I know a lot of you are busy with the Sparty 7 board so there may be a lack of bandwidth.

Many parts are unobtainable now: Farnell list 541 Xilinx FPGAs of whcih two are in stock:

These are nice enough parts but no good for playing with at home ! (and anyway they only have one of each)

Lattice and Altera used to be good for simple parts in reasonable packages but have also becom impossible to buy.

I've been keeping an eye on the market and especially on Gowin and Efnix.

For simple prototyping and projects you need packages you can solder by hand or with simple gear (TQFP or QFN).

And for small budget (home or commercial) projects you need simple dev software, small gate counts and low cost.

Digikey currently have Efnix T8 and T20 parts in 144 pin TQFP in stock at £5.73 and about £10 each in small numbers. They have thousands.

The T8 gives you 8k LUTs, 8 18x18 multipliers and not a lot else, but it is low power and quite big enough for all sorts of good work (about half of my commercial designs have used less than 8k LUTs)

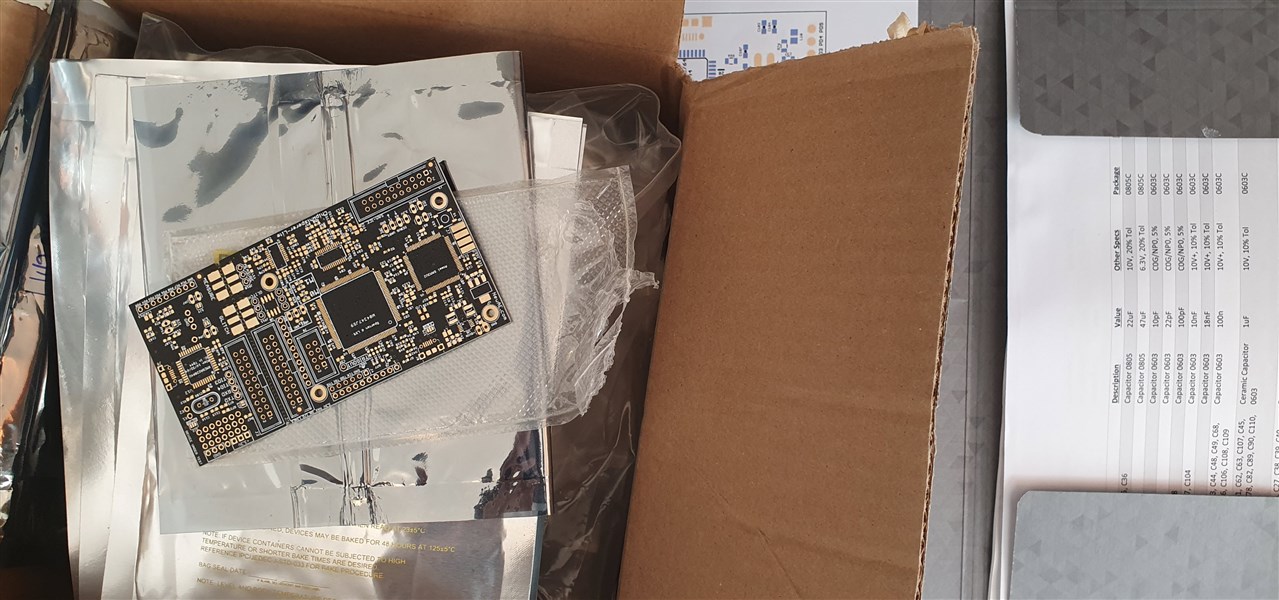

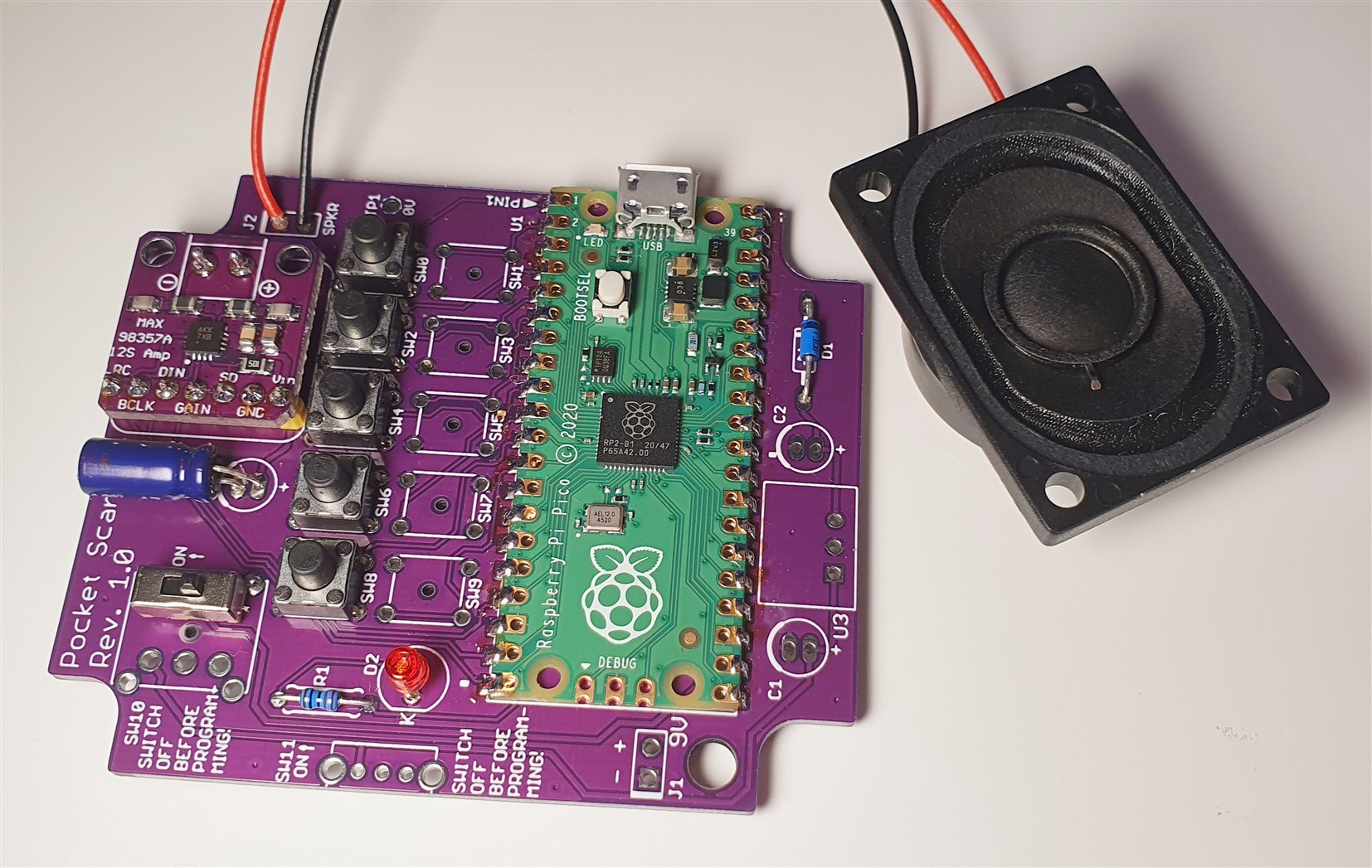

I've ordered a dev board £74 and a few chips.

Mouser have some Gowin parts but the prices are a bit high.

MK