2. Delta Solivia protocol description

Messages on the RS485-bus look like this:

| Size | Name | Value | Description |

| 1 byte | STX | 0x02 | Start of message |

| 1 byte | ENQ | Enquiry type (0x05 for requests, 0x06 for responses) | |

| 1 byte | Inverter ID | ||

| 1 byte | LEN | Number of bytes to follow, excluding CRC and ETX | |

| 2 bytes | CMD | command and subcommand e.g. 0x10 0x02 to request the current DC voltage, 0x10 0x02 to request the current DC current, etc. | |

| LEN-2 bytes | data bytes | ||

| 2 bytes | CRC | CRC-16, over preceding bytes excluding STX, LSB first (little-endian) | |

| 1 byte | ETX | 0x03 | End of message |

| Request | Response | Value | Meaning |

| [02][05][01][02][00][01][AD][FC][03] | [02][06][01][0C][00][01][30][30][30][30][30][30][37][38][39][34][2D][D0][03] | 0000007894 | Serial number |

| [02][05][01][02][10][02][E0][3D][03] | [02][06][01][04][10][02][01][88][32][E7][03] | 0x0188 | DC voltage (actual) |

| [02][05][01][02][11][02][E1][AD][03] | [02][06][01][04][11][02][01][78][33][5F][03] | 0x0178 | DC voltage (average) |

|

[02][05][01][02][10][01][A0][3C][03]

|

[02][06][01][04][10][01][00][09][03][17][03] | 0x0009 | DC current (actual). Unit is 0.1 A |

|

[02][05][01][02][11][01][A1][AC][03]

|

[02][06][01][04][11][01][00][05][02][EE][03] | 0x0005 | DC current (average). Unit is 0.1 A |

|

[02][05][01][02][11][03][20][6D][03]

|

[02][06][01][04][11][03][00][D7][23][73][03] | 0x00d7 | DC power |

|

[02][05][01][02][21][04][75][AF][03]

|

[02][06][01][04][21][04][07][D0][DE][40][03] | 0x07d0 | Isolation (actual, MOhm) |

|

[02][05][01][02][11][0F][20][68][03]

|

[02][06][01][04][11][0F][07][DA][20][85][03] | 0x07da | Isolation (average, MOhm) |

|

[02][05][01][02][10][08][60][3A][03]

|

[02][06][01][04][10][08][00][EC][12][9E][03] | 0x00ec | AC Voltage (actual) |

|

[02][05][01][02][11][08][61][AA][03]

|

[02][06][01][04][11][08][00][EA][93][60][03] | 0x00ea | AC Voltage (average) |

|

[02][05][01][02][10][07][20][3E][03]

|

[02][06][01][04][10][07][00][11][E3][1C][03] | 0x0011 | AC current (actual). Unit is 0.1 A |

|

[02][05][01][02][11][07][21][AE][03]

|

[02][06][01][04][11][07][00][0B][63][2B][03] | 0x000b | AC current (average). Unit is 0.1 A |

|

[02][05][01][02][10][09][A1][FA][03]

|

[02][06][01][04][10][09][01][72][C3][66][03] | 0x0172 | AC power (actual) |

|

[02][05][01][02][11][09][A0][6A][03]

|

[02][06][01][04][11][09][00][EE][C3][63][03] | 0x00ee | AC power (average) |

|

[02][05][01][02][21][06][F4][6E][03]

|

[02][06][01][04][21][06][00][1B][3C][27][03] | 0x001b | DC NTC Temperature |

|

[02][05][01][02][20][05][B5][FF][03]

|

[02][06][01][04][20][05][00][18][8D][DA][03] | 0x0018 | AC NTC Temperature |

| [02] | STX |

| [05] | ENQ |

| [01] | Inverter ID |

| [02] | Number of data bytes |

| [21][06] | Command and subcommand (DC NTC Temperature in this case) |

| [F4][6E] | CRC-16 |

| [03] | ETX |

| [02] | STX |

| [06] | RESPONSE |

| [01] | Inverter ID |

| [04] | Number of data bytes |

| [20][06] | Command and subcommand (the same of the request) |

| [00][1B] | 16-bit value of the requested parameter |

| [3C][27] | CRC-16 |

| [03] | ETX |

| Request | Response | Value | Meaning |

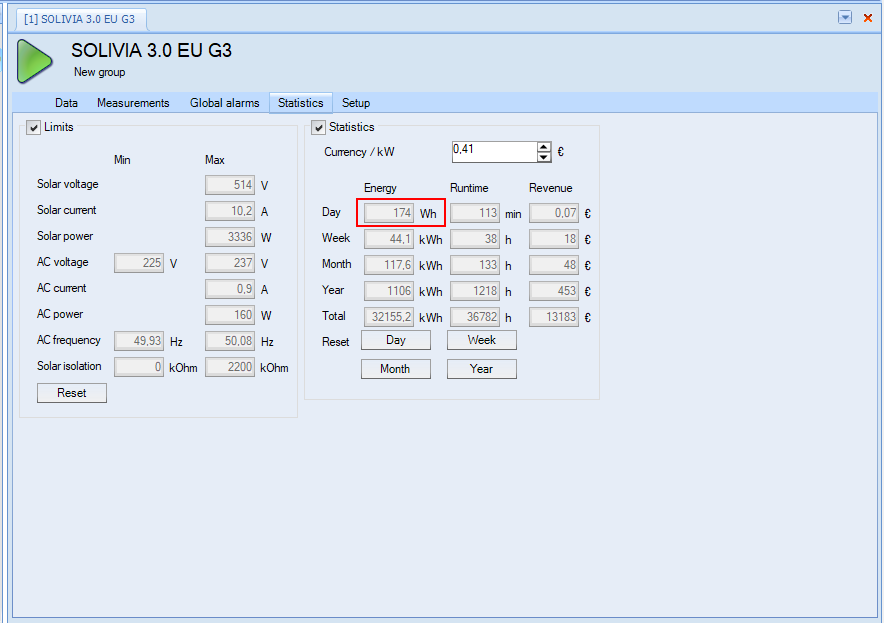

| [02][05][01][02][13][03][21][0D][03] | [02][06][01][04][13][03][00][AE][E3][29][02] | 0x00AE (174) | Daily yield (Wh) |

To implement the Delta Solivia protocol, I started from this project. I had to make some changes to use python3 (the library was written to support python2) and to use the correct commands.

Here is a brief description of the functions involved

3.1 solivia_readData

This function reads a specific value from the Delta Solivia inverter (DC power, AC power, etc). The only caveat here is that I had to add a check to remove some trailing 0xff characters that are probably mistakenly read by the USB-to-RS485 converter when inverter drives RS485 from RX to TX.

def solivia_readData(s):

log.debug("Reading %s"%(s))

cmd = solivia_inverter.getCmdStringFor(s)

log.debug("Command: %s"%binascii.hexlify(cmd))

solivia_connection.write(cmd)

rawResponse = solivia_connection.read(100)

cntr = 0

while (cntr < len(rawResponse) and rawResponse[cntr] == 0xff):

cntr += 1

response = rawResponse[cntr:]

floatValue = float("0")

if response:

log.debug("Received response %s\n"%binascii.hexlify(response))

value = solivia_inverter.getValueFromResponse(response)

#log.debug("Value %s"%value)

if solivia_isFloat(value):

floatValue = float(value)

return floatValue

The code leverages functions in the deltaInv.py file to extract a value as a floating point number from the inverter response

3.2 solivia_updateChannel

This function updates all the Modbus registers required to mimic one of Omega OM240 channels. The following Modbus registers are initialized

- 2 16-bits registers with the value

- 8 16-bits registers with the timestamp string

- 1 16-bits registers with the flags

Here is the code

def solivia_updateChannel(ch, value, ts):

""" Registers are as follow

0-1 Input A (IEE754)

2-3 Input B

4-5 Temperature

6-14 Timestamp "dd/mm/yy hh:mm:ss"

15 Flags

"""

vHex = solivia_floatToHex(value)[2:]

log.debug("value=%f, vHex=%s"%(value,vHex))

stime = ts.strftime("%d/%m/%y %H:%M:%S").encode('utf-8').hex().ljust(36, '0')

values = [int(vHex[0:4],16), int(vHex[4:8],16),

0, 0,

0, 0,

int(stime[0:4],16), int(stime[4:8],16), int(stime[8:12],16), int(stime[12:16],16), int(stime[16:20],16), int(stime[20:24],16), int(stime[24:28],16), int(stime[28:32],16), int(stime[32:36],16),

3]

return values

3.3 solivia_reader

This functions reads all the measures and update the corresponding channels

def solivia_reader(a):

""" A worker process that runs every so often and

updates live values of the context. It should be noted

that there is a race condition for the update.

:param arguments: The input arguments to the call

"""

log.info("Updating inverter data\n")

dcVolts = solivia_readData('DC Volts1')

dcCur = solivia_readData('DC Cur1')

dcPow = solivia_readData('DC Pwr1')

acVolts = solivia_readData('AC Volts')

acCur = solivia_readData('AC Current')

acPow = solivia_readData('AC Power')

acTemp = solivia_readData('AC Temp')

dcTemp = solivia_readData('DC Temp')

context = a[0]

register = 3

slaveId = 0x00

address = 0

values = solivia_updateChannel(0, dcPow, datetime.now())

context[slaveId].setValues(register, address, values)

address = 16

values = solivia_updateChannel(0, acPow, datetime.now())

context[slaveId].setValues(register, address, values)

address = 32

values = solivia_updateChannel(0, acTemp, datetime.now())

context[slaveId].setValues(register, address, values)

address = 48

values = solivia_updateChannel(0, dcTemp, datetime.now())

context[slaveId].setValues(register, address, values)

currDate = datetime.now().strftime("%d/%m/%y").encode('utf-8').hex().ljust(10, '0')

currTime = datetime.now().strftime("%H:%M:%S").encode('utf-8').hex().ljust(8, '0')

log.debug(currDate+"-"+currTime+" %.6f %.6f %.6f %.6f %.6f %.6f %.6f %.6f OK\n" %(dcVolts, dcCur, dcPow, acVolts, acCur, acPow, dcTemp, acTemp ))

log.info("Scheduling task")

time = 5.0

loop = LoopingCall(f=solivia_reader, a=(context,))

loop.start(time, now=True) # initially delay by time #!/bin/sh

# launcher.sh

# navigate to home directory, then to this directory, then execute python script, then back home

cd /home/pi/nmodbus

sudo python3 server.py

cd /

# Edit this file to introduce tasks to be run by cron.

#

# Each task to run has to be defined through a single line

# indicating with different fields when the task will be run

# and what command to run for the task

#

# To define the time you can provide concrete values for

# minute (m), hour (h), day of month (dom), month (mon),

# and day of week (dow) or use '*' in these fields (for 'any').

#

# Notice that tasks will be started based on the cron's system

# daemon's notion of time and timezones.

#

# Output of the crontab jobs (including errors) is sent through

# email to the user the crontab file belongs to (unless redirected).

#

# For example, you can run a backup of all your user accounts

# at 5 a.m every week with:

# 0 5 * * 1 tar -zcf /var/backups/home.tgz /home/

#

# For more information see the manual pages of crontab(5) and cron(8)

#

# m h dom mon dow command

@reboot sh /home/pi/launcher.sh >/home/pi/logs/server.log 2>&1