Previously, I blogged about officially beginning my proposed thermal switch torture experiment. In that posting, I explored some other subtle forms of torture, including with magnets and by deliberately overloading the switch by exceeding the rated current. That post was rather positively received, spawning a few questions which I explore more closely in this post along with a simple build. After all, the cycle experiment is going to take a whole month and a half (or whatever time remains at the time you come to read this), so might as well do something interesting in the interim.

Table of Contents

Vibration Induced Resonance

An element14 member (javagoza) asked in the previous posting whether acceleration or deceleration, or strong vibrations could affect these switches. This is, in fact, something I had wanted to find out for myself and had already gone some way into attempting to test. It is a habit of mine to collect test data which I keep until I have the time to write-up into a posting, but rather than leaving everyone in the dark, I did provide a sneak preview in a reply comment.

A reed switch can be thought of as two “flexible” thin Fe-Ni metal bands (reeds) encased inside a glass capsule such that they sit apart by a small gap. An external magnetic field acts on the contact tips which allows them to connect, closing the circuit. In the case of the thermal switch, this field is provided by annular magnets, modulated by the engineered Curie-point Thermolite material.

Because of the mass of the material at the contact tips and the flexing nature of the contacts, it is expected that this arrangement will exhibit sensitivity to vibration and shock, especially if it is applied in such a way to cause the contacts to flex in their natural opening/closing direction. Furthermore, such an arrangement can also resonate if excited at the right frequency.

This possibility is acknowledged by Kemet, at least in the full form datasheet of the TRS Thermal Reed Switch, Screw Type which states the following points under Handling Precautions – “Do NOT use if dropped or severely shocked. Thermal Reed switches have a specific resonance frequency. Please contact a KEMET representative if an oscillation is added[sic].”

As the data is not posted, I had to think about how I could test this. I don’t have access to a vibration testing table that could sweep the frequencies, but I did have a think about how I could probably improvise one. Looking around my room, I found an old subwoofer driver, but then I realised mounting a thermal switch to the subwoofer wouldn’t work because it generates a modulated magnetic field inside a static magnetic field in order to move (i.e. voice-coil motor) which would in itself affect the switch. I could improvise something to increase the distance to the thermal switch, but I feared the added mass would reduce the frequency response and displacement achievable from the driver.

This is when I decided to just do things simply. Remembering the principles behind the Fourier transform, a sharp impulse is essentially a square wave containing a theoretically infinite series of sine waves. If the system is resonant with a dominant resonance and a decent Q-factor, then it will act like a filter, instead ringing at the resonant frequency. In fact, this is in some way just like how a quartz oscillator starts up. However, I do realise that the resonance of the component may be much more complex than a single dominant frequency and will depend on reed/switch geometry, material flex and weights. At least the experiment should provide some preliminary data about the dominant resonant frequency.

As a result, I chose to hook up break-type switches of varying package types to my Keithley 2450 SMU set to 1V/1mA while it was observed by the Rohde & Schwarz RTM3004 Oscilloscope. I set the trigger to a sensible value for a single-shot acquisition before getting out a flat-head non-magnetic screwdriver and tapping the case of the thermal switch sharply with increasing force until a trigger (indicating a switching event) was observed.

OHD1-30B

At first glance, this oscilloscope trace may seem strange given the settings on the SMU. Instead, it is an illustration of how the thermal switch is oscillating so quickly that the SMU is struggling to keep up (in a regulated way), hence the voltage exceeds the 1V set-point frequently.

Regardless, the pulse train seems to be semi-regular to begin with, exhibiting a frequency about 14.7kHz. Multiple resonances may be at play, as this then devolves into a few more closely-spaced pulses, before becoming an irregularly spaced train of multiple pulses which are in the ~3kHz region. An encouraging observation was that the case needed to be struck directly for this to happen – a glancing blow onto the wire leads didn’t prove sharp enough.

OHD5R-90B

Trying the same with the smaller OHD5R type switches, the oscillations seem to come faster at roughly twice the frequency – 30.8kHz. This is probably a result of the smaller contacts but suspended on a reed of similar stiffness.

M-TRS5-30B

The bulkier M-TRS5 type switches weren’t easy to tap into resonance and when they did, they seemed to be dominated by a slow oscillation at about 1.4kHz with the repeated pulses towards the end approaching the 50kHz range. This is perhaps because of the mass of the switch compared to the other case types serving to dampen the initial impulse, or perhaps due to the alignment of the stimulus and the reed, as the circular switches don’t have a “defined” top surface.

TRS1-120BPR001

The screw-type metal-cased TRS1 was even more difficult to jostle into resonance and required a sharp blow. The resonance did not last long either – dying away after two cycles in this case. The frequency is about 13.9kHz, but the result may differ depending on how you “tapped” the case. I had quite a few unsuccessful attempts with this one.

TRS5-30BLR00

Finally, the leaded type was tested, with a bit of an unusual pattern – initially starting as if a regular oscillation were established, which then became “dead”, followed by later “regular” oscillations after a delay. Perhaps the contacts had somehow “stuck” because I struck the switch too hard, but the more stable oscillation towards the end was about 11.4kHz.

In most measurements, the main resonance frequency seems to be a relatively high frequency and the chances of a powerful vibration at such high frequencies seems relatively unlikely. I don’t foresee this to be a major barrier to application of these switches.

State Transition Contact Bounce

As the reed switch is an electromechanical device, just like any other switch, it will probably exhibit contact bounce on a state transition. As some of my other switches were tied up in the cycle testing and in the build presented later in this post, I decided to test this out on the M-TRS5-30B in the summer evenings when the switch can stay closed.

To open the switch, all it takes is holding the switch between the fingers and body heat can do the rest. The opening is quite clean and the response shown is actually that of the SMU which has about 25us regulation time.

To close the switch, instead of waiting for the air to slowly bring it down enough, I used an inverted air duster can to rapidly cool the switch. The switch then closes, but with noticeable bounce lasting about 200-250us.

Given the electromechanical nature of the switch, I decided to repeat the experiment and was pleased to see that I had almost an identical result. In some sensitive applications, switch debouncing is probably a good idea.

Overvoltage Behaviour

Last time, I explored overcurrent, so this time, I will explore overvoltage. The thermal reed switches consist of contacts inside a glass envelope, however, for better contact lifetime and switching performance, this envelope is often filled with an inert gas which serves to improve the voltage rating and reduce arcing.

For the range of KEMET Thermal Switches we have received, their switching voltage ratings are as follows – 30V, 100V, 110V, 140V and 200V with differences between AC and DC ratings for some models.

To test whether these ratings would be realistic, I decided to perform an insulation resistance test using the Keysight U1461A Insulation Resistance Test Multimeter. It essentially provides a current-limited (1mA ideally) high-voltage (up to 1000V) DC supply. Tests were only done on the make-type switches as they are open by default at room temperature.

Testing on a variety of switch types seems to suggest that breakdown occurred when testing at 1000V and an internal arc was sustained across the contacts and fill-gas with a voltage of about 200V. This seems to suggest that a 200V rating is realistic, as breakdown requires over-voltage to occur.

Connecting the U1461A and switch combination to my Micsig DP10007 High-Voltage Differential Probe and RTM3004 oscilloscope, it seems breakdown occurred after the voltage reached 1kV.

Testing at the lower voltage of 500V showed no breakdown effect, reconfirming that the switches are sufficiently designed to handle the rated values, perhaps even slightly more. The value of 10MΩ displayed actually reflects the impedance of the high-voltage differential probe attached to the switch at the time, indicating that the switch had an even higher effective impedance.

Testing of some switches under a few repeated breakdowns seem to show the arc voltage increased until it because >1000V DC. This suggests to me that even an overvoltage sufficient to arc at 1mA current limit may have dissipated enough energy in the thermal switch that the reed capsule may have been breached and vented its gas to atmosphere. As a result, the switch reliability may be impeded by contamination and thus, this unit has been “retired”.

Designing and Constructing a Component/Filament Dryer

Remember how I didn’t devote both of my 50°C and 60°C switches to the cycle torture experiment? This is because I had some plans for them, as it might be nice to have a “warm” box for various reasons such as drying out 3D printing filament or components which have absorbed moisture and need to undergo reflow soldering. As a result, I will reveal the simple design I have made along with some test results.

Design

I decided up-front to use the thermal switches but no microcontrollers. I decided to keep everything simple and perhaps even electromechanical. The design would use the thermal switches to produce the necessary control signals to control relays that would be responsible for the heating. The heating would come courtesy of 1 to 3 12V 50W Halogen Dichroic MR16 lamps, with the air circulated by a 120mm brushless DC computer fan.

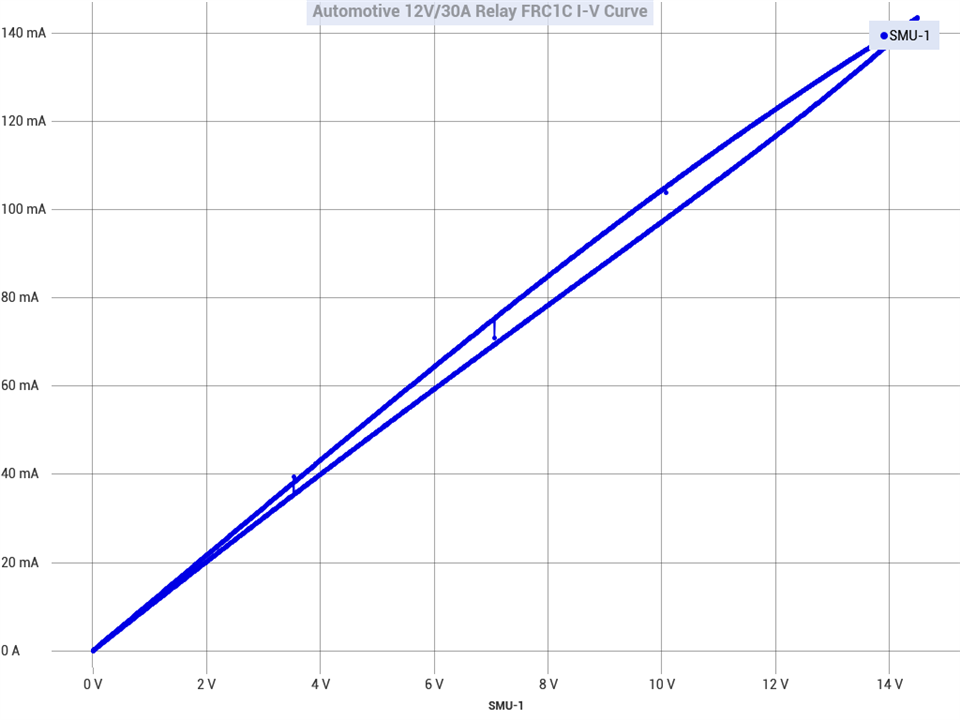

As the lamps themselves would be rather heavy load (150W at 12V would be 12.5A) and the temperature differential (hysteresis) of the switch can be relatively small, I needed a relay which could both handle the current and also frequent switching. For this, I rummaged my junk box and found the FRC1C.

This is an automotive headlight or horn changeover relay. Such a unit is usually rated for 30A current and is relatively hardy. But will it be driven by the thermal switches which have a current limit of just 300mA?

A quick I-V curve trace using KickStart 2 and the Keithley 2450 SMU showed me that it would easily fit inside the current limits, so that is great news. That is one part added to the list.

The next thing I thought of was safety – what if this relay or the thermal switch were to weld and keep the heat on forever? That would not be good news! As a result, I decided to employ another thermal switch and relay that will act as a safety. This relay will only switch out in case of overheating, thus I used the smaller and lesser rated Tianbo TRA2 relay as it should still handle the continuous current of the lamps but without much margin. Using the TRA2 for the heavily switched relay may be possible, but I usually prefer to de-rate those components so that they might last a bit longer. The safety was chosen to be a 90°C make-type switch instead, so I have a mix of break and make-type switches in the design. I would have preferred a lower temperature, but the provided kit did not have any switch in-between 60 and 90°C.

The schematic of what I intended to build is shown above. The 9V relay is being used on 12V, so I added a dropper resistor to take the extra voltage. Indicator LEDs for heating, power and fault have been added to the design as well. A switch allows for the 50°C thermal switch to be shorted out so that the unit cycles around 60°C instead. When operating at 50°C, the 60°C acts as a safety for a failure of the 50°C switch welding shut but not for a relay failure where it too is welded shut. The 90°C protects against this failure condition. Where the switches are stuck open, then heating will not occur. The safety could fail, however, if the contacts somehow weld closed but as that switch is not expected to see many cycles, the probability is quite low. Relay coils back-EMF protection is provided using ordinary 1N4004 diodes. The fan is always powered to keep air circulating and help keep things cool. Quite self-explanatory.

There is one consideration to be made, however, regarding switching lifetimes. Such a use of thermal switches can result in short cycles and many switching events occurring, rapidly exhausting the lifetime of switching elements. While the thermal switching reed may have a 500,000-cycle nominal lifetime, the reliance on relay switching realistically adds a 10,000-cycle nominal switching lifetime limit – if the thermal switch did one cycle per minute, this would be exhausted in just seven days of operation. This is why designers need to consider the switching rate and the “weakest link” in the chain – it’s no good having a thermal switch that can have a long switching life if it is driving something that is not able to keep up! However, switching at once-per-minute would exhaust the thermal switch lifetime in about a year of operation, so perhaps for such regulation operation, use of thermistors, thermocouples or RTDs and intelligent controllers is still more suited.

Build

Such a build is relatively straightforward, so I went right at it using a scrap of Veroboard without any planning whatsoever. This resulted in a slightly haphazard layout including the unusual mounting of the relay.

The switched output goes to the Wago terminals for quick connection to MR16 pin bases. The power input is terminated in spade sockets to be connected to a banana terminal. The brown wire is 2.5mm2 to ensure sufficient current carrying capacity. The lack of wire colour coding is primarily because I use what is on my bench, and that is usually whichever colour spool is on sale at element14 (yes, I still have about 90m of the brown stuff left)! The fan output is to a terminal block in case the fan fails and needs to be replaced.

As the copper on the Veroboard is probably not ideally suited to high currents, I’ve attached the wires directly to the back of the safety relay contacts and flooded solder all over the board, also taking up an adjacent track for mechanical support. Such an arrangement should ensure low resistance.

The whole set-up was placed inside a cardboard box for testing. Cardboard was chosen as its corrugated nature should provide some insulation by virtue of holding a layer of air within it, and it was a readily available material that would not burn at the anticipated test temperatures.

Test

During testing, my very messy room looked a bit like this:

That’s a lot of equipment working at the same time … thankfully there was enough of it to allow me to run both tests at the same time. This time around, I called on the Aim-TTi QPX750SP Power Supply to provide the grunt while the Keithley 2110 5.5-digit DMM did the measuring.

In order to do the temperature logging, I wrote a simple program that spoke to the 2110 via my Raspberry Pi USB-TMC to Ethernet bridge.

# Data-Logging Temperature from Keithley 2110 DMM

# via USB-TMC to Ethernet LAN Bridge

# by Gough Lui - February 2022

import visa

import time

resource_manager = visa.ResourceManager()

ins_k2110 = resource_manager.open_resource("TCPIP0::192.168.xxx.xxx::5025::SOCKET")

ins_k2110.read_termination = "\n"

print("Available:" + "\n" + ins_k2110.query('*IDN?'))

print('Setting Up - K2110')

ins_k2110.write('FUNC "TCO"')

ins_k2110.write('TRIG:SOUR BUS')

ins_k2110.query("*OPC?")

# Begin Voltage Experiment

print("Begin Logging")

data_log = "k2110-templog.csv"

f = open(data_log,"a")

try:

while True :

ins_k2110.write('INIT')

ins_k2110.write('*TRG')

read=0

while read != 1 :

try :

mmbaseline = ins_k2110.query_ascii_values('FETC?',separator='\r')

except :

print("Retrying read!")

continue

else :

read=1

f.write(str(time.time())+","+str(mmbaseline[0])+"\n")

f.flush()

except KeyboardInterrupt :

print("Aborted!")

f.close()

ins_k2110.close()

print("Script Completed!")

With just two lamps and running at 50°C, the graph looks as follows:

The unit maintained temperature between 43°C and 52°C. While the switch may have tighter tolerances, the positioning of the switch, thermal mass, rate of change of temperature and airflow would have had an impact. The temperature averaged about 47.5°C which is quite suitable for drying PLA. The cycle time was approximately 2.5 minutes and could probably be improved with better insulation.

Shorting out the jumper to put the unit into 60°C mode, the graph looks as follows:

In this test, boosting the voltage to the two lamps was necessary to ensure enough heat was developed before it was lost out of the box. The unit maintained temperature between 46°C and 62°C. This temperature seems to overlap quite a bit with the range of temperatures obtained in the 50°C mode and could be possibly due to the larger switch which may have some thermal mass, delaying its response to the rapid declining temperature. The cycle time in this case is just above 3 minutes.

To test the overtemperature protection, I decided to add one extra lamp to bring the unit to 150W at 12V and pump the voltage up to 14.5V which increased the power output to 200W. This was necessary as otherwise, the heat developed would be lost so quickly out of the relatively flimsy cardboard box that it would never get up to the overheat protection temperature.

While it did eventually reach the temperature and cycle at near 90°C, it was not without strong protests from the brushless DC fan which is probably only rated for operation up to 60 or 70°C. It began to squeak and rattle loudly as if it had a bearing failure, probably because parts have expanded more than expected and lubrication may have failed in some way. Thankfully, nothing failed or seemed permanently harmed …

… except for this 3D-printed drawer which I left inside the box as an experiment with annealing 3D prints. It certainly annealed somewhat … resulting in a shrink in the X and Y directions causing the edges to bow inward and the print to curl upwards slightly. Good proof of the temperatures achieved inside the “warm” box.

A Quick Redesign?

To make the design more resilient, it would be easy to change out the overheat protection thermal switch for a lower temperature rating. The weakness of electromechanical relays can be overcome by replacing them with solid-state relays …

… or even N-channel MOSFETs which have very low Rds values, and hence, a negligibly small amount of self-heating. While I did not build the above schematic, I do expect it should function just fine.

However, there is one note to the design and this is the need to respect the minimum current rating for the thermal switch contacts. Just like relays, the contacts can develop oxide layers which can result in issues with small signals not “clearing” or puncturing through the oxide resulting in high-resistance connections or crackles. As a result, having sufficient “sealing” current would serve to clean the contact and ensure a good connection, so adding a load resistance may be necessary to bring the current through the contacts up to the 1mA minimum.

Thoughts About Switching Inductive Loads

Before I finish this blog, I thought I would address a comment made by another element14 member (robogary) who wanted to understand how the switches would hold up to an inductive load without snubbers.

I did have a think about this and found it rather difficult to come up with a test that would respect the ratings for the switches. In all, the switches have the following maximum ratings that need to be respected:

- Current ratings are 0.1A, 0.3A, 0.5A or 0.55A.

- Voltage ratings are 30V, 100V, 110V, 140V and 200V (with differences between AC/DC on some models).

- Power ratings are 1W, 6W, 10W and 60.5W (with differences between AC/DC on some models).

Because of the voltage ratings, mains-based experiments seem out of the question but low-voltage AC and DC is an option. However, as there is no specific derating values or references to inductive/capacitive loads in the datasheets I’ve seen, it’s hard to know if I am respecting the manufacturer’s intentions. I would suspect generic relay derating values would apply which could cut the current ratings significantly (by 3x or 10x).

While I could just attach an inductor to the output, I feel such testing is hard to abstract to more generalised findings which could apply to other use scenarios. This is because the specific nature of the inductive circuit and the point of switching will have a big impact on the actual current flow and potential for contact damage. It would not be something that would be easily measured on a continuous basis. It would also require that I build another separate rig that would thermally cycle the switch while monitoring it. As my cycle experiment (the only one I proposed) is running well, I am reluctant to disturb it!

As a result, while I do acknowledge that inductive loads will have inrush effects that would affect the switches, I think applying relay-based derating values would be sensible. But even without this, the indication that short-term inrush seems to be accounted for seems to be in-line with the overcurrent measurements in the previous blog, so I do suspect that there is some margin that can be exploited although this may be at a cost to overall lifetime. In the end, perhaps this is something best left to a proper test lab …

Conclusion

In this blog post, I tortured thermal reed switches by banging on them with a screwdriver to assess their mechanical resonance, looked closely at switch bounce with an oscilloscope and subjected them to gross overvoltage to determine their arcing voltage and rough breakdown voltage.

Instead of just torturing the switches, my diversion had me designing and building a simple “warm box” for drying out filament or components. The design involved consideration of the reliability of electromechanical switching components – especially in case you use relays with the thermal switches, as they will often have lower switching lifetimes. Upgrading to solid-state switching may be a sensible choice, however, respecting the minimum switching current is advisable to avoid contact oxidation issues causing poor switching. It also involved consideration about safety in case of a switch failure, thus having a back-up option would be considered wise. In the end, the “warm box” was built and worked as expected, revealing that brushless DC fans don’t like temperatures above 70°C and that PLA+ models can be annealed by such temperatures.

That brings us to the end of this blog. Perhaps the next blog in the series will look at the cycle experiment intricacies as to why the switching temperature seems a bit low, the issue of thermal conduction and perhaps even an interim peek into the results gathered so far. Hope to see you in the next one, but in the meantime, feel free to leave a comment in case you have any questions or ideas!

[The Torturing Thermal Switches Blog Series Index]

- Blog #1: Torturing Thermal Switches – Cycle Testing Cut-in, Cut-out, Hysteresis & Contact Resistance

- Blog #2: Torturing Thermal Switches – Unboxing, Initial Characterisation & Experimental Refinements

- Blog #3: Torturing Thermal Switches – Magnetic Characteristics, Teardown, Overload Behaviour & Commencing the Cycle Experiment!

- Blog #4: Torturing Thermal Switches – Contact Bounce, Overvoltage & Building a Component/Filament Dryer (this post)

- Blog #5: Torturing Thermal Switches –Temperature Measurement Complexities, Switching Deviations, Data Analysis & Interim Results

- Blog #6: Torturing Thermal Switches – Latching Fault Circuit Design, Weighing In, and Checking Contact Resistance

- Blog #7: Torturing Thermal Switches – A Minor Glitch, *Final* Results & Conclusion

Top Comments