1. Introduction | 2. Objectives | 3. Scope | 4. Basic Concepts | 5. Analysis | 6. Glossary | Related Components | Test Your Knowledge

Electronic devices are becoming increasingly feature-rich, despite their shrinking size and circuit footprint. These devices also demand to be light in weight, yet sufficiently durable to thrive in environments where heat, vibration, and moving parts tax traditional connections. Flexible printed circuit (FPC) boards and Flexible flat cable (FFC) interconnects offer advantages in these areas and can be used in a range of applications, from medical to automotive, datacom, industrial, and consumer electronics.

FPC boards and FFC interconnects make electronic interconnection simpler and more reliable. The compact nature of flexible circuits offers considerable weight, space, and cost savings over traditional rigid printed circuit boards. In addition, having flexible interconnect cable jumpers in electronic circuits allows them to bend, roll, compress, and adhere to help realize flexible electronics. FPC/FFC interconnects offer board-to-board connections or board-to-display unit connections, and are often used in areas where high signal speed, power distribution, heat, flexibility, or space savings are impediments.

This learning module discusses the benefits of flexible circuits and interconnects, including the types of flat flexible interconnects, their benefits, and applications.

2. Objectives

Upon completion of this module, you will be able to:

Understand the difference between rigid and flexible printed circuits and interconnects

Understand the difference between rigid and flexible printed circuits and interconnects

Explain the innovations occurring in the field of flexible interconnects

Explain the innovations occurring in the field of flexible interconnects

Describe the main types of Premo-Flex flat flexible circuit interconnects

Describe the main types of Premo-Flex flat flexible circuit interconnects

Discuss the applications of FFC interconnects

Discuss the applications of FFC interconnects

A printed circuit board (PCB) is an essential electronic component, as a support for electronic components and a carrier for the electrical connection of electronic components. PCBs can be flexible circuit boards or rigid circuit boards based on different materials. Multiple PCBs can be interconnected as per their circuit schematic to perform the intended functions. The interconnection is achieved by cable jumpers and connectors. Interconnects are either rigid or FFC, depending on different materials. Together, flexible printed circuitry and interconnect cables can provide better performance with increased functionality, higher connectivity, and better environmental performance at a favorable price. In this section, we will get acquainted with the intricacies of rigid vs. flexible circuits and interconnects.

- 3.1 Rigid vs. Flexible Printed Circuits

Rigid printed circuits and flexible printed circuits perform an identical electrical function, but with significant structural and mechanical differences. The most notable difference between rigid and flex PCBs can be inferred from their names. Rigid PCBs are inflexible, while flex PCBs can be bent or otherwise shaped to fit inside the designated system (Figure 1). This fundamental difference requires a flex to be manufactured with different materials, design rules, and different manufacturing processes. Flexible printed circuits have a patterned arrangement of printed circuitry and components that utilizes flexible-based material with or without a flexible cover lay.

Figure 1: Silver Flexible Printed Circuit (FPC) Board Technology (Left) from Molex and Rigid Printed Circuit Board

The low cost of rigid circuit boards justifies their existence. Manufacturers of conventional electronics, particularly consumer electronics, can significantly cut expenses by using rigid circuit boards with greater space availability. However, flexible PCBs are beginning to take market share from rigid circuit boards due to their versatility. FPCs can be the ideal solution for creating complex, small, lightweight products that can survive in harsh environmental conditions. Flexible printed circuits enjoy several advantages over rigid printed circuits, such as:

Connectivity: Flexible circuits provide superior connectivity between other circuit boards, electronic components, and user interfaces in electronic packaging.

Connectivity: Flexible circuits provide superior connectivity between other circuit boards, electronic components, and user interfaces in electronic packaging.

Reduced weight: A lower-weight circuit board results in a lighter end-product, essential in today's electronics market where electronic device designers and consumers prefer compact, lightweight devices.

Reduced weight: A lower-weight circuit board results in a lighter end-product, essential in today's electronics market where electronic device designers and consumers prefer compact, lightweight devices.

Space Reduction: Flex circuits can occupy three dimensions. They can be bent around packaging and even over themselves to fit into a much smaller enclosure.

Space Reduction: Flex circuits can occupy three dimensions. They can be bent around packaging and even over themselves to fit into a much smaller enclosure.

Durability: While rigid PCBs are typically thicker and reasonably robust, flex PCBs absorb shocks and vibrations much more effectively than rigid PCBs. This contributes directly to long-term reliability, product life, and functionality.

Durability: While rigid PCBs are typically thicker and reasonably robust, flex PCBs absorb shocks and vibrations much more effectively than rigid PCBs. This contributes directly to long-term reliability, product life, and functionality.

Thermal Management: Flex does not require cooling from both sides. It quickly dissipates heat and can endure high temperatures.

Thermal Management: Flex does not require cooling from both sides. It quickly dissipates heat and can endure high temperatures.

- 3.2 Rigid vs. Flexible Interconnects

Multiple connection methods can transfer the signal between PCBs or from one PCB to the display unit. Rigid and flat flexible cable (FFC) are the two interconnect methods prevalent in the market today. The process of choosing any interconnect involves weighing the technical needs of the product, its functionality, and the production implications. Rigid interconnects are typically used where PCBs need to be stacked on top of each other or side by side. Armed with either permanent or plug-in connection methods, a profusion of rigid interconnect options are available on the market, with various combinations of length, pin pitches, surface mount, plating types, orientations, and several poles.

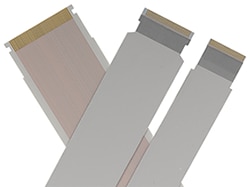

FFC refers to the variety of electrical cabling that is simultaneously flat and flexible. FFCs are straight connections without any components. As a result, FFC interconnects can be used in places where electrical connections require high flexibility, have space constraints, and are subject to vibrations. In addition, they usually take up less space, frequently offer better EMI/RFI suppression, and eliminate wire-coupling issues (Figure 2).

Figure 2: Flat flexible cable (FFC) interconnect jumpers from Premo-Flex(Left) and FFC connectors (right)

Flex jumpers are typically lightweight. Flexible jumpers can be integrated into multiple PCBs assembled in a panel, which can then be broken out and folded into the desired position. They can connect PCBs over a longer distance that would be impossible with a rigid system, and they can be permanently soldered or plugged using FFC connectors.

In the next section of this learning module, we will dive deeply into the innovations occurring in flexible interconnects.

FFC interconnects are available in various pitches, cable lengths, thicknesses, and formats for virtually any industry. When selecting a connector for an application, the consumer/user should also consider the circuit count, plating, life cycle, and contact layout requirements. Premo-Flex Cable Jumpers, part of the Molex Flexible Circuit Solutions product family, offer a wide range of FFC solutions to meet specific needs of circuit designs. The interconnect jumpers are available in an extensive range of custom and off-the-shelf options that enable designers to maximize PCB space, reduce component costs, and provide devices with reliable board-to-board connections. Let us now discuss the types of FFC interconnect in greater detail:

- 4.1 Off the Shelf (OTS) Offerings

Standard, off-the-shelf FFC cable jumpers reduce lead times and tooling costs to the customer. The jumpers are available in different circuit sizes (up to 70) and standard lengths (30 to 305 mm), plus high-temperature ratings up to +105°C. These standard FFC jumper cables offer numerous benefits such as high reliability, a simple assembly process, limitless design-in options, cables with a wide thickness range, and an extended cable life cycle. Furthermore, these cables deliver superior signal integrity and high resistance to vibration and bending.

| A) Series: 15166 0.50mm 4" Type D 16 circuits |

| B) Series: 98266 0.50mm 4" Type A 16 circuits |

| C) Series: 15266 0.50mm 4" Type A 16 circuits |

| D) Series: 15020 0.50mm 4" Type D 16 circuits |

| E) Series: 15015 0.30mm 4" Type A 25 circuits |

Figure 3: The standard OTS offering of Premo-Flex FFC jumpers product line

The complete line is available in the 0.25 mm to 2.54 mm pitch range. FFC jumpers can terminate to ZIF (zero insertion force) and Non-ZIF or Low Insertion Force (LIF) FFC connectors, for a flexible interconnection between two PCBs or a PCB and a display unit. The Type A (same-side) and Type D (opposite-side) contact layouts allow for mirrored contacts in top- and bottom-mount applications. You can quickly determine the cable series number appropriate for your design by referring to the following chart (Table 1).

| Min. Order Series | Pitch (mm) | Circuits | Plating Material | Flex Life Cycles | Insulated Thickness (mm) | End Thickness (mm) | Temp Rating (°C) | Contact Layout Type | Cable Lengths (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 15166 | 0.50 | 6 to 50 | Tin | 2.5M | 0.12 | 0.30 | 105 | A (same side) or D (opposite side) | Standard Lengths: 30.00 to 305.00; Customer Lengths Available |

| 15167 | 1.00 | 4 to 40 | |||||||

| 15168 | 1.25 | 4 to 40 | |||||||

| 98266 | 0.50 | 6 to 50 | 100K | 0.22 | |||||

| 98267 | 1.00 | 4 to 40 | |||||||

| 98268 | 1.25 | 4 to 40 | |||||||

| 15266 | 0.50 | 6 to 50 | 10K | 0.27 | |||||

| 15267 | 1.00 | 4 to 40 | |||||||

| 15268 | 1.25 | 4 to 40 | |||||||

| 15020 | 0.50 | 6 to 50 | Gold | ||||||

| 15039 | 1.00 | 4 to 40 | |||||||

| 15049 | 1.25 | 4 to 40 |

Table 1: Standard Premo-Flex Guide

- 4.2 Standard Offerings with Special Options

Standard FFC interconnects with special options offer jumpers with unique features and design considerations specific to applications and board designs. The Premo-Flex FFC portfolio offers LVDS jumpers, FD19 Notched jumpers, Etched Polyimide jumpers, and EMI Shielded Jumpers in this series.

The LVDS Cable Jumper provides impedance matching and high data speeds with a reliable connection. LVDS (low-voltage differential signal) FFC connectors produce good signal integrity performance over long distances. This makes them a suitable solution for applications such as large displays and high-definition (HD) TVs. At 2 to 10 Gigabits per second (dependent on cable length), these cables deliver higher data speeds than standard FFC.

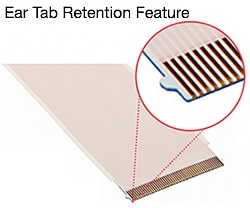

FD19 Notched Cable Jumpers with Ear Tabs provide durable and extra flexible PCB-connection solutions. The cable jumpers offer robust retention due to an ear tab notched feature. This feature ensures proper cable alignment and effective retention with a reliable connection. A simple assembly process and 0.50mm pitch make these components ideal for space-constrained applications and electrical connections between PCBs, display boards, and more.

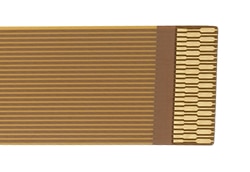

Etched Polyimide Jumpers feature a polyimide substrate and etched-copper technology that achieves the tight tolerances required for reliable connections with 0.30mm pitch micro-miniature FPC connectors. These OTS, ultra-flexible jumpers terminate to Zero Insertion Force (ZIF) FFC connectors and enable designers to use the same PCB pattern on adjoining parallel PCBs.

EMI Shielded FFC Jumpers offers a wide range of standard options for applications requiring protection from electromagnetic interference (EMI). This shielded cable protects against connectivity disturbance due to EMI, signal loss, and potential functional failures. The low-profile, ultra-thin foil Aluminum shielding and fine pitch (0.50mm) are suited for space-constrained applications.

- 4.3 Customized Offerings

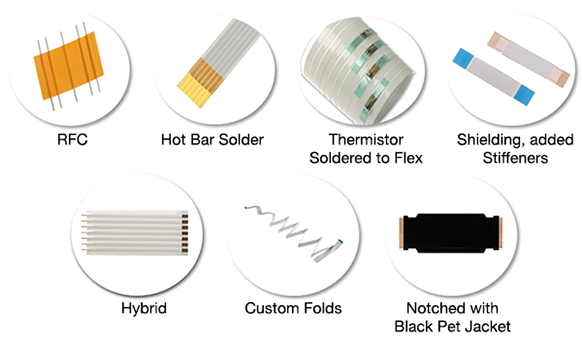

If a design requires specialized attributes, then custom solutions provide multiple capabilities that enable designers to maximize PCB space and reduce component costs. Custom solutions include specific lengths, EMI shielding, folding, stiffeners, and jacketing color. Other options are round flat cables (RFCs) and hot-bar soldering versions that terminate directly to the board and eliminate the need for connectors, which maximizes PCB space, reduces component costs, and provides reliable board-to-board connection. Hybrid options with direct-to-board termination on one end and connector termination on the other are also available.

Figure 4: Premo-flex custom capabilities FFC jumpers

With all its features and benefits, the FFC is on the path to becoming an integral part of future applications. The FFC interconnects initially found widespread use in consumer and computing applications. Computers, notebooks, tablets, cameras and video cameras, DVD and Blu-Ray players, printers and scanners, set-top units, and appliances are some of the well-established products that have benefitted from FFC’s features. FFC is now used in many portable medical devices, and as industrial and transportation equipment evolves to demand better connectivity, this cable type is finding a place in larger applications, as well. The growth in electronic content in automobiles has created new uses for FFC and FPC cables and connectors. The rollout of Industry 4.0 and 5G is heavily dependent on these versatile and powerful cable options.

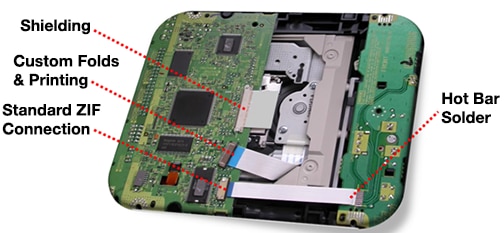

Figure 5 represents one application found in many products. Modern electronics tend to condense more functionality in the same or even a smaller form factor. This unit utilizes multiple FFC solutions from the wide range of FFC interconnect available from Premo-Flex, both custom and OTS. The standard ZIF connection, shielding, customized hot bar solder, folds, and printing allow the solution to improve assembly, reduce weight and space, enhance ruggedness, and eliminate wires and interconnects to reduce failure points and improve reliability.

To understand how FFC interconnects fit in modern industry, let us explore some applications in the next sections.

- 5.1 Automotive

The automotive industry is sustaining a massive transformation, as consumers demand greater functionality from their vehicles. Vehicle systems are now connected with complex electronics that drive modularization, with a significant increase in data sensing systems, Human-Machine Interfaces (HMIs), radars, connected engine compartments, infotainment systems, and cameras requiring multiple PCB and flex assemblies. Although often overlooked in importance, cables and connectors form critical nervous systems and must deliver fast, uninterrupted signal transmissions within the vehicle. FFCs make for simpler and more reliable electronic interconnections.

FFC jumpers’ super-slim and ultra-flexible cable options offer interconnection in confined vehicle spaces. The lightweight feature of flexible interconnections can contribute to an overall vehicle weight reduction and better fuel efficiency. Additionally, flexible cables also protect against ambient noise, electromagnetic interference (EMI), and other signal interference. The Premo-Flex range of standard and customized FFC cables offers plating options, type A and type D contact layouts, customized folds, and splits help for improved routing and vehicle assemblage.

- 5.2 Medical

Today's medical end-users, whether they are professionals or consumers, expect their healthcare devices and wellness delivery systems to be intuitive, lightweight, easy to use, and reliable, regardless of when and where they are utilized. In addition, many new devices are designed to be portable or wearable, implying that they are small and lightweight. Finally, as diagnostic, therapeutic, and monitoring devices continue to coalesce, manufacturers must engage increasingly complex and differentiated supply chains to remain compliant with standards.

FFCs are used in various medical applications, including automated medical equipment, medical robotics, monitoring systems, testing equipment, and human medical devices like hearing aids. These flexible cables are veritable differentiators, making Medtech electronic interconnection simpler, more compact, and better. The Premo-Flex range of standard and customized FFC cables offer LVDS connectors, EMI shielding, and hot bar soldering to solve a combination of high-speed signal integrity, power transmission, EMI protection, and high-voltage isolation required for medical equipment.

Premo-Flex Cables and Easy-On Connectors Products

EMI: Electromagnetic Interference is the interference caused by one electrical or electronic device to another by the electromagnetic fields set up by its operation.

EMI: Electromagnetic Interference is the interference caused by one electrical or electronic device to another by the electromagnetic fields set up by its operation.

HMI: a Human Machine Interface is a user interface or dashboard that connects a person to a machine, system, or device.

HMI: a Human Machine Interface is a user interface or dashboard that connects a person to a machine, system, or device.

Interconnect: A cable or jumper with connectors for board-to-board or board-to-display connection.

Interconnect: A cable or jumper with connectors for board-to-board or board-to-display connection.

LVDS: Low Voltage Differential Signal is a high-speed, long-distance interface over wires. This configuration reduces noise emissions by making the noise more findable and filterable.

LVDS: Low Voltage Differential Signal is a high-speed, long-distance interface over wires. This configuration reduces noise emissions by making the noise more findable and filterable.

LIF: Low Insertion Force sockets reduce the issues of insertion and extraction. They are, however, less reliable than ZIF (zero insertion force).

LIF: Low Insertion Force sockets reduce the issues of insertion and extraction. They are, however, less reliable than ZIF (zero insertion force).

Pitch Range: The spacing of the conductors. The pitch typically refers to the distance from the center of one conductor to the center of its neighboring conductor. FFC cables are available in many pitches.

Pitch Range: The spacing of the conductors. The pitch typically refers to the distance from the center of one conductor to the center of its neighboring conductor. FFC cables are available in many pitches.

RFI: EMI is also called RFI (Radio Frequency Interference). Although EMI and RFI are often used interchangeably, EMI is any frequency of electrical noise, whereas RFI is a specific subset of electrical noise on the EMI spectrum.

RFI: EMI is also called RFI (Radio Frequency Interference). Although EMI and RFI are often used interchangeably, EMI is any frequency of electrical noise, whereas RFI is a specific subset of electrical noise on the EMI spectrum.

ZIF: Zero Insertion Force. This means that no force is exerted on the cable contact during assembly.

ZIF: Zero Insertion Force. This means that no force is exerted on the cable contact during assembly.

*Trademark. Molex is a trademark of Molex Corporation. Other logos, product and/or company names may be trademarks of their respective owners.

Shop our wide range of FFC / FPC connectors, jumper cables, and other interconnect components offered by Premo-Flex.

Test Your KnowledgeBack to Top

Are you ready to demonstrate your knowledge of Flat Flexible Cables (Premo-Flex) and Interconnections? Then take a quick 10-question quiz to see how much you've learned. To earn the Connectors VII Badge, read through the learning module, attain 100% on the Quiz, leave us some feedback in the comments section, and give the learning module a star rating.