Welcome to the EAO page on element14. Here you can find things such as our latest news, training videos, and product details. Additionally, you can engage with us in our forums.

EAO Ltd, Burgess Hill, Oct 2025 – EAO Ltd has launched the Sanyo Denki 9LG38 Series Long Life DC fans. Measuring 80 × 80 × 38 mm, these fans feature a black coated die-cast aluminium frame and dual ball bearings, offering up to 100,000 hours of operation at 60°C (or 135,000 hours at 40°C).

Ideal for hard-to-service applications like telecoms and solar inverters, the fans are available in two speed options and 12, 24, or 48 V, delivering a maximum static pressure of 1260 Pa and airflow up to 3.42 m³/min (120 CFM).

Features include a built-in tachometer for speed monitoring and optional PWM control to reduce power consumption and noise.

EAO Ltd provides expert cooling system advice and thermal design support, including Sanyo Denki Portable airflow testing.

More information: https://motorsandfans.co.uk/new-sanyo-denki-80lg38-long-life-fans/

Burgess Hill, UK – 04 August 2025 – EAO Ltd is pleased to announce the availability of the new San Ace 80 9CRHA Series from Sanyo Denki—a high-performance line of 80 × 80 × 80 mm counter rotating DC fans engineered for compact systems requiring exceptional static pressure and airflow control.

Built to meet the challenges of high-impedance environments such as telecoms, power modules, and dense electronic enclosures, the 9CRHA Series delivers up to 2700 Pa of static pressure—a 38% increase over previous models—without compromising airflow, speed or reliability.

Highlighted models, the 9CRHA0812P8J001 (12 VDC) and 9CRHA0848P8J001 (48 VDC), include PWM control with pulse sensor feedback to enable precision fan speed management across variable loads.

Frame Size: 80 × 80 × 80 mm

Rated Voltage: 12 VDC / 48 VDC

PWM Range: 20–100% (25 kHz)

Max Speed: 19,300 RPM

Max Airflow: 5.65 m³/min (199 CFM)

Max Static Pressure: 2700 Pa (10.8 inchH₂O)

Power Consumption: Up to 144 W (12 V)

Noise Level: 85 dB(A)

Expected Life: 70,000 h at 40°C

Protection: Locked rotor burnout, reverse polarity

Compliance: RoHS, UL 94V-rated materials, Eco Product certified

Operating Temp: -20°C to +70°C

These rugged, high-spec fans are available in both inlet and outlet configurations, offering design engineers greater flexibility for system-level cooling architecture.

EAO Ltd also offers thermal consulting, impedance curve analysis, and on-site airflow validation using Sanyo Denki’s advanced testing equipment.

Learn more and download the datasheet: https://motorsandfans.co.uk/sanyo-denkis-latest-san-ace-80-fan-delivers-exceptional-static-pressure-for-high-impedance-designs/

EAO Ltd is proud to announce the release of the Sanyo Denki San Ace 92 9AD Series, a cutting-edge range of compact AC cooling fans designed to deliver powerful, efficient and long-lasting thermal management in space-constrained industrial environments. These 92 × 92 × 25 mm axial fans are ideal for applications such as control panels, industrial equipment, power supplies and other systems requiring high-performance cooling under demanding conditions.

Standout models in the new range include the 9AD0901G4002, 9AD0901G4H001 and 9AD0901P4G001, which lead the pack in airflow and static pressure performance.

High Static Pressure: With a maximum static pressure of 76 Pa (0.305 inchH₂O), these fans deliver a 55% increase compared to the previous generation, making them ideal for high-resistance cooling environments.

High Airflow: Capable of delivering up to 1.34 m³/min (47.3 CFM), the 9AD Series offers a 21% airflow improvement, ensuring efficient heat dissipation in tightly packed enclosures.

Extended Service Life: The fans boast an impressive 90,000-hour lifespan at 40°C, more than double the life expectancy of legacy models, significantly reducing maintenance cycles and total cost of ownership.

Low Power Consumption: By reducing power use by up to 68%, the 9AD Series achieves outstanding energy efficiency without compromising on performance – ideal for companies focused on reducing their carbon footprint.

Advanced Control Options: Selected models include PWM control and low-speed sensor outputs, allowing for precise thermal management and intelligent fan control systems.

Rugged and Safe Design: Built with a UL 94V-0 flame-retardant plastic frame and impeller, the fans also feature locked rotor protection, dielectric strength and wide operating temperature support (-20°C to +70°C) for reliability in harsh industrial environments.

Sustainability & Compliance: Manufactured with lead-free brass and fully RoHS compliant, the 9AD Series is certified as an Eco Product Plus, aligning with the United Nations Sustainable Development Goals (SDGs).

Backed by EAO Ltd’s technical support – including impedance curve testing and airflow validation using Sanyo Denki’s portable test equipment – the San Ace 92 9AD Series is a powerful addition to any modern thermal management system.

For more information and to download the datasheet, please visit: https://motorsandfans.co.uk/new-sanyo-denki-san-ace-92-ac-fan-series-with-high-static-pressure-and-energy-efficiency/

EAO Ltd is pleased to introduce the latest additions to its Series 09 family of automotive HMIs - durable, IP67-rated sealed push-button switches designed for external use on heavy-duty vehicles such as municipal trucks, construction machinery, and agricultural equipment.

Specially developed for demanding, low-current, hard-wired applications, these robust switches are engineered to operate reliably in harsh environments and can be easily used while wearing gloves.

Typical Applications:

Key Features:

Built for long-term reliability and safety, the new Series 09 push-buttons are quick to install and help reduce maintenance downtime, ensuring smooth and safe operation across a wide range of vehicle platforms.

EAO Ltd also offers expert HMI guidance and application support to help ensure optimal vehicle integration.

Learn more: https://www.eao.com/en/series/09/series-09#cm9ihox0iettf07t58ruc6a67

EAO Ltd is excited to introduce the San Ace 200 9GA DC fan, a high-performance cooling solution from SANYO DENKI, ideal for GPU server heat exchangers, HVAC systems, and other high-demand thermal applications.

This ⌀200 × 70 mm model delivers the lowest power consumption in its class, using 36% less power than the previous model (9GV2048P0G201) while maintaining excellent airflow and static pressure performance.

Key Features:

Built with lead-free brass and RoHS compliant, the fan is certified as a SANYO DENKI Eco Product, supporting environmental initiatives including the UN SDGs.

Engineered for compact, high-resistance cooling environments, the San Ace 200 9GA is ideal for next-gen thermal designs.

EAO Ltd also provides expert support and airflow testing services using SANYO DENKI’s portable equipment.

EAO Ltd expands its Series 09 line-up with new Premium keypads, designed for safety-critical vehicle applications where functional safety, uptime and compliance are paramount.

The Premium keypads are engineered to meet and exceed the requirements of DIN EN ISO 13849, and have been independently certified by DEKRA Testing and Certification GmbH to achieve Performance Level D (PLd) in line with the Machinery Directive and ISO 13849-1.

Key Features:

The new Series 09 Premium keypads are ideal for systems requiring automated control of vehicle bodies or attachments—where safety, uptime, and efficiency are essential.

“The addition of the Premium Series 09 keypads strengthens both safety and reliability for vehicle operators while helping OEMs reduce development costs,” said Robert Davies, Marketing Manager at EAO Ltd. “Their robust design and certified architecture support more stable systems and better lifecycle value.”

Built to reduce operator risk and simplify compliance, these keypads provide a durable and intelligent HMI solution for next-gen automotive systems.

Learn more: https://www.eao.com/en/series/09/series-09#cm6gihqw0jnob07upbwm7ex6x

Series 82 – PCB Adapter for Easy and Secure PCB Assembly

The Series 82 now includes a new PCB adapter, designed to simplify and enhance the safety of PCB assembly. This addition complements the existing range of connection and mounting options, which include cable variants, M12 connectors, and standard plug and screw connections.

The PCB adapter provides a reliable and time-saving plug connection between the Series 82 pushbuttons and indicators and the printed circuit board (PCB). It is especially suitable for applications where Series 82 pushbuttons with 19- or 22-mm mounting cut-outs are integrated into larger control units or systems, alongside other components.

With this new adapter, the Series 82 further optimises installation processes, offering an additional option for specific applications, alongside the versatile connection solutions already available.

For more information please visit www.eao.com/en/series/82/series-82

SANYO DENKI has launched the San Ace 60L 9CRLB type Long Life Cooling Fan, a state-of-the-art solution designed to meet the demanding cooling requirements of network equipment and servers. This new 60 × 60 × 76 mm fan sets the industry standard with the highest airflow and static pressure, while offering an exceptional 100,000-hour lifespan under continuous operation.

Key features of the San Ace 60L 9CRLB fan include:

High Airflow: With a maximum airflow of 84.8 CFM, the fan provides a 14% increase over the previous model, ensuring optimal cooling performance for high-demand applications.

High Static Pressure: The fan offers a maximum static pressure of 6.0 inches H2O, representing a 7% improvement from the previous model, delivering superior performance in high-resistance environments.

Long Service Life: With an expected lifespan of 100,000 hours, equivalent to 11 years of continuous operation, this fan guarantees long-term, reliable cooling without the need for frequent replacements.

Energy Efficiency: The fan’s power consumption is reduced by 13% compared to the previous model, offering both operational cost savings and a reduced environmental footprint.

Eco-Friendly Design: Compliant with RoHS directives, the fan uses lead-free brass material and is certified as an Eco Product, supporting global sustainability goals.

Ideal for communication equipment and servers, the San Ace 60L 9CRLB fan addresses the growing need for high-performance, long-lasting cooling solutions in today’s data-driven world.

For more information, please visit https://motorsandfans.co.uk/140369-2/.

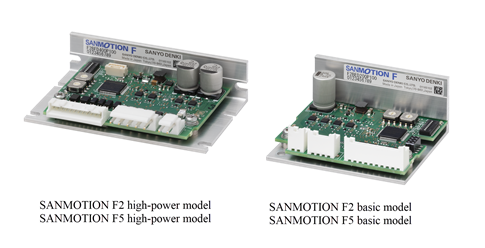

Sanyo Denki’s latest stepper motor drivers deliver advanced, lower-vibration control and the ability to drive higher torque motors, helping to contribute to reduced equipment positioning cycle times.

The F2B Series drivers are designed for 2-phase motors and include a high-power model, the F2BFD400P100, which supports phase currents from 3 to 4A—ideal for 56mm and 86mm motors. Both drivers have optional pre-wired connection cables for ease of installation.

With Sanyo Denki’s intuitive PC driver software, users can easily configure I/O signals, select current values, and set maintenance notifications. Enhanced safety features include overcurrent detection, abnormal power supply voltage monitoring, and excess temperature alarm signals, allowing for a safe motor stop when needed.

The F2BED200P100 driver offers a modern, mechanical mounting and signal-compatible plug-and-play replacement for the widely used BS1D200P10 stepper driver. It provides up to 33% lower vibration and a 39% reduction in weight.

Both drivers feature a versatile array of operating functions, including pulse input mode, resolution, low vibration mode, operating current, step angle, and current at rest.

Both drivers and all accessory cables are available from Farnell part numbers

F2BED200P100 2A version :4294527

F2BFD400P100 4A version: 4294528

Find out more about Sanyo Denki Motors at : MotorsandFans.co.uk

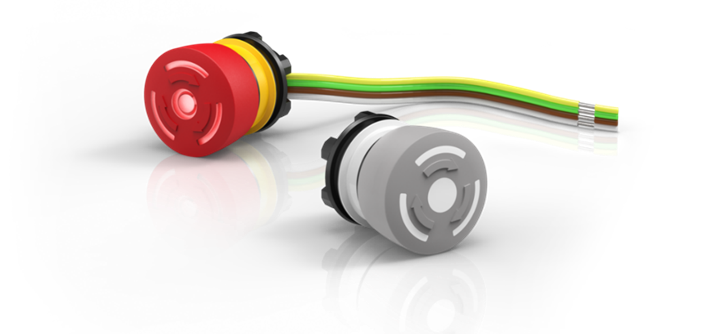

The second-generation Series 84 E-STOP and Stop Switches range now includes cable versions, that allow fast installation and simple connection, whilst the low 13.5mm depth make them ideal for equipment with limited back panel depth. Offering IP67 front sealing 1 or 2 switching contacts and optional illumination they are suitable for a wide range of industrial applications.

The versatility and robust design of the Series 84 E-STOP and Stop Switches make them ideal for numerous applications, including:

To meet stringent safety and quality standards, the Series 84 E-STOP and Stop Switches are certified with:

The Series 84 E-STOP and Stop Switches Generation 2 combines robust construction, modern design, and high reliability, making them an essential component for ensuring safety and performance in a wide range of applications.

To learn more about the products, please visit https://eao.com/en/series/84/series-84