Welcome to the NI (now part of Emerson) page on element14.

Emerson delivers future-ready test and measurement solutions through the power of the NI platform—a combination of high-performance open software, modular hardware, and AI-driven capabilities that enhance productivity. Flexible and scalable, the NI platform transforms how engineers automate measurement, control, and testing of complex products that move our world forward.

We’re excited to invite you to NI Days Italy 2026, our flagship event returning to Milan on March 11, 2026 — now expanded to 1.5 days of immersive learning, discovery, and connection / a full day of immersive learning, discovery, and connection.

Save the date and register now to secure your spot, seats are limited and innovation awaits!

Productivity in test has changed, and faster isn’t enough anymore. The new standard of productivity is built on intelligence, trust, and system-level insight. In this issue of The Edge, we explore how AI-assisted workflows, greener wireless optimization, and cybersecurity are reshaping modern test environments, and what it takes to lead in this next phase.

Read more: https://bit.ly/element14-theEdge

We’ve officially launched four cost-effective NI PXI hardware options to help more engineers accelerate automated test system development. It’s another step in our effort to reimagine productivity and ensure organizations stay future-ready with scalable test solutions. Learn more about the new PXI products: https://bit.ly/New-PXI-Newark

Our PXI platform is growing.

Soon more teams can build scalable automated test systems.

We are expanding our PXI portfolio with new PXI products that could make a real difference for your test setup.

Our webinar launch will introduce four new affordable products designed to help you:

• Scale efficiently for high-channel count applications without sacrificing performance

• Maintain seamless compatibility with your existing PXI infrastructure

• Streamline setup, development, and system-level debugging with NI software like InstrumentStudio, LabVIEW, and TestStand

You’ll also get access to live demos, expert insights, and new whitepapers during our upcoming webinar:

Scope It Out: 4 New Affordable PXI Products

January 21, 2026

11:00 a.m. CST

Join Our Guided, Hands-On LabVIEW Online Pilot Program

Curious about LabVIEW and how it can accelerate your test and measurement projects? We’re introducing a brand-new way to explore LabVIEW—and you’re invited to be among the first to try it!

No installations. No setup. Just you, your browser, and a fully hosted LabVIEW sandbox.

For three full days, you’ll have access to:

Your experience kicks off with a live, 90-minute expert-led session at 10 AM CST, featuring:

After the session, enjoy 3-day access to continue exploring LabVIEW at your own pace.

️ Space is limited to 25 participants per session—secure your spot today! Register here.

Be among the first to explore LabVIEW in a fully hosted sandbox pilot.

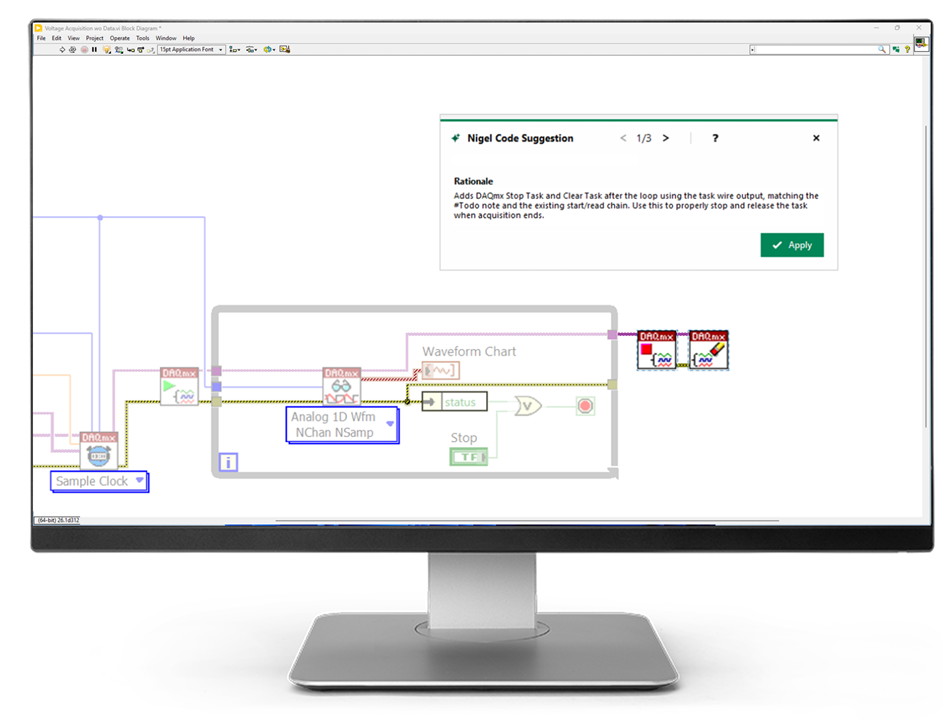

Join a free, expert-led session and get 3 days of hands-on access, including our new NI Nigel AI Advisor.

Your experience begins with a live, 90-minute session led by a seasoned test expert with over 25 years of experience.

You’ll dive into interactive demos, hands-on exercises, and get real-time answers to your questions—ensuring you leave with practical skills you can apply immediately.

Spots are limited - reserve yours now!

I'm super excited to announce that we are working with NI systems and integration partners to launch a series of technology focused webinars. Our first webinar is with Aliaro, who will provide key insights in to BMS testing.

The event is now officially launched and will be live on (UTC), sign up here:

Battery Management Systems: Testing and Simulation Explained

More dates to follow!

Please be gentle, this is my first post!

As part of my role within Farnell, I should have been more active on this community but I haven't as yet. Moving forward, I'm aiming to bring updates from both NI and Farnell including events, promotions, new product launches and more. As a starting point, here are some of the activities that I should have been shouting about...

Authorised Training Partner - Farnell UK

To start off, for the LabVIEW users out there, Farnell is an Authorised Training Partner. What does this means? If you're in need official NI training you no longer need to join virtual sessions or self teach. Come join us in our Leeds office on one of the dates below to be taught by a real, in person instructor. The team over at Control Software Solutions are on-board to provide instructors for all of our dates from their team of NI Certified Professional Instructors.

Nestled in that list are also certification exam dates! Same location, but because we will invigilate the exam, there is no need to jump through all of the hoops of the virtual examination delivered over the last few years. If your CLD, CLA, CTD, CTA, etc certification has lapsed and the thought of resitting remotely is putting you off, reach out and we can get you signed up.

ATP Certification Exams:

LabVIEW User Groups

Farnell is proud to support the engineering community, and as part of that we are supporting LabVIEW User Groups in the UK. These are local events, organised by engineers, for engineers. Each event typically has 3 or 4 speakers providing insightful talks based on something they've learned, best practices, new toolchains, etc. It's also a great place to hear from NI with updates on software roadmaps, releases, etc.

Following on from a strong start in January at the NWLUG, the rest of the year currently looks like this:

If I've missed any, let me know and I'll add them in and more details to be confirmed throughout the year too. Reach out to be included in the contact list for more information!

GDevCon

Following on from LabVIEW User Groups, GDevCon returns to the UK this September! GDevCon#6 is in Brighton from 9th to 11th September! This event is independently run and provides (probably) the best forum for all things graphical programming. Organised by leaders in the LabVIEW community, GDevCon is focused on delivering world-class graphical programming material covering a wide spread of topics relevant to today’s discerning developer.

NI Days

NI are bringing NI Days back to Europe!

So far this post has been UK centric, sorry about that. NI Days however, is a Europe wide series of events, where you can meet peers and key contacts within Farnell and NI to ensure you get the best support moving forward. Farnell will be attending all NIDays events in 2025 so sign up and stop by our stand to meet your local NI BDM! Events below with some details to follow:

Edit: Fixed some formatting and added images... everything looks better with pictures.

I heard about this job after we ran a roadtest on NI's Thermocouple Measurement Kit. I'm passing it on:

Who They're Looking For

What You'll Do

What You Need

How to Apply

My Take

If you are at all interested, I'd take the time to apply. My personal interactions with NI have always been positive. I've found them easy to work with. And their products have received good reviews. My feeling is test engineering is on a growth path, so it's an area that one should see career growth. Good luck.