Discover the world of sensors

Fundamentals

What is a sensor component?

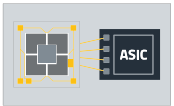

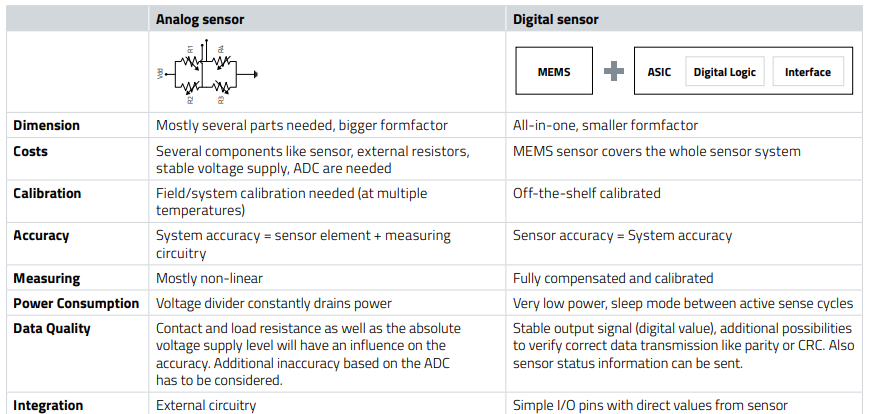

A system that measures a physical dimension and transfers into an electrical signal. Sensors are basically analog with infinite resolution, but data to and from the cloud is transferred digital. Analog sensor values must therefore be digitized. Conversion can be done in external AD converters when using an analog sensor cell or the conversion can be all done internally, within the sensor system, when using a MEMS sensor. Digital MEMS sensors help to save time, processor bandwidth and board space.

MEMS sensors

In a microcontroller the typical semiconductor can only control current and voltages. In a Micro-Electro-Mechanical System (MEMS), additional mechanical structures are used. This means that three-dimensional structures are usually added to the starting material silicon by etching processes. This allows the design of membranes (WSEN-PADS ) or movable finger structures (WSEN-ITDS ).

Combined sensors

Some sensors actually consist of multiple sensor elements in the same housing like the combined Humidity and Temperature sensor WSEN-HIDS or the combined Pressure and Temperature sensor WSEN-PADS .

This has advantages when:

- Space is at a premium (Diverse sensors in one housing require less space than single sensors)

- Power supply is limited (Multifunction sensors typically require less power than multiple single sensors)

- Price matters (a single, slightly larger, package is generally less expensive than several smaller ones.

- Measurement accuracy must be improved (Short cable runs between the contained sensors are more easily shielded within a package than connections made to the outside.

- Additional data can be calculated (in some cases, additional information can be calculated from measured values of combination sensors

Additional Advantages of integrated sensors

- Surface mounted device (SMD)

- Silicon based

- Fully calibrated

- Integrated DSP

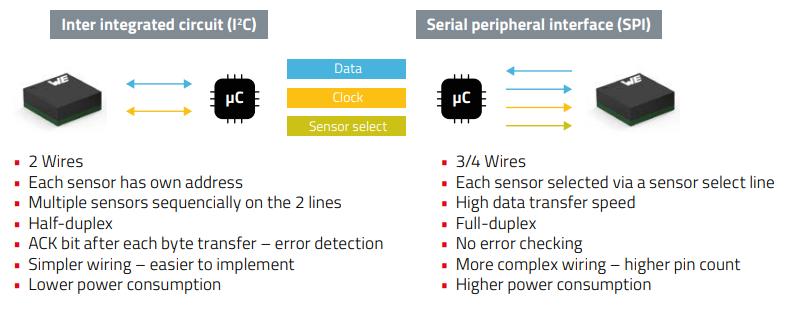

- Digital interface (I²C, SPI)

To avoid additional wiring in end device it is more and more common to replace the cables with wireless connectivity solutions like radio modules from Würth Elektronik. This requires especially sensors to be very energy-efficient, i.e. offering a very Low power consumption. With that achievement a wireless sensor network can be operated on battery by ten years and more.

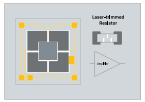

Micro-Electro-Mechanical System - Unit (MEMS)

- Bulk- or surface micromachining to create mechanical structures

- Very small dimensions possible

- Able to detect very small changes in physical dimension

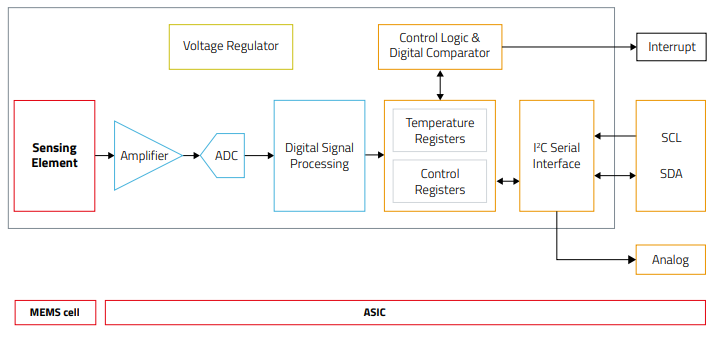

Application-Specific-Integrated Circuit - Unit (ASIC)

Analog front end:

- Amplifying the signal

- Multiplexing in case of different sensor elements

- Conversion from analog to digital value

Digital logic:

- Filtering Calibration, Compensation and linearization

- Registers and buffering

Interfaces:

- SPI/I²C – digital interface

- Interrupt /alert for special scenarios

Scale of integration

|

MEMS Cell |

Amplified Sensor |

Integrated Sensor |

|

|

|

|

|

|

|

Block Diagram

The best way to explain the function of MEMS sensors is is through a block diagram. The biggest difference to conventional (analog) sensors is that not only the actual measuring cell but also the complete processing can be integrated to achieve a very small sensor system. This eliminates any analog data processing on application level and a digital signal can be used directly by a microcontroller. Since a complete system is combined in one component, a complete factory calibration is also possible.

Sensor interfacing

How do I connect my sensor? -> Work with standard communication protocols!

Comparison Analog vs Digital sensor

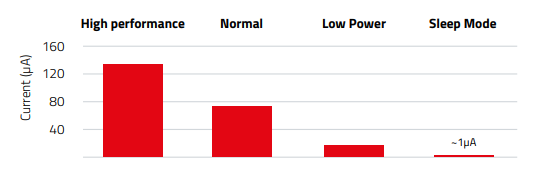

Different Modes for different Needs

Typically the mode selection is a tradeoff between current consumption and accuracy/noise.

- High performance mode with highest data rate

- Normal mode as a perfect compromise

- Low power mode with lowest power consumption

Sensors kinds Würth Elektronik offers:

If you want to read more find here the whole Product Guide.