|

Part 2 of the exercise to create a custom footprint for the Amphenol / SV Microwave SF2921-61506-1S SMA coaxial connector. The previous post checked the possible layout. In this one, I'm drawing it in the footprint editor. This is the proposed design:

|

Create a new library and footprint

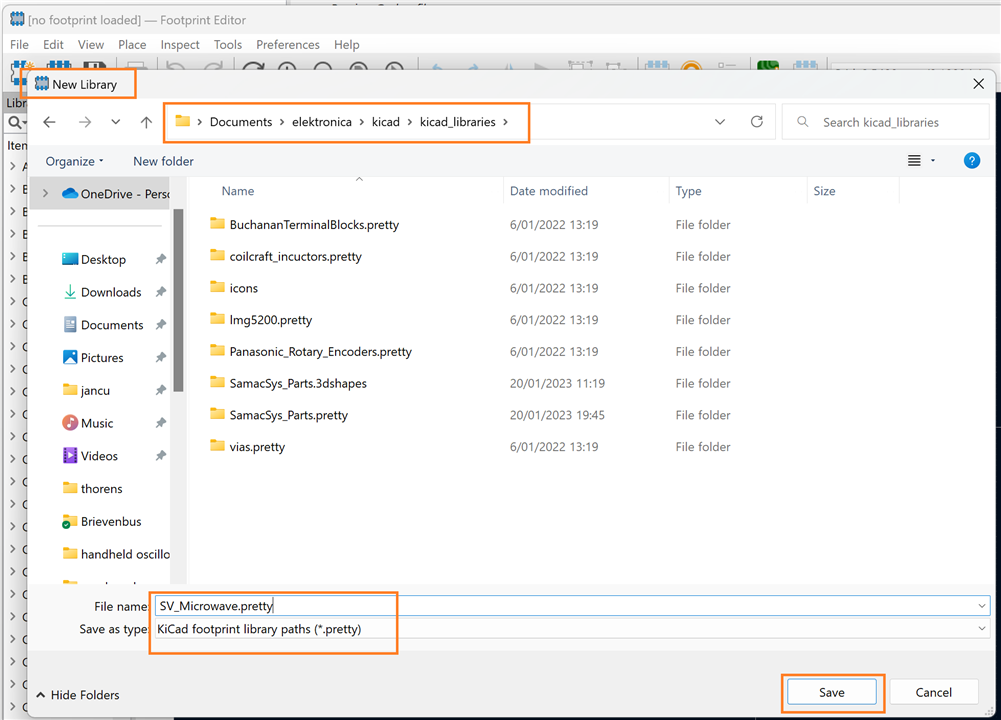

I have a directory with custom footprints that I made or collected. I'm creating anew one for SV Microwave.

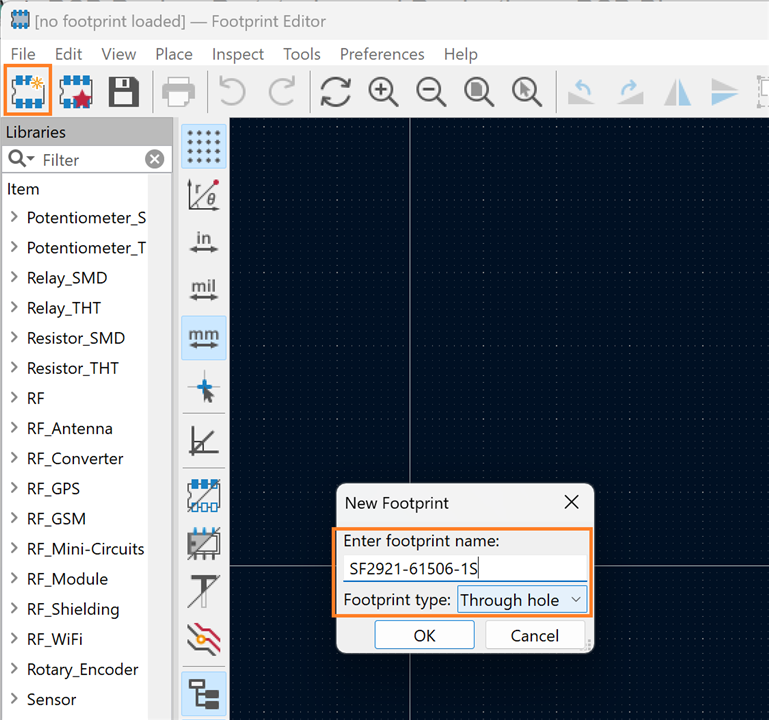

Then I add a new footprint for the SF2921-61506-1S:

That's the starting point. I did a first save at that point.

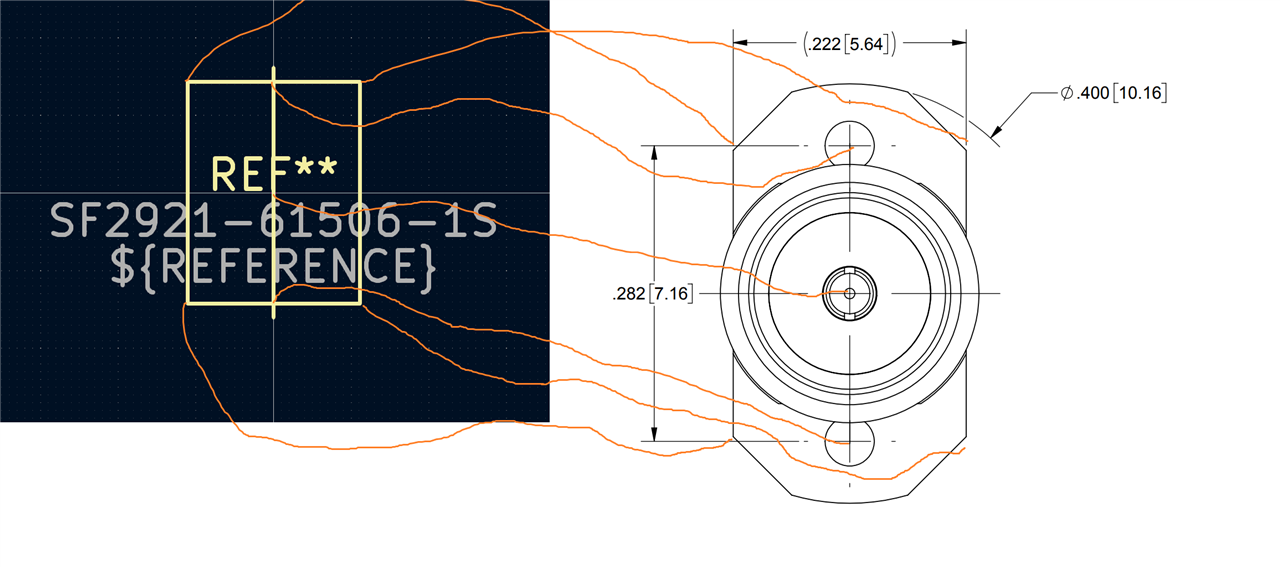

Step 1: initial outline

I try to start with a simple drawing that has a few reference points for later. Usually, I search for some square or rectangular simplification. In this case, I took the rectangle defined by the width of the connector and the distance of the drill holes for the screws. That immediately gives me 5 data points:

- width

- middle point where the spring sits

- the two drill holes

- middle point for the circle that defines the most outer vertical limits of the base

- the mouse hole where the microstrip will escape

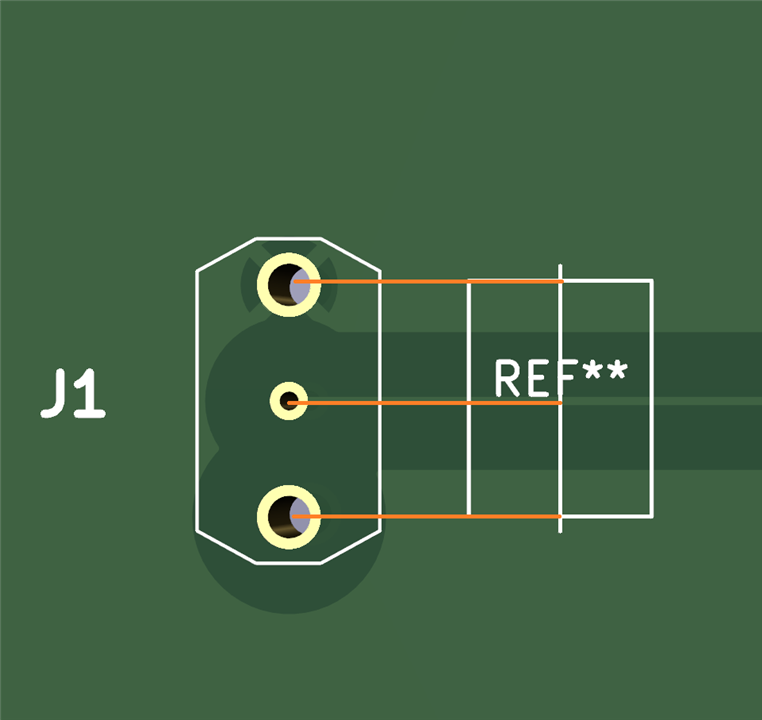

Quick check, compared to the stock footprint:

due to time limits, this post will be broken up in chunks. I try to keep these chunks big enough to document a step in the exercise.

Blog Index

- Overview: Amphenol / SV Microwave SF2921-61506-1S SMA coaxial connector series

- Amphenol / SV Microwave SF2921-61506-1S SMA coaxial connector: behavior under vibration

- Create a custom footprint in KiCad 7 - 1: collect info and component details

- Create a custom footprint in KiCad 7 - 2a: create the footprint for an SMA coax connector with the editor - initial outline

- Create a custom footprint in KiCad 7 - 2b: create the footprint for an SMA coax connector with the editor - copper pour, solder mask clearance, holes, pads

- Use a LibraryLoader Footprint in KiCad 7

Top Comments