Thanks to element14 and Kemet for selecting me as one of the ten chosen to receive the thermal switch kit for the Experimenting with Thermal Switches Design Challenge. In this first blog, I will detail a little bit about myself, my interest in thermal switches and my intended test plan.

Table of Contents

About Me

My name is Dr. Gough Lui and I am an engineer and electronics hobbyist from Sydney, Australia.

I currently work as a postdoctoral researcher in the Biomedical Engineering space with Western Sydney University and as a research assistant with Civil and Environmental Engineering in the University of New South Wales. I have an interdisciplinary background, which includes an undergraduate degree commencing in Electrical Engineering, finishing in Solar Photovoltaics Engineering with first-class honours and undertaking a Taste-of-Research in Spatial and Surveying Information Systems. I have a PhD in Civil and Environmental Engineering, specifically in Water Research. In my work, I support the design, assembly, testing and deployment of embedded electronics for applications in health, medicine and humanitarian fields.

Outside of work, I run my own personal blog site at https://goughlui.com where I blog about random things including product reviews, repair logs, computing, networking, retro-technology, radio, television, satellite, random observations and going on holidays. I am a licensed foundation-level radio amateur (VK2FGYL).

I have spent much time over the years at element14 as a Top Member, mostly lurking but occasionally responding to a comment here or there. I have benefited greatly from the RoadTest program which has yielded plenty of useful and interesting equipment for my bench. I have contributed a whopping 31 reviews as of this posting and have learned plenty from the experience. I have participated in a few Project 14 builds as well although not so much as of late. However, in all my time here, I have never participated in a Design Challenge … until now.

My Interest in Thermal Switches?

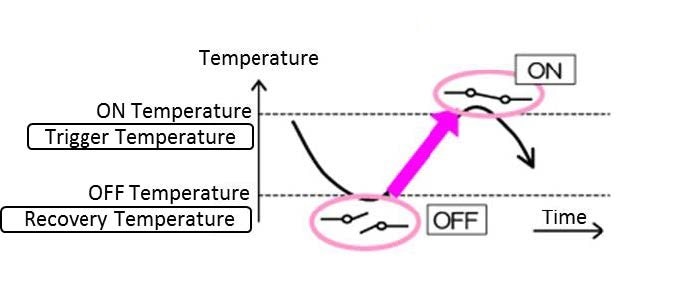

While taking apart equipment, it is not uncommon to come across some sort of thermal protection in the form of a one-shot thermal fuse, thermal switches or thermistor temperature sensors. Each of these serve a different purpose, with thermistors providing fine temperature information but also requiring supporting circuitry and proper signal interpretation. For the purposes of thermal protection, however, usually simple is best because such a system cannot afford to fail. One-shot thermal fuses are usually a last-line of defence for when everything has gone wrong and the device might be about to catch fire. Thermal switches, on the other hand, can be used to provide a binary on or off signal which indicates that a temperature threshold has been crossed. This can be used to regulate a heating element, switch an indicator light on, signal a microprocessor or control a cooling fan. As they act as a “self-contained” switch, they require very little circuitry to implement.

What piqued my interest in this Design Challenge was Kemet’s Thermolite® material in their TRS and OHD series thermal switches. Through smart application of material properties, specifically the curie point, they are able to create a temperature-sensitive magnetic reed switch. This has the benefits of better lifetime, fast response, low-current compatibility and potentially tighter temperature tolerances. I have seen similar switches before, but have never used them and was curious about the stability of their properties over time.

As I had spent a lot of time perfecting my automation techniques and have a cache of test equipment I could throw at the switches, I decided to apply for the challenge in the hopes that I could put my test equipment to good use and learn more about the performance of these products.

My Test Plan

As I have a wealth of test equipment, I proposed focusing on characterising the thermal switches provided in the kit. I will attempt to characterise as many as I can for the temperature cut-in and cut-out thresholds and temperature hysteresis over many cycles to see if there is any drift in parameters as the switch ages under a working load. Initial contact resistance and final contact resistance will also be measured in case this yields any further insights. Upon the conclusion of the tests, I may even repurpose the switches to create a simple temperature-controlled chamber by controlling a resistive heater, or to control heatsink temperatures by directly controlling a brushless-DC fan.

Image extracted from Kemet's "Which Thermal Sensor to Choose" guide.

The equipment to be used will most likely be my Keithley 2110 5.5-digit Digital Multimeter which will provide temperature measurements from a TME Electronics K-type thermocouple. While this is likely to give absolute temperature accuracy in the ballpark of 1.5 degrees Celsius, better measurements are not easily attained. This would be connected through a Raspberry Pi-based USB-TMC to LAN bridge and controlled using pyvisa from a Harting MICA Linux-based Industrial Computer for greater reliability and reduced power consumption compared to running my main Windows-based desktop. Alternatively, where multiple-channels are to be tested in parallel, I may consider using the B&K Precision/Sefram DAS240-BAT Multi-Channel Recorder as the data source with pymodbus (although I may not have enough K-Type thermocouples on hand – different units will introduce a new source of error so this may not be preferable). Power to the test apparatus can be supplied from any decent lab bench power supply, for now, I expect to use my Rohde & Schwarz HMC8043 (or HMP4040) mainly due to the number of channels available. To measure the contact resistance, I will use the Keithley 2450 SourceMeter SMU to source the maximum permissible current and measure the voltage drop in four-wire mode. This is subject to variation in case I do discover a better way to do things.

The switches themselves come in two types – the Normally Closed type (or break type) is perhaps the easiest to test. This is because it is possible just to have a resistor connected in series with the switch which will generate heat and once the thermal switch actuates, it cuts power to the resistor and the components will naturally cool. While this is straightforward, attention must be paid to the switching current and power limits of each model of thermal switch, which range from 0.1A to 0.55A. Likewise, attention needs to be paid to the thermal coupling between the components to ensure the temperatures are all equalised for accurate measurement. I propose that I wrap solid-core wire around the three components to provide thermal coupling in the simplest way, however, if this is not consistent enough, I may investigate adding thermal paste to the mix or immersion of the whole set-up in a liquid. Unfortunately, this may not be the intended way the manufacturer wishes the switch to be used, however, reed capsules are hermetically sealed so this shouldn’t cause any major issues. The bigger issue I can foresee is that the cool-down time may extend so far as to create very long cycle times, limiting my ability to test the change in actuation temperatures and hysteresis over many cycles.

Testing the Normally Open (or make type) is a little more complicated as it is an open circuit until reaching the threshold temperature. The least complicated way I can think of to test this is to have the heater resistor and the thermal switch in parallel, relying on the power supply’s current limiter to ensure the ratings are respected. However, I also know that there may be some output capacitance in the power supply, so current overshoot is almost unavoidable. Once the thermal switch shorts the input, however, the power supply should fold back to nearly zero-voltage thus the set-up should cool down of its own accord, opening the switch back up for another cycle.

That is particularly rough, however, perhaps with a SPDT relay in the mix, we can make things better. In this case, the relay’s normally closed contacts are used to drive a heater resistor – the value can be almost anything as long as the relay is able to handle it. This means faster heat-up is possible. Once the thermal switch closes, then the relay is turned on, disconnecting the heater resistor. The downside of this arrangement is the need for a relay, the need for a back-EMF snubber diode and the fact the current through the switch cannot be below the current needed for the relay coil. However, if more load is desired, then an additional load resistor can be added. An additional benefit which can speed testing is to use the normally open terminal of the relay to hook up a DC brushless fan to cool down the unit once it trips … so perhaps I will use a similar arrangement for both NO and NC type thermal switches.

The experiments will be monitored by a pyvisa script which I will have to write, however, the cycle times must be slow enough that the instrument can catch the switching point reliably, while also being fast enough such that I can achieve a reasonable number of cycles (hoping for >100,000 if possible). The switching point will be inferred from the power supply current measurement, to save the need for additional measurement channels. Overall, this arrangement will take some trial-and-error to achieve, and then the logged data must be analysed for the switching points and the trend over switching cycles can then be extracted.

Conclusion

I hope this posting has given you an insight into me, my interest in these unique thermal switches and the manner in which I propose to test them. Many of the finer details will be subject to trial and error once the test set-up has been built for testing as some ideas may not work as well as I expect. This might include using an actual heatsink for moulded sensor products for better thermal coupling, oil or liquid immersion for other products. However, I do think that the test plan is achievable and should be able to automatically collect data over time that will allow me to understand the cut-in, cut-out, temperature hysteresis as the unit ages. Measurement of contact resistance before and after testing will be undertaken, which may reveal something about the quality of the contact after it is cycled. Upon the completion of these experiments, I will also try repurposing some well-rated switches to perform simple “keep-warm” or thermostatic-controlled heatsink fan type applications.

I hope you will join me in the next blog, where I will hopefully have the sensors in hand, be building the test set-up and revealing the results of these experiments. How well will the Kemet switches hold up to continuous cycling? Only one way to find out ...

[The Torturing Thermal Switches Blog Series Index]

- Blog #1: Torturing Thermal Switches – Cycle Testing Cut-in, Cut-out, Hysteresis & Contact Resistance (this post)

- Blog #2: Torturing Thermal Switches – Unboxing, Initial Characterisation & Experimental Refinements

- Blog #3: Torturing Thermal Switches – Magnetic Characteristics, Teardown, Overload Behaviour & Commencing the Cycle Experiment!

- Blog #4: Torturing Thermal Switches – Contact Bounce, Overvoltage & Building a Component/Filament Dryer

- Blog #5: Torturing Thermal Switches –Temperature Measurement Complexities, Switching Deviations, Data Analysis & Interim Results

- Blog #6: Torturing Thermal Switches – Latching Fault Circuit Design, Weighing In, and Checking Contact Resistance

- Blog #7: Torturing Thermal Switches – A Minor Glitch, *Final* Results & Conclusion

Top Comments