I usually provide the technical details and documentation on a roadtest page for people to look over at their leisure.

I usually provide the technical details and documentation on a roadtest page for people to look over at their leisure.

This material usually gives people ideas on how they would like to roadtest a product. But I think sometimes, it's good to actually talk about how one would roadtest a product, due to perhaps it's something new for many people, or it needs a little more background.

I think this angle sensor kit is one of those products.

When we decided to roadtest this kit, we initially provide the sensor and the communications board. But with only those things, the roadtester would have to mount the magnet and the sensor to the motor shaft. Seemed like heavy lifting, so the supplier came back with the kit that's on this page (right):

community.element14.com/.../mps_magnetic_angle_p

The sensor board is mounted to the end of the motor shaft already (as well as the magnet). The roadtester would need to hook it all up, connecto the Arduino board (not shown in the image at the right) and spin the motor.

But still, how do you actually test it.

More importantly, why is this sensor important to roadtest?

This clip from the sponsor's website pretty much explains it:

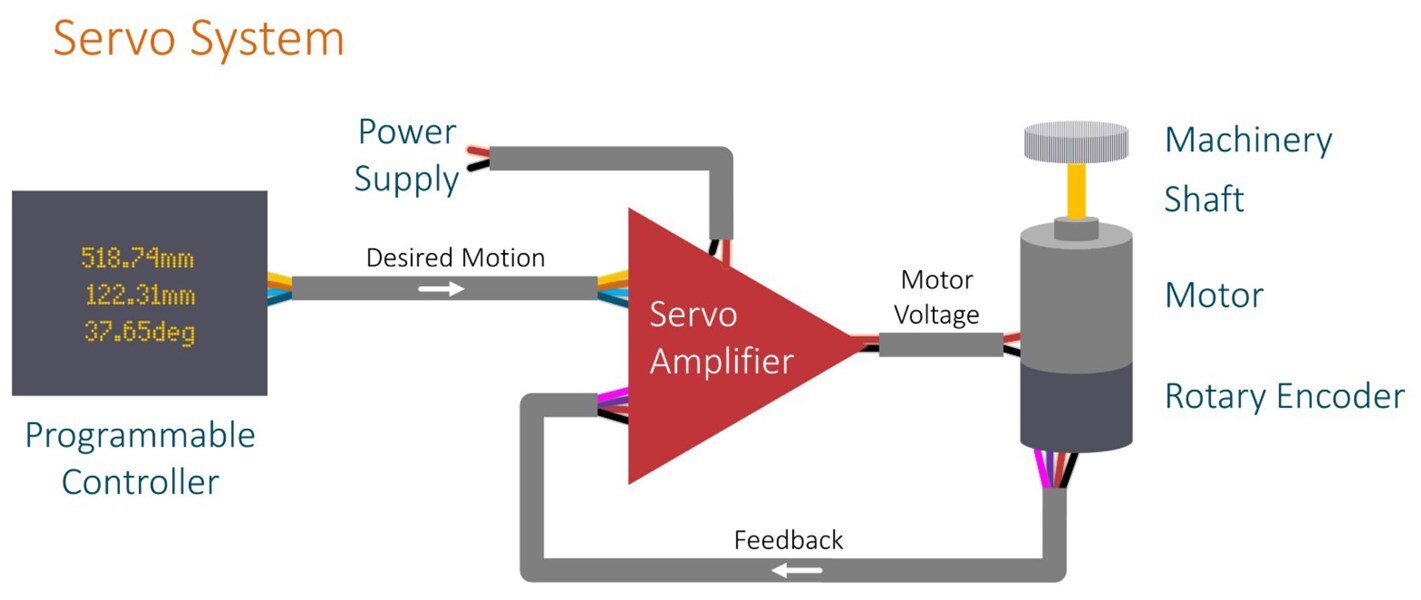

The ability to detect position or speed is a fundamental requirement in the control and monitoring of many mechanical systems. Slow speed position measurement in applications such as motorized actuators has historically used resistive potentiometers. In high-speed applications such as servo motors, optical encoders have typically been used. Though potentiometers are inexpensive, they suffer from the drawback of being a moving contact-based assembly, which brings the associated issues of mechanical contact wear and susceptibility to damage from external environmental factors including moisture and dirt ingress. Optical encoders offer high accuracy, but come at a higher price due to the complex nature of their construction. Engineers can solve this dilemma by using contactless rotary magnetic angle sensors that implement Hall-effect sensing.

This page goes into detail about the angle sensor, specifically about its SpinAxis technique: www.monolithicpower.com/.../introduction-to-the-magalpha-magnetic-angle-sensor-family

The kit we are providing to the roadtester is a motor control kit. But we would like to get roadtesters to take a closer look at the angle sensor. Run some tests, play with it, and give some feedback or thoughts about it.

So, that's my backgrounder.

What do you think?

How would you test the sensor?

Even if you don't have the time to take on this roadtest, I'd appreciate your input. It would benefit those members who are thinking about applying.

Thanks.

Randall Scasny

RoadTest Program Manager