Intro

During this year's Experimenting with Extreme Environments design challenge I have decided to continue my work of identifying edge cases of environmental origin when deploying electronic systems outdoors. And - as of outdoors - I am not even thinking about some desert area with extreme daily temperature changes or seaside with salty mist and occasional submersion during storms. My "outdoors" is (save one testcase, when I have decided to check the impact of very low temperatures on the LCD display operation) a roofed balcony in the Central European city during spring months (with some historic data from the late autumn as a reference).

In this place I would like to thank our sponsor - Hammond Manufacturing and the organizer - Element14 for allowing me to continue my (hobbyist level) research.

This year we were provided with the following design kit:

- Hammond Manufacturing 1554VA2GYCL IP68 rated plastic enclosure,

- Raspberry Pi Compute Module 4 Lite with the antenna ,

- Raspberry Pi Compute Module 4 IO board ,

- Midas 20x4 LCD display ,

- 4 pin socket with matching plug from Amphenol CS,

I have done more detailed unboxing in my five extra blogs, so let's quickly summarize:

Hammond 1554VA2GYCL is an UV hardened, outdoors operation rated, IP68 enclosure, shipped with the transparent lid (one of possible configuration options), connector cut-out for the MRD socket and manufacturer's and Element14 logos printed on the top.

Raspberry PI Compute Module 4 is an Raspberry Pi version dedicated for embedding into equipment, and with addition of IO board forms an standalone SBC with the parameters comparable to Raspberry Pi 4B.

Midas LCD display is a character capable of displaying 4 lines of text, 20 characters each with extended temperature range. Based on RW1063 chipset - similar to the standard Hitachi HD44780, but with additional serial interface options - is configured for I2C connectivity and 5V power supply.

Data acquisition system

To have a possibility to properly evaluate our 1554VA2GYCL IP68 rated enclosure I have created data acquisition system, obtaining data from four (or even five) different enclosures:

- one IP65 rated, but without gasket between lid and the body, colored red with transparent lid - simulating improperly sealed enclosure,

- one IP65 rated, complete, no openings and colored light grey (lid and body) - that one was planned as good insulation example, anticipated to behave better than test enclosures (but the life have said differently),

- one IP65 rated, complete, no openings and colored black (to verify the influence of color in the process of solar radiation inducted heating),

- one IP68 rated 1554VA2GYCL with one opening and colored light grey with transparent lid - this is the main object of our tests,

- one IP68 rated 1554VA2GYCL, obtained from last-year Design Challenge, fitted with several waterproof connectors, and one modification - Pressure Compensation Valve installed, to discern the effect of pressure inducted gasket failure (which I have experienced last year) to the level of humidity inside,

Each enclosure was housing a battery-powered (to not have to create additional openings in the enclosure) sensor, which was gathering data about temperature, relative humidity and air pressure inside and transferring them (using WiFi) to the central station. Each sensor was designed with power-conservation in mind, waking up every 10 minutes, doing the work and then going to power saving mode again.

Central station - as there is no such strict data-conservation policy needed, was created using a high-performance SBC, like Raspberry Pi 4 (provided in the Compute Module version).

To obtain additional reference data, three other data sources were used:

- report data from METAR Meteorogical Aerodome Report) format, provided by National Oceanic and Atmospheric Administration of US for more than 4000 airports around the world,

- data from two different external weather sensors (the same as usually included with wireless weather stations), that were intercepted using RLT-SDR dongle and an rtl433 decoder software,

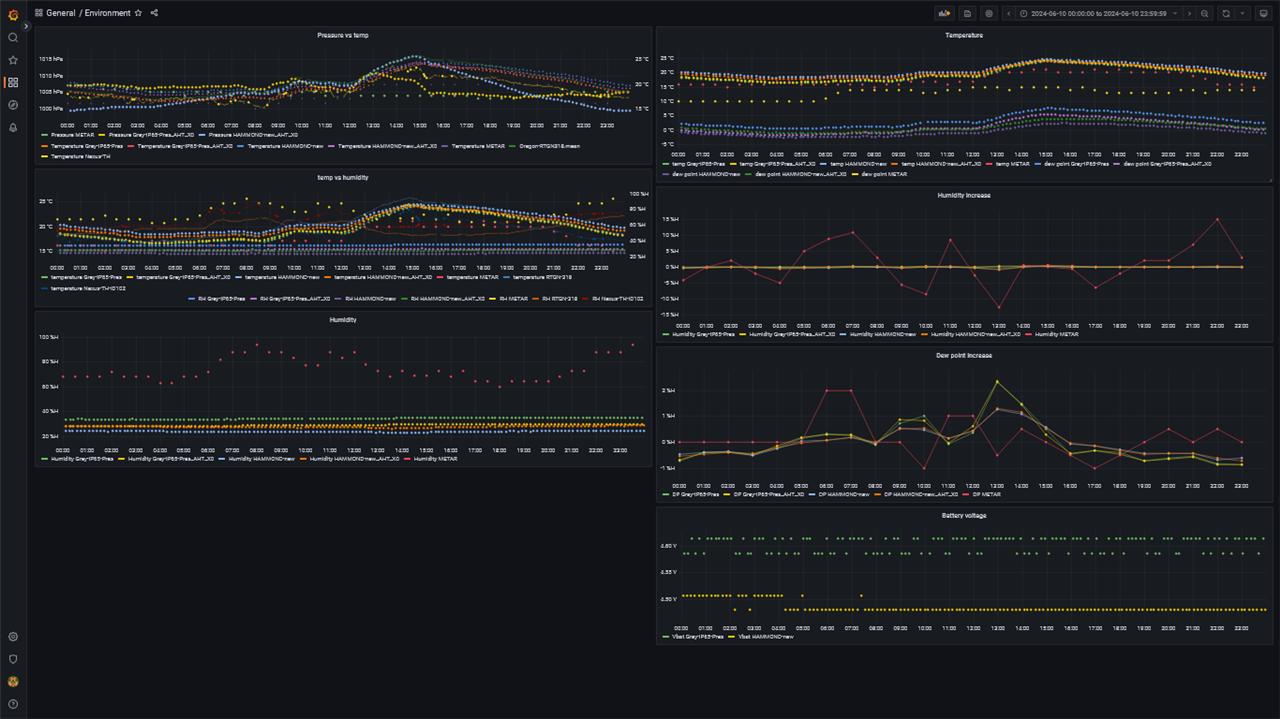

All the data were stored in InfluxDB Time Series Database and visualized in Grafana, using dashboard as on the screenshot below. Many different graph types were created to analyze potential correlation of parameters measured (for example - temperature and relative humidity).

Sensor design

After initial diversity of sensor designs (there were ESP8266 and ESP32 boards of different make used, along with different sensor types), one uniform sensor design was selected, consisting of:

- Wemos D1 mini v.3 clone board,

- DHT22 temperature and humidity sensor,

- AHT20 temperature and humidity sensor,

- BMP280 temperature and pressure sensor,

- J5019 battery charger and step-up converter,

- BMS module,

- and some passive elements (mainly voltage divider to measure battery voltage),

with the schematics as below

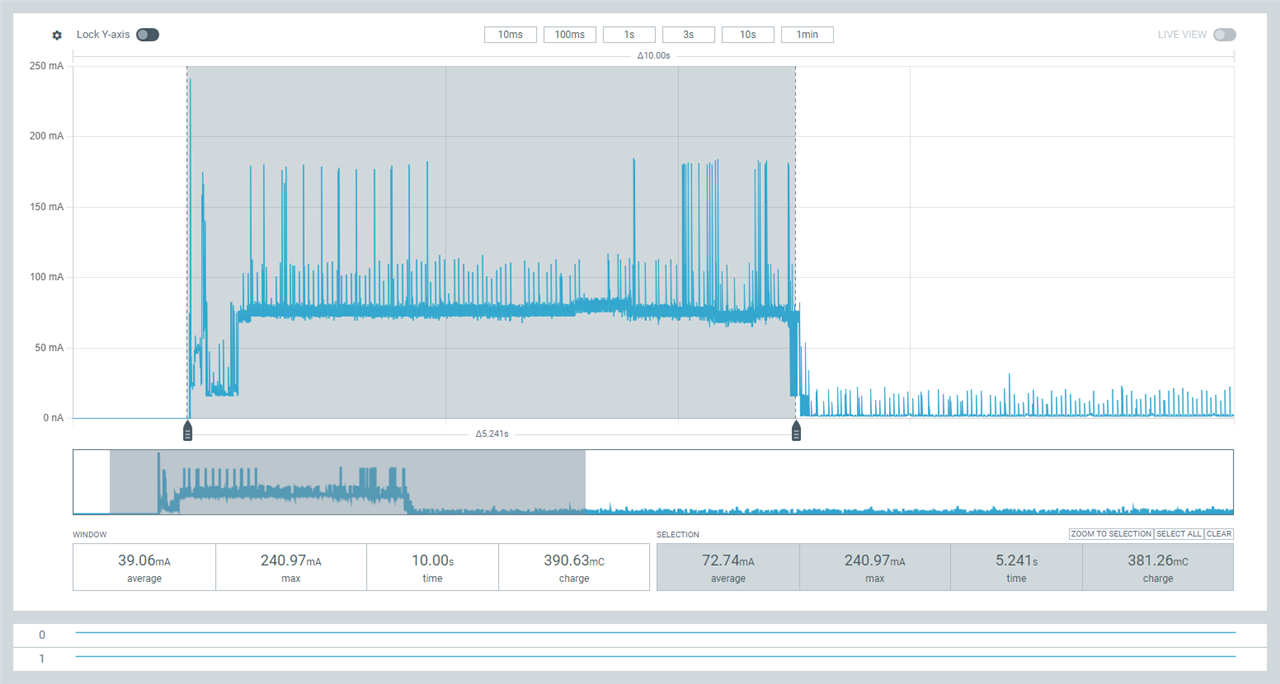

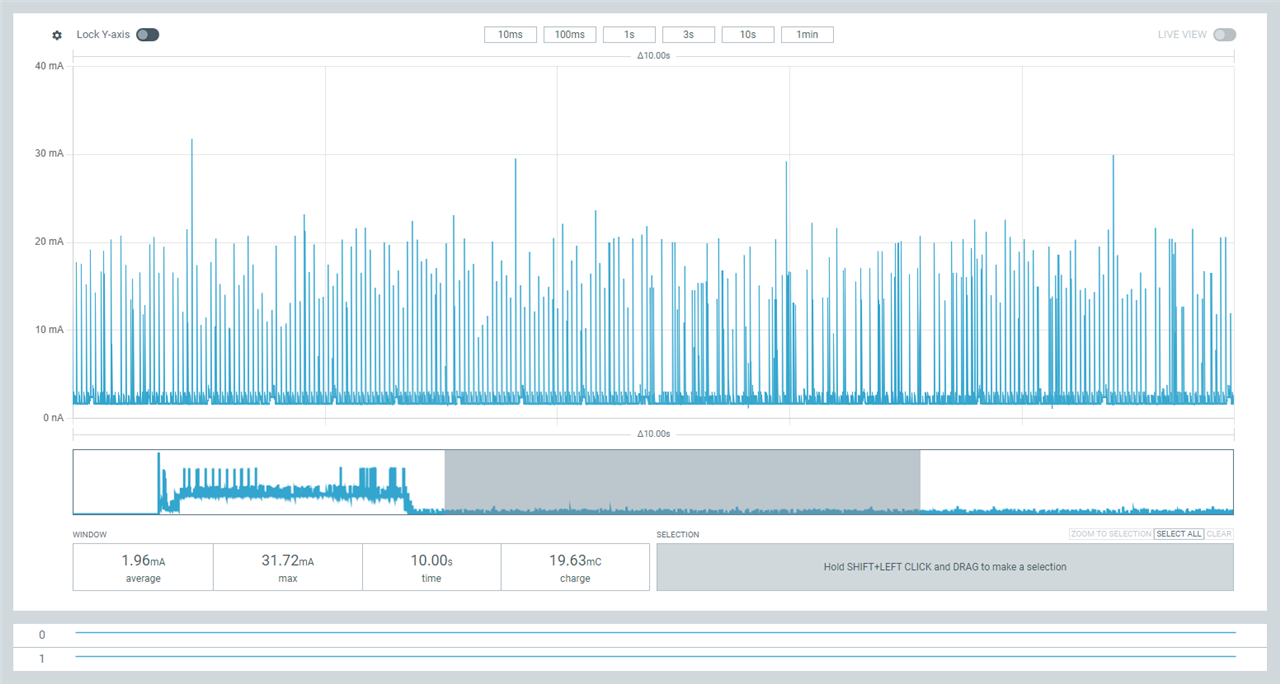

After some hardware selection (and probably development environment upgrade - one of designs, considered power-hungry last year, using current development tools behaved much better than before), following power consumption envelope was obtained

As can be seen - during most of the time (it wakes for several seconds every 10 minutes), sensor consumes about 2mA, and during the active average phase power consumption is about 40mA, peaking at 240mA.

Sensor was build using a half of 15x9cm universal PCB, and installed in the vertical rails of the enclosure.

Each enclosure was fitted with color-changing humidity absorbing gel bag - amber colored when dry, to absorb an initial humidity possibly stored in the construction of the sensor or introduced with the air when enclosure was opened.

Experiments

Several tests were conducted on the project, some of them testing parameters of individual components.

Raspberry PI CM4 free air operation

To verify that Raspberry PI CM4 can be operated without any additional heatsinks or fans, 30 minute load test was conducted on the system before it was installed in the enclosure. Results were as below, proving that throttling mechanism works as advertised, keeping SoC temperature within limits:

More details in my first blog.

Raspberry PI CM4 closed space operation

To verify if installation within non-ventilated case doesn't compromise heat dissipation ability of the system, the same test was conducted with Raspberry PI CM4 inside of 1554VA2GYCL enclosure. There were no major problems observed - temperature within enclosure was higher by about 1.8°C, and no temperature buildup was observed. More detailed description can be found in my second blog

Hammond enclosure with MRD connector water immersion

To verify information from the documentation that MRD connector used is rated IP67 only when in mated condition, water immersion tests were conducted. Test results were as expected - 1554VA2GYCL with MRD socket installed was waterproof when integrated dust protection cap was installed, but started to leak when the cap was removed, resulting in observable water penetration:

Full experiment description can be found in my second blog.

Midas LCD high and low temperature operation

To verify LCD display operation in high and low temperatures, additional setup was prepared. Dual LCD temperature meter was heated to about +40°C then chilled (in the freezer) to about -12°C. No excessive contrast level variations were observed, but at low temperatures LCD display refresh ratio decreased - to the level that using some interactive (like menu-based) user interface could be annoying. More information in my fifth blog

Color influence on solar radiation heating of the enclosure

UV radiation can be damaging to unprotected plastics - prolonged exposure can lead to discoloration and cracking - which will ruin not only aesthetic aspect of the installation but waterproof properties too.

One of the most often employed methods of improving UV resilience is an addition of soot - which, as as side effect, changes plastic color to black (so common wisdom says that black cables are for outdoor installations and grey are for indoors). But - as dark colors absorb more solar radiation than the light ones, another test was performed. Four enclosures:

- light gray

- black

- dark red with the transparent lid

- light grey with the transparent lid

were placed under the direct Sun radiation and the temperature inside was measured.

Maximum temperatures were as follows:

- light gray: 51.4°C

- black: 67.6°C

- dark red with the transparent lid: 78.3°C

- light grey with the transparent lid: 78.3°C

The conclusion of the results can be that for temperature-sensitive components, enclosure should be light gray (or even white if possible) and without transparent window - fortunately, Hammond manufactures enclosures of light gray color which are UV hardened.

More details in my fourth blog,

Pressure caused humidity leakage in hermetic enclosures

What can be done to create ultimate water resistant enclosure? One would say "use the best sealing possible" - but maybe not in every situation?

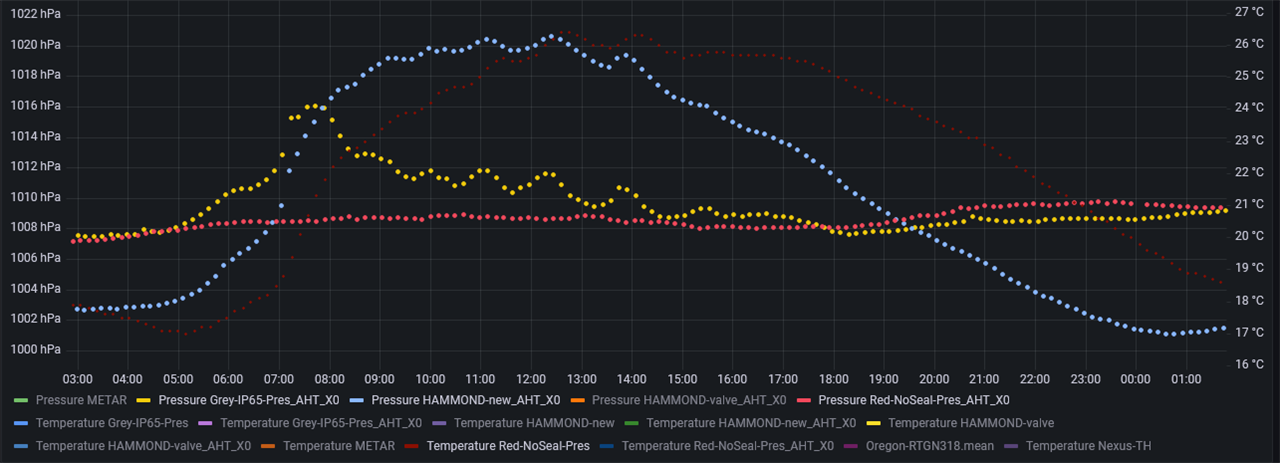

As we know, gas pressure in the closed chamber changes with the temperature - it rises when temperature rises and lowers when temperature lowers - something like on the graph below (green is the temperature, blue is the pressure inside the box and red in the reference pressure outside). We can see some imperfections - the whole descending part starts too early and goes too low, but in average it is almost as theory states.

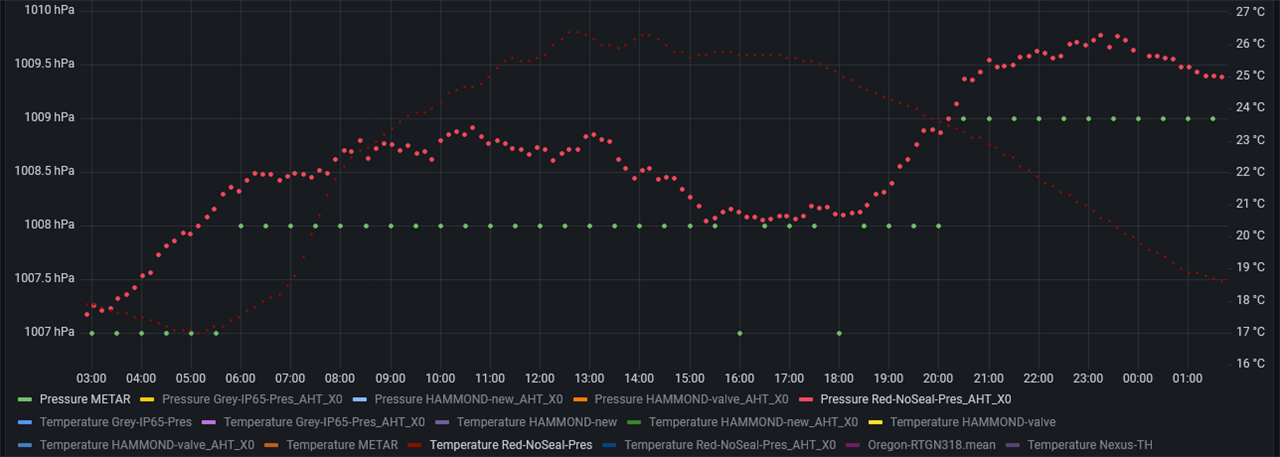

Now, what about the box that is not well sealed - there the pressure would closely follow external pressure, without much influence from the temperature (small red dots are temperature, big red dots are pressure inside the box and green dots are official pressure data from METAR reports) - we can see that the pressure inside follows the pressure outside instead of the temperature

So - what can happen when the seal is too good and allows for excessive pressure buildup? Gasket failure and mayor air exchange with the external environment can happen (that can cause humidity buildup inside when external humidity is high and air exchange events - prolonged). Small red dots are temperature, large ones - reference pressure, blue ones - pressure inside the Hammond enclosure and yellow ones - pressure inside by reference, grey enclosure. Here we can see that after initial gasket failure, pressure inside grey Z74 lowers up to the level of the external pressure. There seems to be also some gasket leakage in the Hammond enclosure - indicated by uneven envelope of the pressure curve, but to much less effect than in the reference enclosure.

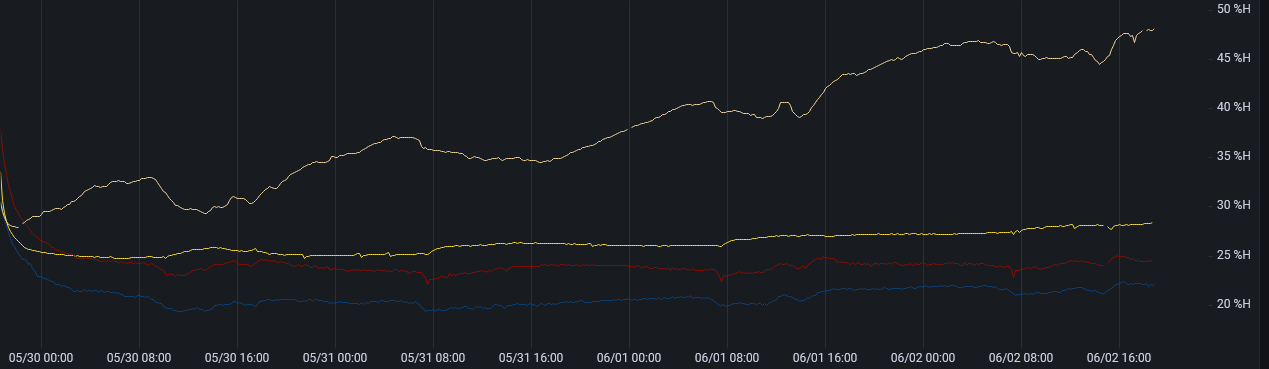

And - what is effect of all of this on the long-term humidity increase inside the box? The following graph presents data from:

- uninsulated box (beige curve)

- Hammond test enclosure (red curve)

- reference Z74 box (blue curve)

Taking into consideration that we are measuring relative humidity - which means that humidity value of the gas containing the same volume of water vapor changes with the temperature, so numeric measurements can be compared only if temperature is the same, we can see that in our - in the theory - best insulated box humidity buildup is greater than in the Hammond enclosure, despite it's bigger volume and installation of one connector (that can create some leakage points).

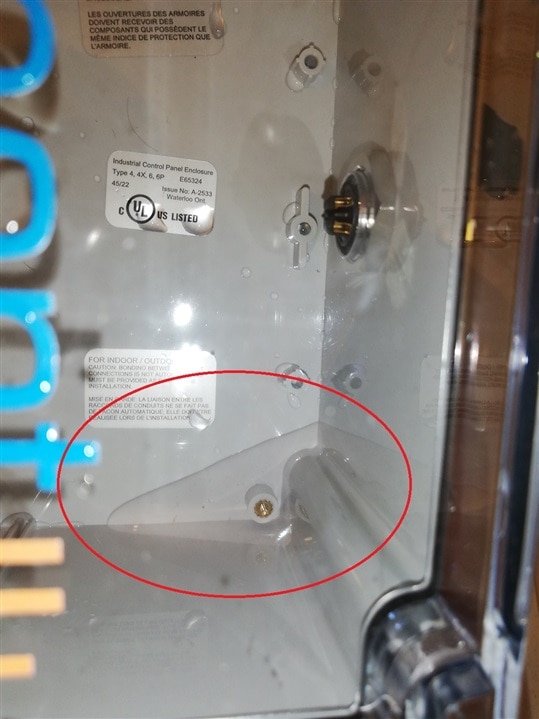

Another example of the effect of excessive pressure buildup on the enclosure operation can be seen on the following photo - when dust protection cap was opened - apparently - by the excessive pressure inside caused by the direct sunlight radiation.

And the corresponding pressure curves as follows (red is temperature, yellow is pressure) - we can see sudden pressure drop with no corresponding temperature decrease, indicating protection cap opening:

Temperature swing effect on humidity migration

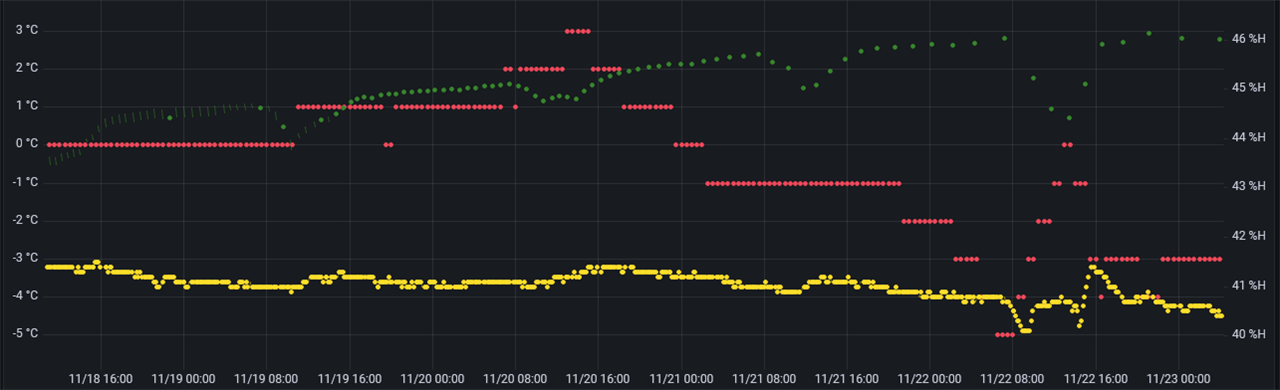

As we have seen, temperature changes can have negative effect on the operation of sealed waterproof enclosures - but is it really a case? Maybe this grey Z74 is simply not sealed properly, thus giving worse results? To check this, I have found data from the autumn of 2023, when - during the brief period of near-constant external temperature (red dots) and very high humidity, RH inside the grey Z74 (yellow dots) stayed nearly the same, while inside Hammond enclosure humidity slightly increased (green dots).

Pressure Compensation Valve - a silver bullet?

So - what can one do to have waterproof enclosure, but not a sealed one (to prevent/limit pressure caused events). It seems - install Pressure Compensation Valve (a.k.a. Pressure Compensation Cap). I have obtained one of those - icotek kindly sent me one of their IP68 rated PCP's as a sample, for which I would like to thank them.

They are constructed as a cap with some membrane inside, designed to allow for air flow, but preventing migration of water/water vapor.

I have installed it in the place of one of the connectors in the last year's Design Challenge's enclosure and included in the experiment.

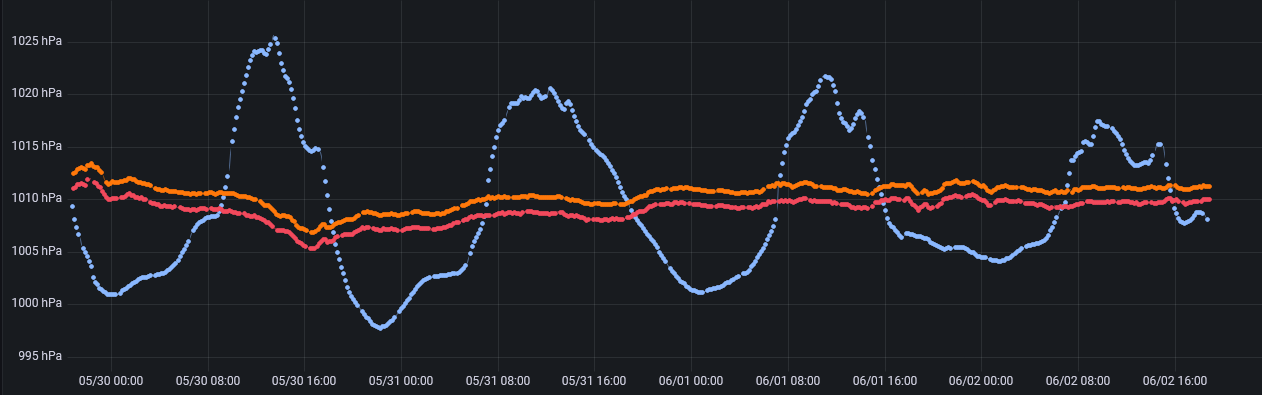

First - is it really reduces pressure inside? Blue dots are from Hammond enclosure, red from unsealed red Z74 and orange from Hammond enclosure fitted with Pressure Compensation Valve. So - it works, pressure inside is nearly the same as in unsealed enclosure.

Next - if the pressure is like unsealed enclosure, what's about humidity - does behave better than the unsealed one? Biege dots are unsealed enclosure, yellow are from sealed grey one, red are from Hammond enclosure without PCP and blue are from PCP fitted Hammond enclosure. One can see that the enclosure fitted with PCP behaves in similar way that the other Hammond enclosure.

As a last test - as the batteries used were less reliable than anticipated, resulting in premature disconnection of some sensors during the test, humidity absorbing gel was examined. As it is a color-changing version, one can assume from the color change which enclosures were subject to the most of humidity (R - is from unsealed red enclosure, G - from sealed Z74 enclosure, DUT from PCP fitted Hammond enclosure and unmarked from this year's Hammond enclosure):

and then some close-ups:

unsealed red enclosure:

grey enclosure:

Hammond enclosure without PCP

PCP fitted Hammond enclosure:

From the state of silica gel, it seems that the lowest humidity was inside the enclosure from this year's challenge (without PCP and with only one connector).

Summary:

As we have tested, all elements of the Design Challenge's challenger's kit can be operated in not-exactly-room environment, but there are some facts to consider.

First - LCD display refresh rate drops in low temperatures, which can impede operation if user interface type is not correctly chosen.

Second - connector provided is waterproof only when mated or when dust cover is installed. Caution should be exercised to not leave it open and not connected.

Third - transparent lid is a sub-optimal choice when direct solar radiation is anticipated. In this situation, much better could be UV hardened Hammond enclosure with solid light grey lid.

Fourth - humidity migration through failing gasket can be anticipated when big temperature changes are expected. Using Pressure Compensation Cap can reduce this effect, but probably at the cost of some small additional humidity migration (it seems that humidity level inside PCP fitted enclosure raised somewhat more than in a sealed one, but as those enclosures were not equal [one fitted with PCP had also many different connectors installed], additional tests are needed).

References

Exploring hidden extremes of sheltered environment - blog 1, introduction and Raspberry PI

Exploring hidden extremes of sheltered environment - extra blog 4 - greenhouse in the box

and the reference to my last year's work

Monitoring station for Underground Cold Storage (Final results blog)