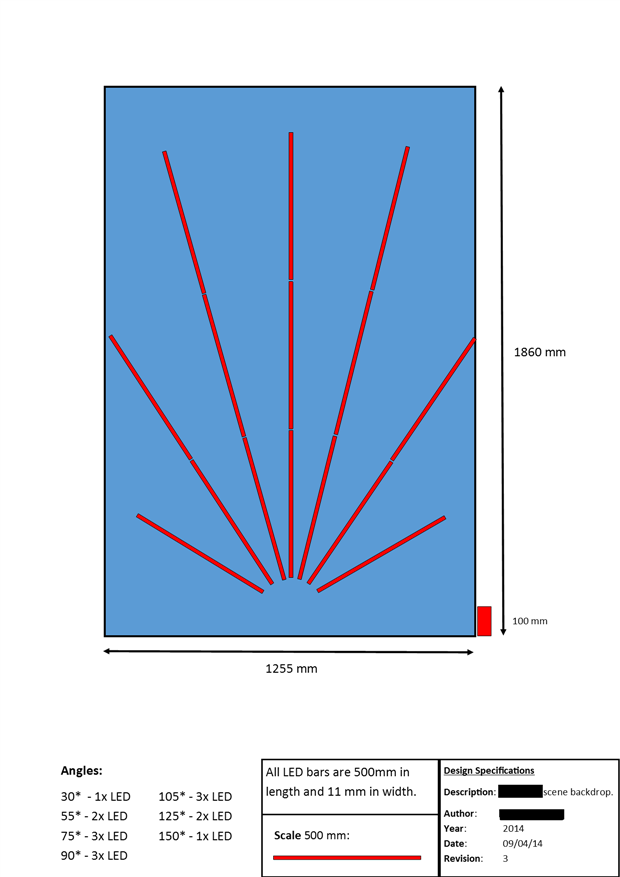

One of the directors has asked me to create a special backdrop for our college musical. This particular backdrop has a particular design (see below) that includes LED strip lighting to give the feel of a 1920s casino sign – similar to what is seen today in Las Vegas.

I have done up a detailed design for this sign, based off the rough sketch given to me by the director and the dimensions of the backdrop. On this diagram, the arrangement of the LED strip lighting can be seen.

The LED Strip lighting that will be bought for this project will be sourced from Jaycar – “Low Cost 5m Flexible Adhesive LED Strip Light – Warm White” (ZD0577). According to the specifications off Jaycar’s website, these LED lights need 1.1 Amps per metre @ 12 volts. This means that the longest segments of lights need 1.1 * 1.5 = 1.65 Amps of power (rounded up by 20% for safety: 2.0 Amps @ 12 volts).

This would not be an issue if I was just turning these LED Strips on and off with mains power BUT I want to control these LEDs via an Arduino, so that they can do fancy things like flash and chase. That means that I would need a circuit to control these lights with an Arduino so that everything remains safe and does not blow up.

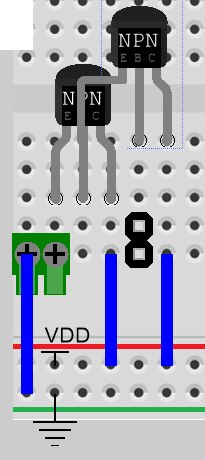

I have come up with this circuit (below) using a couple of NPN transistors and two power supplies. In the diagram below, I am aware that the transistor pinouts are EBC. The ones I am going to buy have a pinout of BCE.

The only problem with this is that I have very little understanding of transistor circuits. What this circuit has to be able to do is:

- Using the smallest amount of current from the Arduino (at 5 volts) or a Raspberry Pi (3v3 volts), turn on the circuit to allow the 12 volts that powers the LED strip lighting to flow.

I was thinking of using either TIP41C NPN Transistors (in a darlington Array) or TIP122 NPN transistors.

This circuit will be replicated 8 times over to accommodate for the number of LEDs I am controlling.

Can anyone help me:

- Design a circuit that will work 100% and will be safe (ie: low heat)

- This includes base resistance

- Confirm which transistors I should be using for this project.

Any help will be much appreciated.