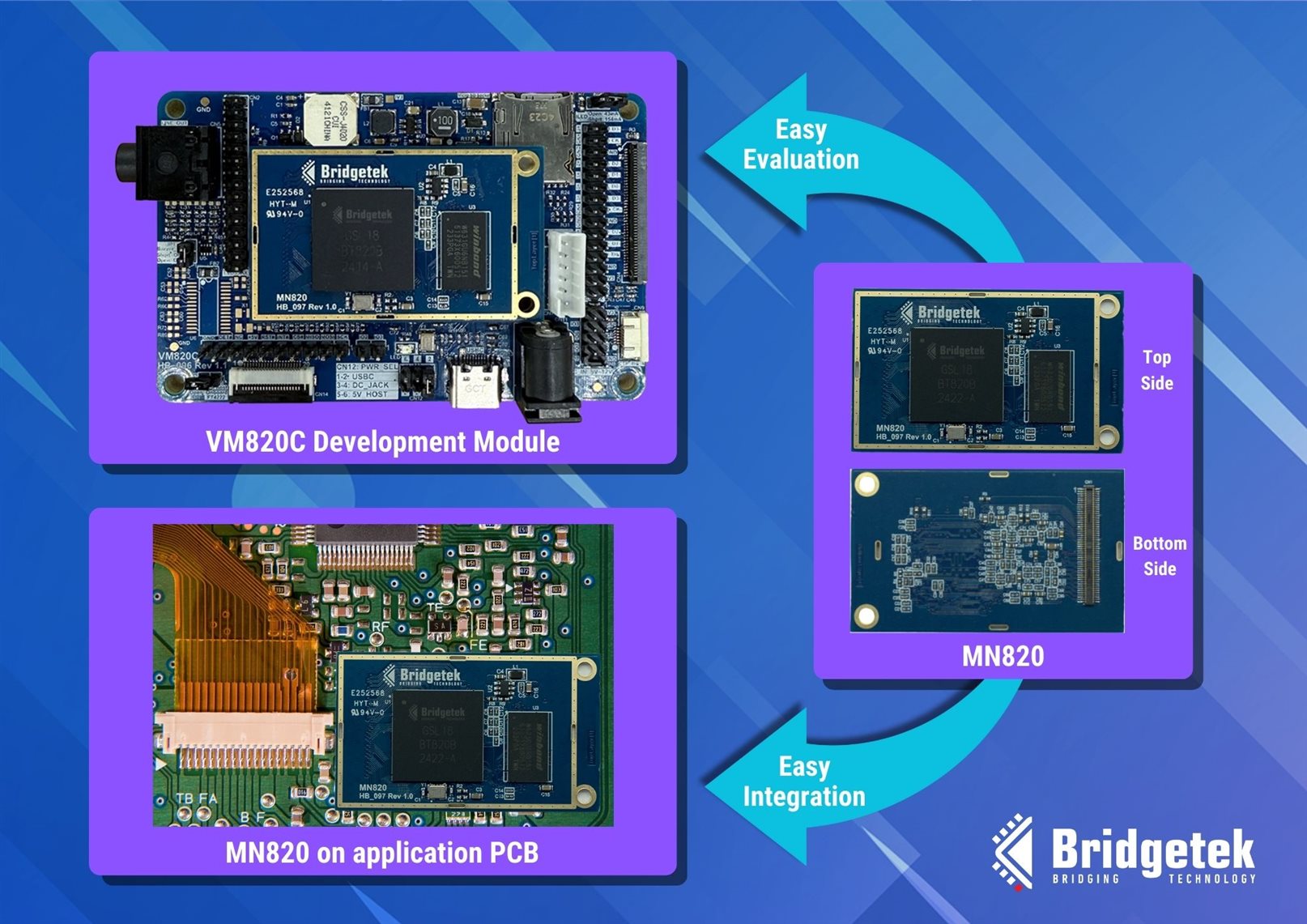

The VM820C proposes a fully featured BT820B evaluation setup ready within minutes. At the heart of the VM820C lies the MN820 Mini Module with its on-board BT820B and 1Gbit DDR3 SDRAM. An extensive range of connectors on the VM820C allows fast and easy access to all the BT820B’s features and interfaces. Simply connect an LVDS display and I2C touch cables to get started. You can also connect speakers for stereo audio and a live video input to LVDS Rx.

The VM820C (with on-board MN820) provides convenient connections to all interfaces on the BT820B IC

Begin by downloading the free toolchains and examples. The emulation features of the EVE Screen Designer (ESD) and EVE Screen Editor (ESE) allow you to begin designing even before you have hardware. Attaching the VM820C hardware to your computer via USB (with its on-board USB-QSPI interface) then allows you to preview your GUI on a real display and to run our extensive range of examples.

As the application development progresses, simply connect the same VM820C to your chosen MCU (via the SPI/QSPI pin header), import the code for your GUI to your MCU’s toolchain environment, and continue development of your application.

It is vital, when selecting a solution at the beginning of the project, to ensure that it is feasible for mass production. Larger high-resolution displays and more extensive GUIs expected by users often require more powerful graphics solutions, with frame buffers in external RAM and high-speed data interfaces such as LVDS and DDR3. These bring more stringent routing requirements and design constraints compared to previous generation graphics devices, which can increase the engineering effort and tools required to complete the design.

Recognising this challenge, Bridgetek introduces the MN820 Mini Module as part of the launch of the new BT820B Embedded Video Engine, giving designers a powerful solution for creating stunning GUIs and a simple PCB design at the same time. After prototyping and development, designers can easily adopt the MN820 on their production PCBs by placing a 100-pin board to board connector.

Take advantage of the MN820’s hardware features to simplify the final product PCB design

Incorporating the BT820B IC itself and 1Gbit of DDR3L SDRAM, the MN820 takes care of the most challenging parts of the hardware design, including BGA package routing, decoupling and assembly, and the timing-critical DDR3 traces. The on-board DC-to-DC step-down converter allows a single 3.3V supply to be used, further simplifying the main product PCB. With its small footprint, at only 49mm x 29mm, the MN820 can be easily integrated into the product PCB as an alternative to the BT820B IC itself.

When adding a GUI to a new or existing product, Bridgetek’s innovative solutions help engineers with all aspects of the project from initial development through to mass production.

The BT820B IC empowers designers to create high-resolution high-performance GUIs. Significant time and cost savings can be achieved via easy integration to their preferred or existing MCU, compared to re-designing with a complex graphics MCU.

Extensive development support, in the form of hardware modules such as the VM820C and software tools and examples, ensures that high quality GUIs can be created quickly and easily.

Offering an alternative hardware solution to integrating the BT820B IC itself on the product PCB, the MN820 Mini Module allows designers to continue this momentum to bring products such as building access controllers, medical devices, test and measurement devices, or instrumentation with high-resolution feature-rich GUIs to production in a short timescale.

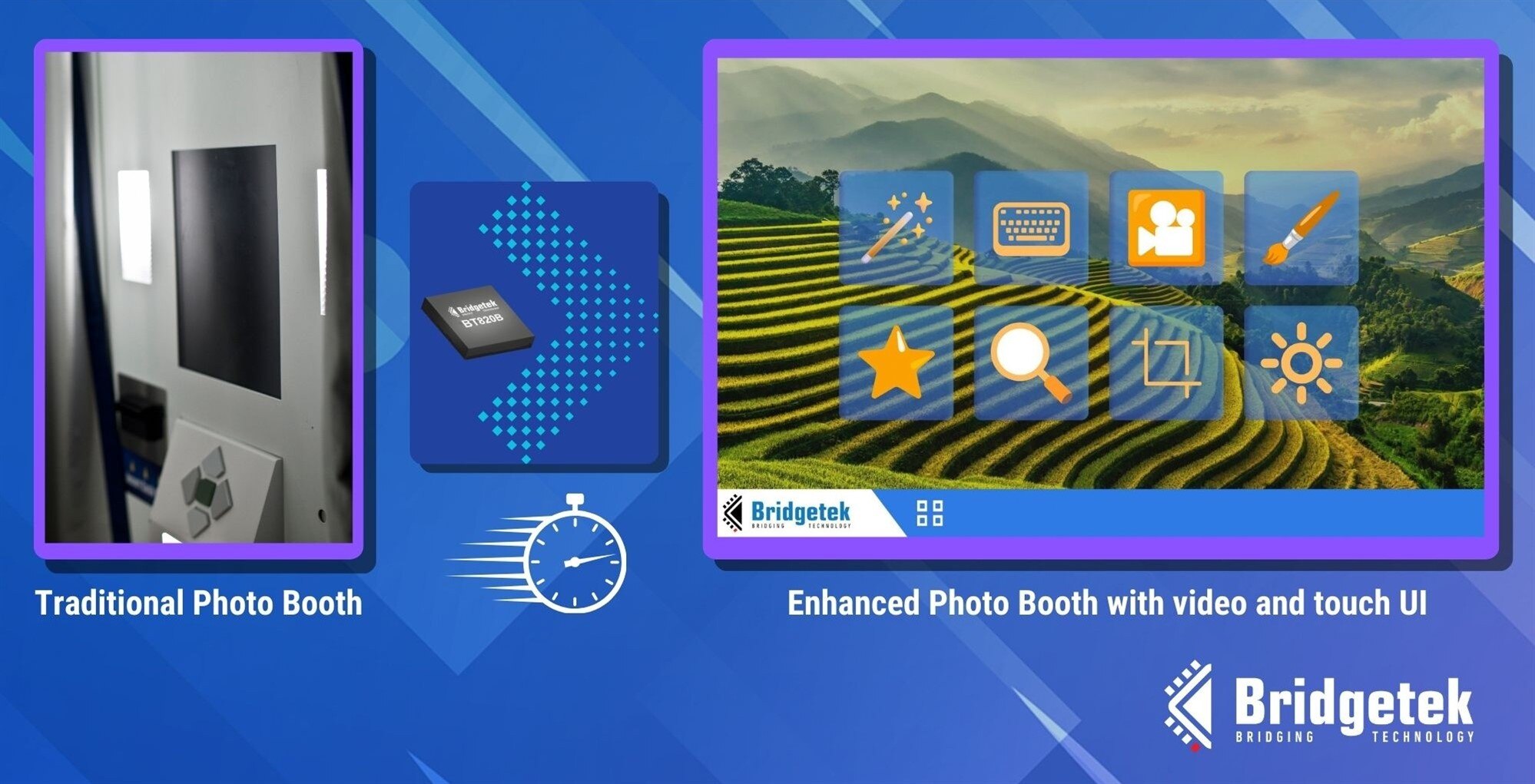

Bridgetek is excited to announce the launch of our BT820B, the 5th Generation Embedded Video Engine (EVE), at the Embedded Exhibition in March 2025.

The launch includes our BT820B IC, as well as a range of development modules and supporting software toolchains. As industry trends lean towards larger displays with more complex User Interfaces (UI), it often involves a requirement to incorporate live video streaming too.

The BT820B’s enhanced features and capabilities provide designers with an effective solution to implement these advanced UIs easily and get their product to market in a short time.

Bridgetek is excited to announce the launch of our BT820B, the 5th Generation Embedded Video Engine (EVE), at the Embedded Exhibition in March 2025.

The launch includes our BT820B IC, as well as a range of development modules and supporting software toolchains. As industry trends lean towards larger displays with more complex User Interfaces (UI), it often involves a requirement to incorporate live video streaming too.

The BT820B’s enhanced features and capabilities provide designers with an effective solution to implement these advanced UIs easily and get their product to market in a short time.

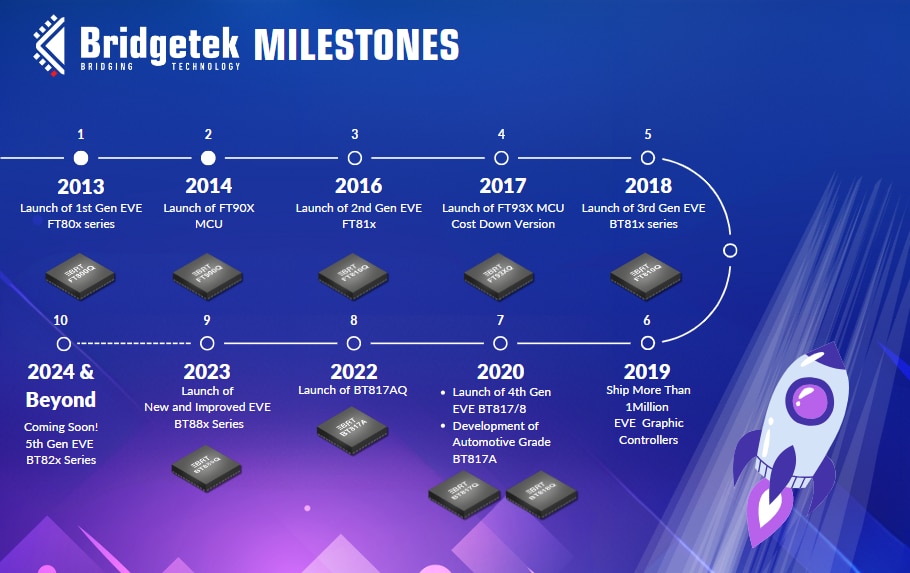

For the past decade, the innovative EVE products have empowered designers to enhance the way that users interact with their products. The first device in the EVE family, the FT800, brought a unique approach to adding graphical touch-enabled UIs to existing and new products.

Designers were no longer restricted to MCUs with built-in graphics, avoiding unnecessary costs, complexity, re-design effort, and excessive time to market. Instead, they could easily add three key functions (Display, Touch and Audio) to whichever MCU was the best fit for their product, benefitting from features such as:

Since then, the EVE family has continually evolved, enabling designers to meet and exceed the latest expectations of their product’s end-users and UI requirements. To find out more about our EVE family, check out our Getting Started page.

As the capabilities and feature set of products increase, designers must support these in the UI whilst meeting growing expectations from users on the look, feel and ease of use. Three notable challenges which designers looking to embrace the latest UI trends face are:

Increasingly complex user interfaces require designers to look for more powerful graphics solutions without compromising ease of development and time to market

Combining live video with a touchscreen improves the user experience but is hindered by complexity and performance limitations in many display solutions

When updating and designing products with advanced user interfaces, ease of integration is vital in getting the product to market

Addressing these challenges is essential to allow designers to keep their product ahead of intense competition, but without the right tools and solutions, they present significant obstacles.

With the BT820B, designers get all the benefits of our earlier EVE devices but with powerful capabilities and enhanced feature set to help them achieve stunning UIs that will impress users and set their product apart from competitors.

Key features of the BT820B

The BT820B frame buffer architecture, combined with extensive storage and image formats, handles complex user interfaces with ease of applications such as medical equipment

The BT820B frame buffer architecture, combined with extensive storage and image formats, handles complex user interfaces with ease of applications such as medical equipment

The BT820B’s innovative touch tagging and tracking features allow designers to integrate UI control functionality on-screen with ease, while the wide range of capacitive touch controllers (CTP) supported allows designers the freedom and flexibility to choose the best touch panel for their application.

The BT820B features stereo audio output (via digital I2S or analogue Delta-Sigma PWM) in place of the mono output on earlier EVE devices. It also supports direct playback of .wav files. The enhanced audio engine allows sound generation and playback features to be easily incorporated into the end-product.

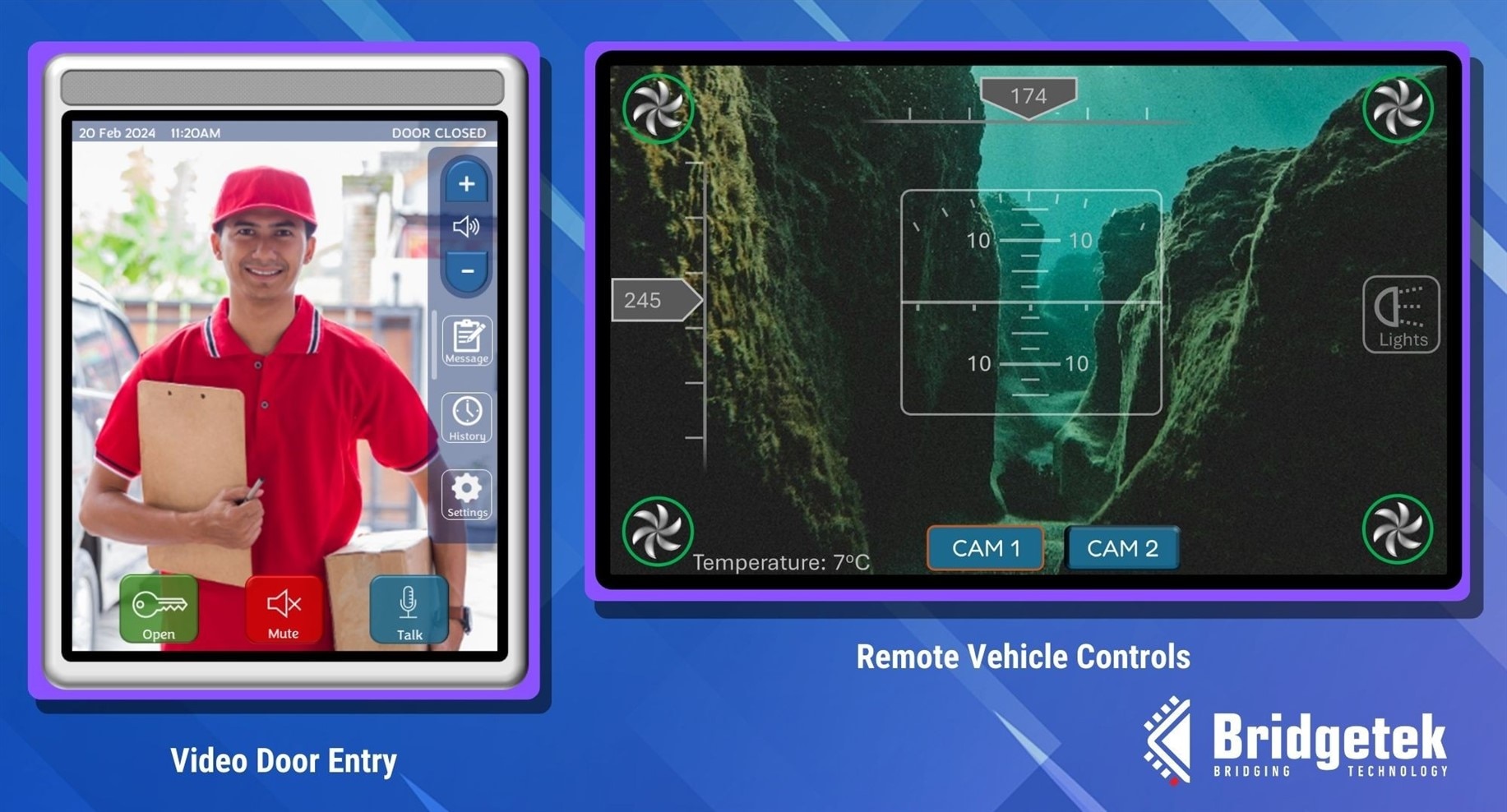

The BT820B supports direct video input and overlay of touch controls. Real-time video image processing provides image enhancement for applications such as video door entry and vehicle cameras.

The VM820C board and MN820 mini-module provide a rapid development solution for designers. The MN820 can also be used in final products to simplify the PCB design.

The VM820C board and MN820 mini-module provide a rapid development solution for designers. The MN820 can also be used in final products to simplify the PCB design.

Bridgetek launched the Embedded Video Engine (EVE) with the first generation, FT800, in 2013. Graphical touch screens were revolutionizing the way that users interact with all kinds of everyday devices, but designers were facing challenges in implementing them. Existing approaches to adding these interfaces to products were complex, expensive, and involved significant re-design, often requiring a change to a high-end MCU.

Bridgetek EVE’s Milestones

Bridgetek EVE’s Milestones

With EVE, designers can add three key functions (Display, Touch and Audio) to their product using a single IC connected via SPI, retaining the product’s existing MCU. For new designs, they can select an MCU best suited to the product function without being limited to those with built-in graphics support. Innovative features of the EVE family include:

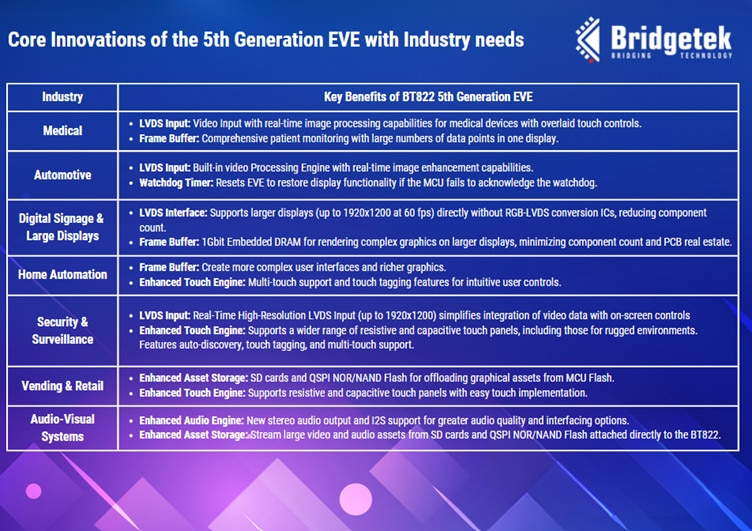

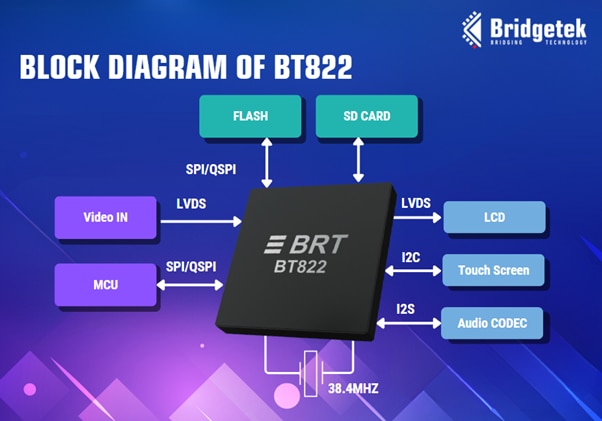

Today, Bridgetek is thrilled to announce the launch of the BT822, the 5th Generation Embedded Video Engine (EVE) device, which continues to revolutionize the use of color touch displays.

Over the past decade, expectations for user interfaces have increased significantly, with the evolution of the EVE product line allowing designers to embrace the latest trends. Some of the most recent challenges include:

To support the latest demands, the BT822 features a redesigned architecture which also boasts significant enhancements and new features that allow designers to meet and exceed the modern user interface expectations. One key objective was also to retain the characteristics which made EVE popular originally.

This new generation offers enhanced display resolution up to 1920×1200 via LVDS output, a new Frame Buffer architecture, an LVDS video input with real-time image processing engine, support for SD/MMC storage options and enhanced touch engine.

Block diagram of the BT822

PanL PD100 Display Screen 10.1” showing vibrant colours and graphics with UI-friendly icons (BRT Systems PanL Smart Living)

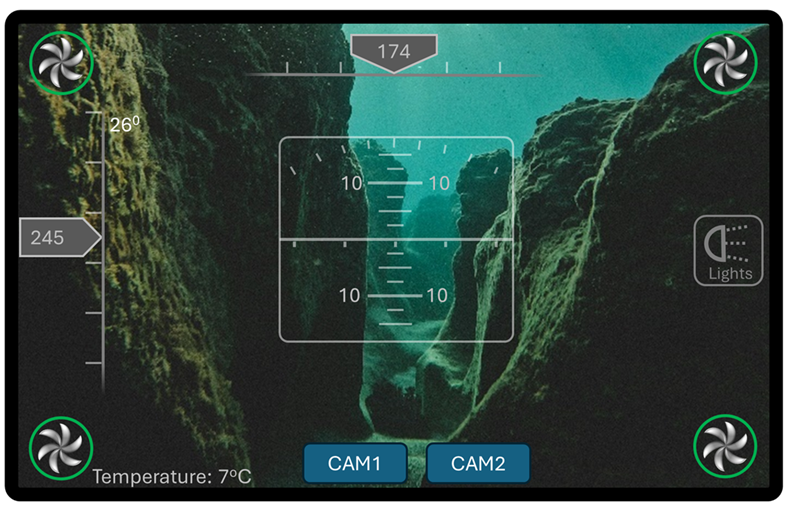

Remotely Operated Underwater Vehicle with Live Video Streaming

Remotely Operated Underwater Vehicle with Live Video Streaming

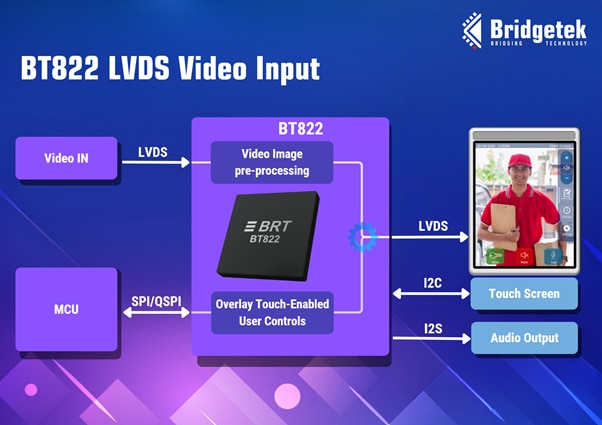

Direct video input with real-time pre-processing -> ideal for Door Entry applications

Direct video input with real-time pre-processing -> ideal for Door Entry applications

Summary of Benefits by Industry and the type of Core Innovations the BT822 delivers for your product design