Take the Poll | Join our Discussion

sponsored by

Keeping a Smart Factory Connected

With the growth of Industry 4.0 and the increasing convergence of operations technology (OT) and information technology (IT), the issue of connectivity steps to the forefront. In order to evolve from a linear, sequential supply chain operation to an intelligent and interconnected digital supply network, a versatile, secure, and reliable connection system, capable of delivering a constant stream of data, is an essential building block. Additionally, the connection system must be robust and able to withstand the impacts and vibrations common to the factory floor. Euro-style terminal blocks have become ubiquitous because of their reliability and versatility; however, some of the more demanding factory environments can expose weaknesses in these solutions.

What Is a Euro-style Terminal Block?

A terminal block is an insulated housing containing connectors that have a mechanism for fastening two or more wires. Because terminal blocks require no soldering, they are ideal for applications that require semi-permanent wire connections, which can be easily swapped out. There are several types of terminal blocks, including Euro-style, barrier strip, and feed-through.

A Euro-style terminal block (also referred to as wire-to-board) is a PCB mount terminal block. In a Euro-style terminal block, bare wires are connected to a module containing a clamp. When the clamp is engaged, the wire is secured in the housing. The clamp can be easily disengaged, simplifying the removal of the cable for inspection or repair in the field. Euro-style terminal blocks are soldered onto PCBs, and are available in several form factors.

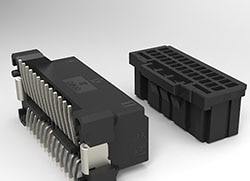

Figure 1 illustrates various examples of Euro-style terminal blocks and connectors.

Figure 1: Euro-style terminal blocks

Source: TE Connectivity

Euro-style terminal blocks are cost-effective, reliable, and enable a large number of connections in a small space. However, the typical jostling and mechanical vibrations common to industrial applications can make even a well-secured terminal block connection start to show its weaknesses.

The Challenges of Vibration

The environments of many factories are extremely harsh, and industrial connectors must be robust enough to handle them. Industrial connectors are susceptible to a variety of conditions, including mechanical stress, vibration, high-pressure liquids, and chemicals.

Motorized equipment often vibrates, especially when the components within begin to deteriorate. The rapid back and forth oscillation makes noise, causes further degradation, and eventually may cause breakdown or safety issues. In connectors, vibration not only causes deterioration, but also a rapid pushing and pulling on the wire, affecting the long-term stability of the connection. The movement of the wire is often most intense at the equipment’s resonance frequency.

Fretting is another common form of degration caused by mechanical stress and vibration. Fretting is corrosion or wear caused by two surfaces sliding against one another. The combination of vibration and oxidation can lead to fretting, transitory fracture, a coating of oxide, and abrasion, the potential results of which include contact resistance and current fluctuations. Temperature has a significant impact; a higher temperature accelerates fretting corrosion by increasing the oxidation rate. Contact resistance varies over time with an increase in wear, and contacts wear down due to the heat cycle and contact displacement changes.

Industrial connectors need to be rugged enough to provide the reliability and flexibility needed for the demanding environments in which they are installed. They must be able to endure momentary mechanical stress and high contact pressure, as well as constant and long-term vibration.

TE Connectivity Dynamic Series Connectors

TE’s Dynamic Series is a product family that provides a variety of connector solutions, ranging from signal level circuitry through to power circuit connectivity. This series includes connectors designed for installation both inside and outside of cabinets, with all products coming in a rugged package that can withstand the rigors of an industrial setting.

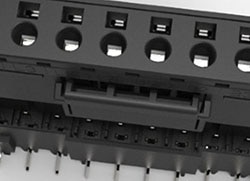

Figure 2: Dynamic series connectors

Source: TE Connectivity

As shown in Figure 2, the Dynamic Series offers wire-to-board, wire-to-panel, and wire-to-wire connectors with diverse housings available to meet most applications. They have a large contact area, which prevents the chance of disconnection over time. They also feature full box contacts with three points of contact to ensure the reliable flow of signal or power.

The Dynamic Series is designed for vibration and shock-exposed applications. A robust locking mechanism prevents the unmating of the connector pair under stress, with additional retention legs to withstand axial pullout forces applied to the harness. An audible locking system ensures that the connection is locked in correctly. The Dynamic Series consists of three types based on application: signal, power, and special components. Sealed IP67-rated connectors are also available.

Table 1 summarizes various examples from the Dynamic Series.

|

Dynamic Series Mini |

With a header height of only 8.7mm, the Dynamic Mini Series connectors have the lowest profile in the Dynamic Series family. The standard pitch is 1.8mm with a rated current maximum of 3A, which is the smallest in the Dynamic family, making it a good solution for signal lines. |

|

Dynamic Series 1000 |

The Dynamic 1000 Series are the smallest connectors for signal lines available in crimp and spring clamp versions. The standard pitch is 2.0mm, the high voltage pitch is 2.5mm, and the spring clamp pitch is 3.5mm - 5A/250V/30-18AWG (UL). |

|

Dynamic Series 2000 |

The Dynamic 2000 Series features a bigger locking lever, increasing usability, and is available in a crimp version. The standard pitch is 2.5mm - 5A/250V/28-18AWG (UL) |

|

Dynamic Series 3000 |

The Dynamic 3000 Series is the main series, offering the most options. Connectors are available in both crimp and spring clamp versions. The standard pitch is 3.81mm, the high voltage pitch is 5.08mm, and the spring clamp pitch is 7.5mm - 15A/600V/28-14 AWG (UL) |

|

Dynamic Series 8000 |

The Dynamic 8000 Series carries the biggest current for power lines within the Dynamic family and is available as wire-to-wire and wire-to-board. Dynamic D8000 connectors with a rated voltage of 1000V AC/DC can carry currents as high as 100A per pin for wire-to-wire and 90A for wire-to-board, and can withstand voltages of up to 3000V AC. The D8000 series have an audible locking system and the unique crimping contact design found on Dynamic standard connectors. With the high-temperature material of the housing, its header is capable of reflow process. |

|

Dynamic Series 7000 |

The Dynamic 7000 Series for high power applications is the biggest connector available in crimp versions. The standard pitch is 16mm - 65A/630V/16-8 AWG (UL). |

|

Dynamic Series 5000 |

The Dynamic 5000 Series is the main power series, offering the most options, and is available in both crimp and spring clamp versions. The standard pitch is 10.16mm, and the spring clamp pitch is 13.1mm - 45A/630V/20-8AWG (UL) |

|

Dynamic Series 4000 |

The Dynamic 4000 Series offers a compact size for applications that are space constrained. Due to the standard pitch of 6.35mm, the current capacity is improved by 32% compared to the Dynamic 5000 series - 24A/600V/16-12AWG (UL) |

Table 1: TE Dynamic Series Connectors

Dynamic Series Connectors vs. Euro-style Terminal Blocks

To demonstrate the differences, TE Connectivity did comparison tests between the Dynamic Series connectors and typical Euro-style terminal blocks. Looking at the contact materials used, the Dynamic Series will outperform a typical terminal block because of its gold plating. A Euro-style terminal block typically uses tin-based plating, which does not prevent oxidation as well as gold. Additionally, gold performs better under contact pressure, with the contact area increasing more under pressure, resulting in a decrease in resistance. Gold also offers higher performance in mating cycles (500 cycles for gold plating vs. 100 cycles of tin plating).

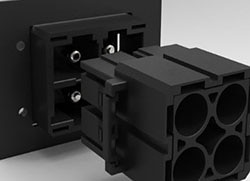

Figure 3 shows a comparison of a typical control cabinet wired with a Euro-style terminal block vs. one wired with Dynamic Series connectors.

Figure 3: Terminal Block (left) vs. Dynamic Series (right) in a Control Cabinet

Source: TE Connectivity

Performance Testing

To determine the performance of Dynamic Series connectors compared to typical Euro-style terminal blocks, TE Connectivity tested the mechanical performance of the common Dynamic D-5000 Series (10.16mm pitch two-piece PCB terminal block with crimp contacts, gold-plated) against Euro-style terminal blocks from two different companies (both 10.16 mm two-piece PCB terminal block with screw clamps, silver-plated).

Five trials, described in Table 2, were conducted, testing the effects of vibration based on the standards listed in IEC 60068-2-6, EIA-364-28F, and MIL-STD-202G. As the trials progressed, more severe vibration profiles were applied and throughout the entire test, the samples were monitored for any discontinuities equal to or exceeding 1 microsecond.

| Trial 1 | IEC 60068-2-6 – Each sample was subjected to simple harmonic motion having the lesser of 0.35mm double amplitude or a 5 g peak amplitude, over a frequency range swept from 10 Hz to 150 Hz at a rate of 1 octave per minute. Total exposure time was 7.5 hours. |

| Trial 2 | EIA-364-28F (Test Condition II) – Each sample was subjected to simple harmonic motion having the lesser of 0.06-inch double amplitude or a 10 g peak amplitude, over a frequency range swept from 10 Hz to 500 Hz over a period of 15 minutes. Sweeps were repeated 12 times for an exposure time of 3 hours each for each axis. Total exposure time was 9 hours. |

| Trial 3 | EIA-364-28F (Test Condition III) – Each sample was subjected to simple harmonic motion having the lesser of 0.06-inch double amplitude or a 15 g peak amplitude, over a frequency range swept from 10 Hz to 2000 Hz over a period of 20 minutes. Sweeps were repeated 12 times for an exposure time of 4 hours each for each axis. Total exposure time was 12 hours. |

| Trial 4 | EIA-364-28F (Test Condition IV) – Each sample was subjected to simple harmonic motion having the lesser of 0.06-inch double amplitude or a 20 g peak amplitude, over a frequency range swept from 10 Hz to 2000 Hz over a period of 20 minutes. Sweeps were repeated 12 times for an exposure time of 4 hours each for each axis. Total exposure time was 12 hours. |

| Trial&nbdp;5 | MIL-STD-202G (Method 204D) – Each sample was subjected to simple harmonic motion having the lesser of 0.06-inch double amplitude or a 30 g peak amplitude, over a frequency range swept from 10 Hz to 2000 Hz over a period of 20 minutes. Sweeps were repeated 12 times for an exposure time of 4 hours each for each axis. Total exposure time was 12 hours. |

Table 2: Descriptions of the Five Trials for TE Connectivity’s Connector Test

Results

Table 3 shows the results from the five trials, showing that the Dynamic Series connectors are more effective at dealing with mechanical vibration than standard Euro-style terminal blocks. Factors contributing to their performance are the vibration-proven housing structure, latching connectors, and gold-plated contact system.

| TE | Company A | Company B | |

| Trial 1 | a | a | Failed |

| Trial 2 | a | a | a |

| Trial 3 | a | a | Failed |

| Trial 4 | a | Failed | Failed |

| Trial 5 | Failed | Failed | Failed |

Table 3: Results from TE Connectivity Tests: Dynamic Series connectors vs. Euro-style Terminal Blocks

Summing Up: Connectors in Industrial Applications

Intelligent industrial applications have become commonplace in factories all over the world, and the connectors delivering their data and power must be rugged enough to withstand harsh factory environments. Euro-style terminal blocks have been the traditional connector for industrial applications; however, to survive the mechanical stress and vibrations of a typical factory floor, a high-performance alternative, such as TE Connectivity’s Dynamic Series, may be better suited.