Xilinx produced Spartan-6 technology in 2009 to use it for industrial networks, vehicle networking, and connectivity, and high-resolution video and graphics. It was a successful technology and is still used today. Since 2017 Xilinx has introduced Spartan-7 technology. Let's try to see the new features together. In the figures below Spartan-6 FPGA SP605 Evaluation Kit VS Spartan-7 SP701 FPGA Evaluation Kit.

The first thing to consider is, of course, the technology used. We have gone from a 45 nm technology to a 28 nm one. This led to a 30% increase in performance.

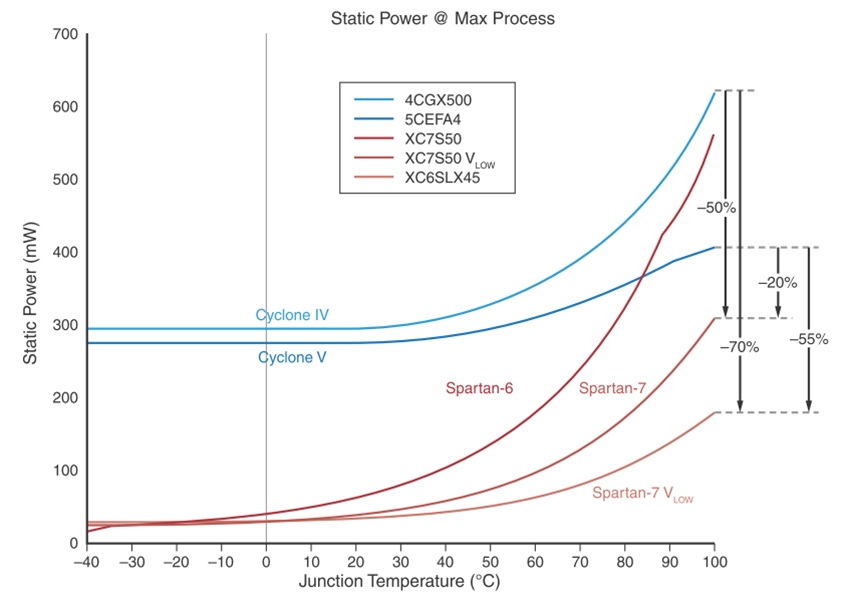

Another big advantage over version 6 is energy saving. The Spartan-7 has a 50% lower power consumption compared to the previous technology. This, in addition to allowing smaller dimensions and reducing thermal dissipation problems, reduces construction costs of the boards and those for the power supply and decreases the thermal stress of the electronic components. This optimization of consumption was also achieved thanks to the use of the Vivado Design Suite which allows obtaining an estimate of the power produced already in the design phase.

Another important difference between the two versions of the Spartan is the supply voltage. The Spartan-6 is powered with voltages between 1.0V and 1.2V, while the Spartan-7 is powered from 0.95V (Low Power Mode) to 1.0V (High-Performance Mode).

If we analyze figure 2 from "Total Power Advantage Using Spartan-7 FPGAs" we can immediately see the clear advantage of using the Spartan-7 in its two operating modes (High-Performance Mode and Low Power Mode).

Memory management is also significantly improved in the Spartan-7 compared to the previous version. While the Spartan-6 managed 12.8 Gb/s peak bandwidth DDR3 memory, the Spartan-7 managed 25.6Gb/s peak bandwidth and has an efficient soft memory controller for greater flexibility.

Another improvement feature of the Spartan-7 compared to the previous version is the presence of dedicated IP blocks like the XADC integrated dual 12-bit analog-to-digital converters, to help reduce overall BOM cost.

The presence of an ADC increases the flexibility in the use of the board and the possibility of managing analog inputs without the need for additional hardware. This increases the potential of the board and reduces the development cost by using only onboard components.

Also considering the possible uses of the Spartan-7, another feature not present in the previous version is the management of security at a very high level, using the symmetric algorithms AES256 and SHA-256. This makes the Spartan-7 suitable for implementing industrial devices that have to manage safety.

Finally, I want to mention another feature implemented in the new version of the Spartan, namely the integrated supply voltage and thermal monitoring. This makes it easy to check the critical values of voltage and temperature to have continuous monitoring in real-time and without using additional sensors or boards.

A substantial difference between the two versions of the Spartan lies in the software used. The Spartan-6 uses "ISE Design Suite" while version 7 uses "Vivado HLx Design Suite WebPack", a much more complete and versatile software but also more greedy for hardware resources.

We conclude this short article by summarizing what we have said, the Spartan-7 is the evolution of version 6 and has brought many improvements obviously due to technology but also to a better organization of resources.

Finally, here are some practical examples of projects made with Spartan-7 (Arty 7).

Have fun!