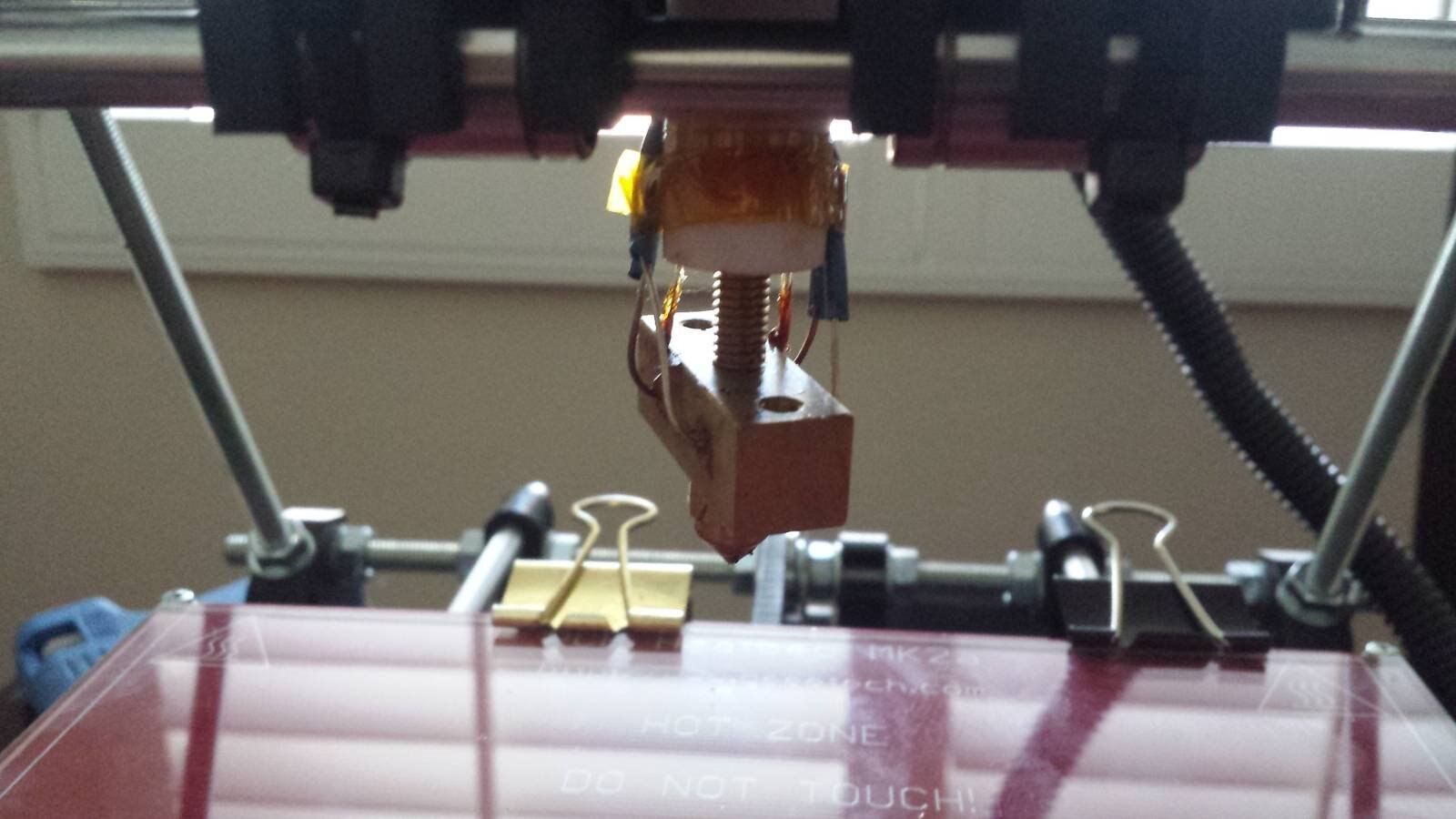

So I bought all the components I need to make a PMI2 and put it all together, being sure to measure multiple times so it can be accurate as possible. The only issues Ive had are the electronics, mainly the stepper motors. They're have some slight binding issues which are really apparent on the Z axis. I check all the angles that have to do with it and they are really accurate. I also have the rods lubricated and adjusted the power output to max for the stepper motors. The thing is I don't think that the Z motors are receiving enough power, considering that they are connected together. I've had it sitting for a few months now and I have yet to print anything.

If anyone has a PMI2 or know how I can fix the issue that would be a lot of help. Thanks for taking your time to read this.