Previous posts for this project:

- [AirCare] InTheAir - Project Description

- [AirCare] InTheAir - Week 1: Getting a Launchpad to Blink

- [AirCare] InTheAir - Week 2: Preparing the Beaglebone Black

- [AirCare] InTheAir - Week 3: Fuel Tank Testing

- [AirCare] InTheAir - Week 4: Using the CC3200

- [AirCare] InTheAir - Week 5: openHAB and MQTT

- [AirCare] InTheAir - Week 6: Accessing Fuel Tank's Data

- [AirCare] InTheAir - Week 7: Dust sensor

- [AirCare] InTheAir - Week 8: MSP430FR5969 with Energia14

- [AirCare] InTheAir - Week 11: CC3200, Energia and analogRead()

- [AirCare] InTheAir - Week 12: Automatically starting some things

- [AirCare] InTheAir - Week 13: GP2Y10 BoosterPack

Introduction

This post is more of a small update, as I didn't find enough time to dive deep into this project this week.

Parts

I have ordered various parts for the project over the weeks. I'm still missing some key components to populate the PCB from last week, I hope they show up before the PCB does.

The capacitor kits from Würth, which I ordered before Christmas have arrived this week. They look great! Big thanks to sleuz for arranging that.

PCB

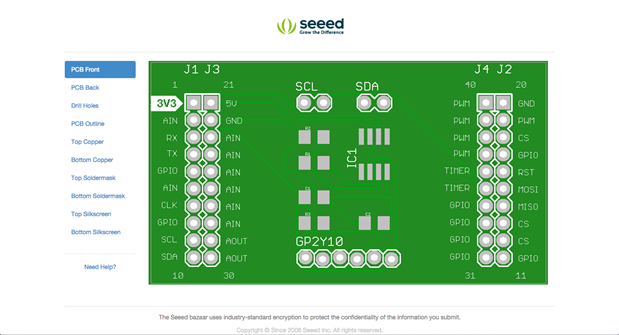

We were given a 50EUR budget to get our PCBs made via Würth. Quoting my little board for the sensor, the total cost would've been around 75-80EUR for one board. Taking into account the 50EUR reduction, that would still have been 25-30EUR.

I don't have a problem paying things for the challenge myself, as we already get so much. But I do think that the quality Würth would've delivered for that price would have been overkill. The PCB will mainly be used to practice surface mount soldering and create a first prototype.

So instead, I opted for SeeedStudio. For 12EUR, I'll be getting 10 pieces of my PCB design. This will give me the chance to practice and possibly mess up a few boards without much consequence. If the design proves to be correct and functional, and after becoming a bit more skilled at surface mount soldering, I still might order a "final" board via Würth.

Top Comments

-

amgalbu

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

fvan

in reply to amgalbu

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

fvan

in reply to amgalbu

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children