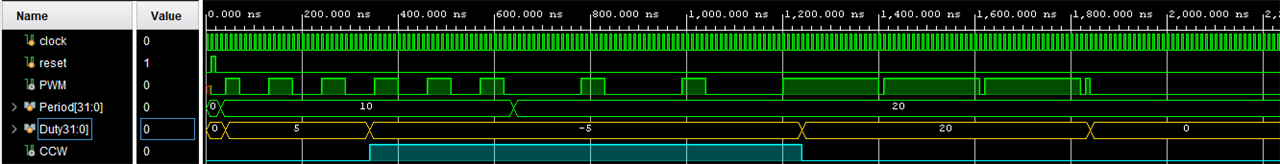

The enhanced Pulse Width Modulation (ePWM) IP creation has only one objective, to reduce the processor time required for direction control in the motor driver. It is based on a 32-bit signed int data type and can handle positive and negative values. A positive number indicates a clockwise rotation action while a negative number allows a counterclockwise rotation.

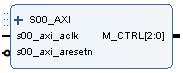

ePWM IP

The motor control port (M_CTRL) has 3 signals: Enable, PWM, and Direction. At this moment, the Enable signal is always assigned to 1, to maintain the motor activated according to the motor driver architecture. PWM handles a duty cycle from 0 to (Width - 1), this allows a complete deactivation of the channel. Finally, Direction changes the rotation direction.

ePWM simulation

`timescale 1ns / 1ps

module PWM(

input clock,

input reset,

input [31:0] Width,

input signed [31:0] Duty,

output reg oPWM,

output oDIR

);

reg [31:0] count;

wire [31:0] aDuty;

assign aDuty = Duty[31]? -Duty[31:0]: Duty[31:0];

always @ (posedge clock)

begin

if(reset) begin

count = 0;

end else begin

if(!(count < Width)) begin

count = 0;

end else begin

count = count + 1;

end

end

end

always @ count

begin

if(count < aDuty) begin

oPWM = 1;

end else begin

oPWM = 0;

end

end

assign oDIR = Duty[31];

endmodule

All the processing required by software for the direction change using a GPIO is delegated to the ePWM with a direct connection to the control terminals. The module only requires two values: the Period and the Duty cycle. This approach allows replacing the following code,

... static uint32_t pPWM; response = PID_CalcResponse(&MotorCtrl, (float)sMt -> Position); if(response >= 0) OUTS -> DATA2 |= 0x02; else OUTS -> DATA2 &= 0x0D; pPWM = (uint32_t)(fabs(response)); *Duty = (uint32_t)pPWM; ...

For the next one,

... response = PID_CalcResponse(&MotorCtrl, (float)sMt -> Position); *Duty = (int32_t)response; ...

It is required only a typecasting to accomplish the module design and all additional validations are made by hardware, obtaining the same results with less processor time.